Application of early-strength viscosity-reducing type polycarboxylic acid water-reducing agent in preparation of prefabricated member concrete

A technology of concrete and water reducer, which is applied in the field of early-strength viscosity-reducing polycarboxylate water-reducer to prepare prefabricated concrete, which can solve the problems of retardation and high viscosity, low early strength viscosity, and poor durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

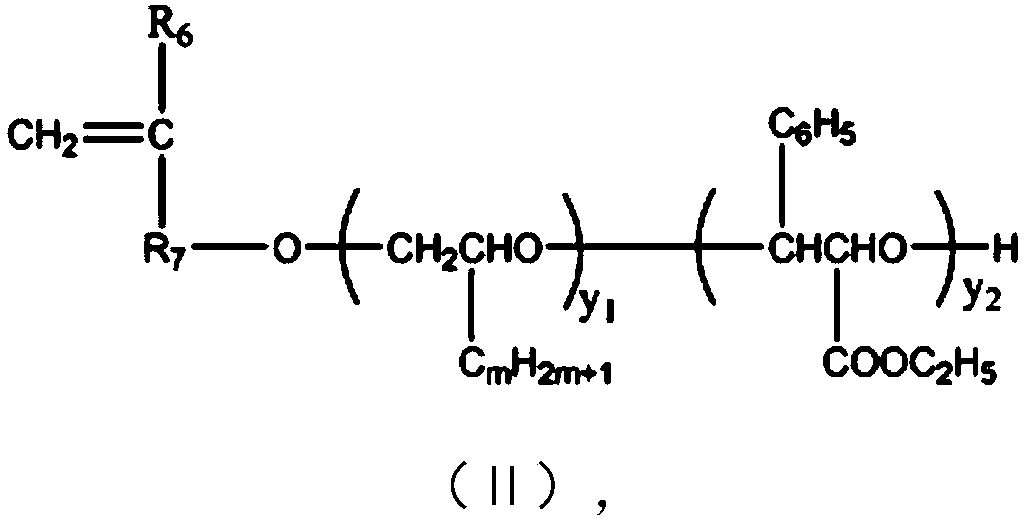

Image

Examples

Embodiment 1

[0067] The preparation method of the early-strength viscosity-reducing polycarboxylate superplasticizer of the present invention, the preparation method comprises the following steps:

[0068] (1) Synthesis of viscosity-reducing active macromonomer D:

[0069] In a four-necked glass flask equipped with a stirrer, a thermometer, a reflux condenser, and a dropping device, add 1 mol of methallyl alcohol, 2 g of sodium hydride, stir under nitrogen protection, and drop 30 mol of ring The oxyalkane was added dropwise in 3 hours, and the reaction was continued at 100°C for 8 hours to obtain the viscosity-reducing active macromonomer D.

[0070] (2) Synthesis of early-strength viscosity-reducing polycarboxylate superplasticizer

[0071] Dissolve reactive monomer B, reactive monomer C, reactive monomer D, reactive monomer E, and an oxidizing agent in water to obtain solution 1, dissolve reactive monomer A and chain transfer agent in water to obtain solution 2, and dissolve the reducin...

Embodiment 2

[0075] The preparation method of the early-strength viscosity-reducing polycarboxylate superplasticizer of the present invention, the preparation method comprises the following steps:

[0076] (1) Synthesis of viscosity-reducing active macromonomer D:

[0077] In a four-necked glass flask equipped with a stirrer, a thermometer, a reflux condenser, and a dropping device, add 1 mol of methallyl alcohol and 2 g of sodium hydride, stir under nitrogen protection, and add 30 mol dropwise at a constant speed at 90 ° C. , Ethyl 3-epoxy 3-phenylpropionate was added dropwise in 3 hours, and the reaction was continued at 100°C for 8 hours to obtain the viscosity-reducing active macromonomer D.

[0078] (2) Synthesis of early-strength viscosity-reducing polycarboxylate superplasticizer

[0079] Dissolve reactive monomer B, reactive monomer C, reactive monomer D, reactive monomer E, and an oxidizing agent in water to obtain solution 1, dissolve reactive monomer A and chain transfer agent ...

Embodiment 3

[0083] The preparation method of the early-strength viscosity-reducing polycarboxylate superplasticizer of the present invention, the preparation method comprises the following steps:

[0084] (1) Synthesis of viscosity-reducing active macromonomer D:

[0085] In a four-necked glass flask equipped with a stirrer, a thermometer, a reflux condenser, and a dropping device, add 1 mol of methallyl alcohol, 2 g of sodium hydride, stir under nitrogen protection, and dropwise add 15 mol of ring Oxyalkane and 15mol ethyl 2,3 epoxy 3-phenylpropionate were added dropwise in 3 hours, and the reaction was continued at 100°C for 8 hours to obtain the viscosity-reducing active macromonomer D.

[0086] (2) Synthesis of early-strength viscosity-reducing polycarboxylate superplasticizer

[0087] Dissolve reactive monomer B, reactive monomer C, reactive monomer D, reactive monomer E, and an oxidizing agent in water to obtain solution 1, dissolve reactive monomer A and chain transfer agent in wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com