Pump station front pool using triangular guide column to control vortexes

A technology of diversion columns and forebays, which is applied in pump stations, waterway systems, drainage structures, etc., and can solve problems such as cavitation, pump vibration, easy backflow and vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is applicable to all kinds of forebays combined with gates and stations, and the drawings are designed according to the requirements of this design.

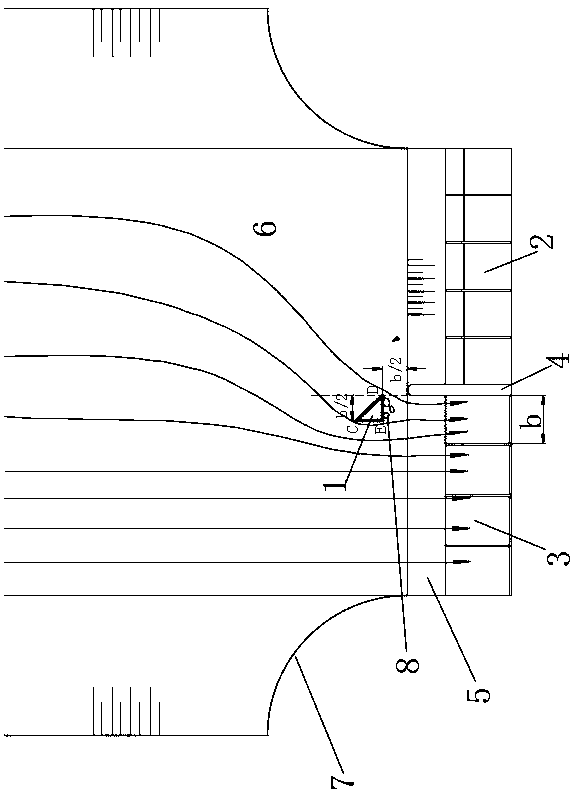

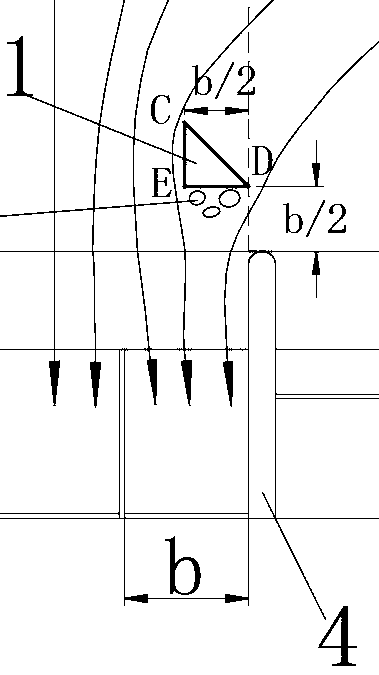

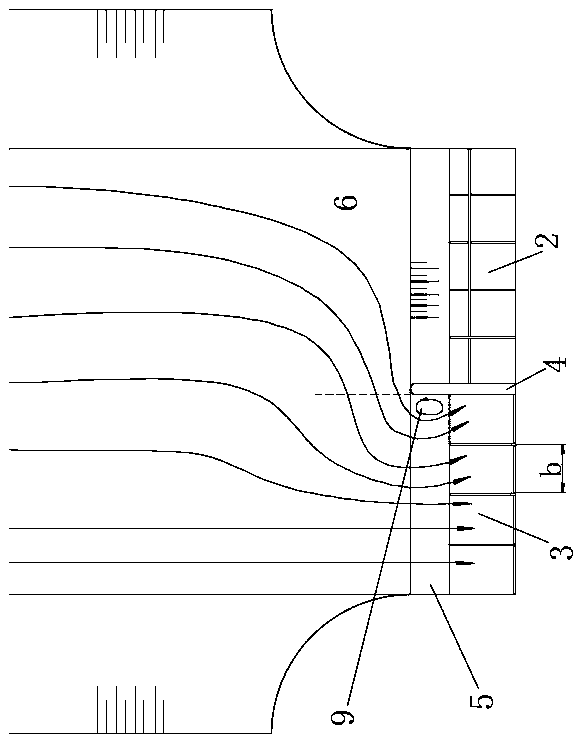

[0024] The forebay of the pumping station using the triangular diversion column to control vortex, including the forebay of the pumping station, the triangular diversion column, the sluice sluice chamber, the diversion river and the pier between the gate stations, and the triangular diversion in the forebay of the pumping station The triangular diversion column is located in front of the pump station inlet pool (flow channel), flush with the extension line of the gate station pier, and its cross-sectional shape is an isosceles right triangle. The top elevation of the triangular diversion column 1 is the same as the highest water level equal.

[0025] Such as figure 1 As shown, the cross section of the triangular diversion column 1 is an isosceles right-angled triangle CDE, the length of the right-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com