A kind of deep dewatering pretreatment process of landfill sludge

A technology of deep dewatering and sewage treatment plant, which is applied in sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc., which can solve the problem of increasing treatment burden, increasing dewatering liquid treatment burden, and excessive dilution and other problems, to achieve the effect of reducing the amount of wastewater treatment, improving the utilization rate of chemicals, and overcoming the dosage of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

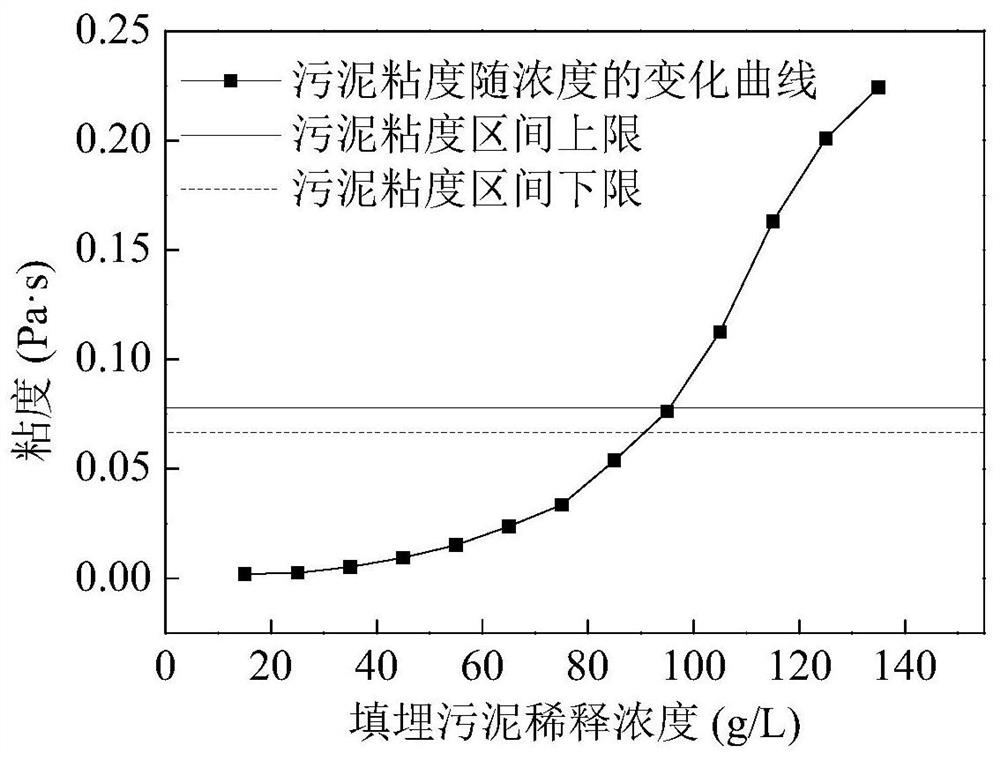

[0039] see figure 1As shown in the process, the landfill sludge with a moisture content of 81.2% was diluted to obtain diluted sludge with concentrations of 135, 125, 115, 105, 95, 85, 75, 65, 55, 45, 35, 25 and 15 g / L. mud. The viscosity of the above-mentioned diluted landfill sludge is measured to obtain a viscosity curve, and the viscosity of the excess sludge (concentration of 52.1g / L) of the sewage plant that produces the landfill sludge is measured to obtain a viscosity change interval, the viscosity interval The relationship with the viscosity curve is as image 3 shown. like image 3 As shown in Fig. 2, the viscosity interval overlaps with the viscosity curve of the diluted landfill sludge. It can be known that referring to the above example, the landfill sludge is also diluted to the concentration of 50.6g / L and 123.4g / L, respectively, and is also diluted with lime The addition of ferric chloride is 9.9% of the dry base of the sludge, and the addition of ferric c...

Embodiment 2

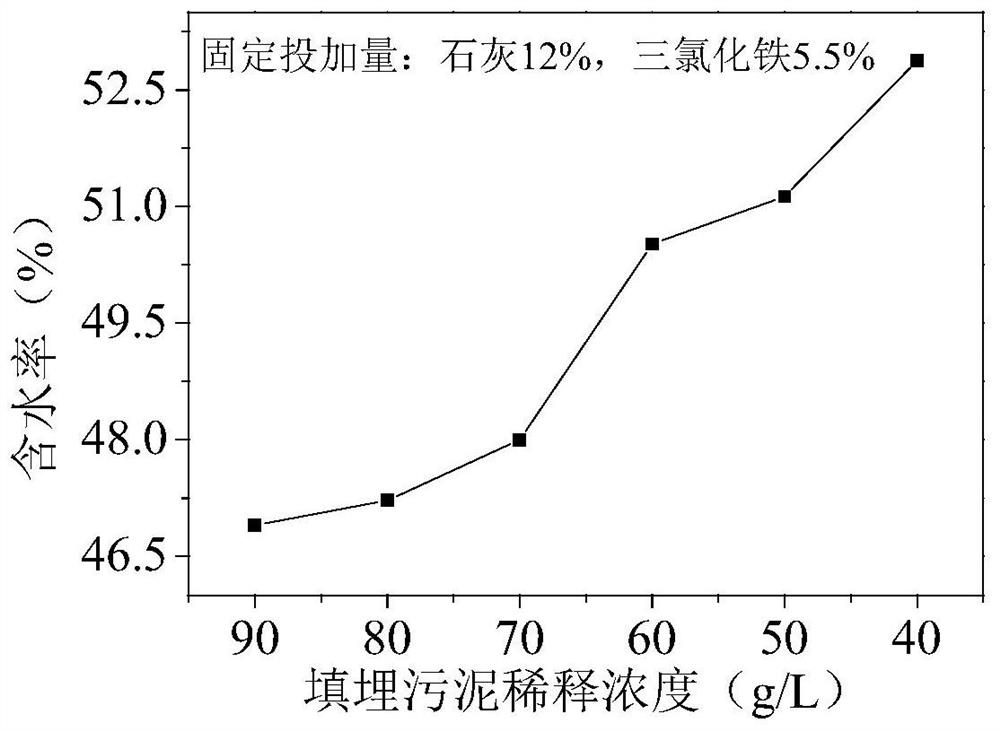

[0042] Referring to the treatment process of Example 1, the effect of excessive dilution on the moisture content of the filter press cake was studied by adding lime and ferric chloride at the same dosage to the diluted landfill sludge with different concentrations. Diluted landfill sludge with concentrations of 90, 80, 70, 60, 50 and 40g / L was subjected to the same conditioning agent addition (lime 12%, ferric chloride 5.5%) based on the sludge dry basis and then filter press experiments, the results of which are figure 2 shown. Depend on figure 2 It can be seen that under the same dosage of chemicals, when the concentration of the diluted sludge is 90g / L, the moisture content of the mud cake after conditioning and dehydration is 46.9%. With the increase of dilution degree, the moisture content of mud cake increases continuously. When the dilution concentration was reduced to 40g / L, the moisture content of the mud cake after conditioning and dehydration was 52.8%. It shows...

Embodiment 3

[0044] according to figure 1 The process flow is used to pretreat landfill sludge. Dilute 0.57 tons of landfill sludge with a moisture content of 80.8±0.7% with sludge dewatering solution to a volume of 1m 3 The moisture content of the landfill sludge was 90.6±0.3%. After adding conditioning agents to the diluted landfill sludge (9.9% of lime and 4.6% of ferric chloride are added according to the dry base of the sludge), the sludge is deeply dewatered by a plate and frame filter press to obtain a mud cake. and 0.7±0.01m 3 sludge dewatering solution. Of which 0.43m 3 It is used for the dilution of landfill sludge, and the remaining dewatering liquid enters the leachate treatment system of the sewage treatment plant for treatment. In this way, the dewatering liquid is recycled to dilute the landfill sludge 5 times and the moisture content of the conditioned mud cake is measured. It can be seen from Table 1 that under the same dosage of chemicals, with the increase of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com