Pull-open printed matter and covering

A printing and covering technology, applied in the printing field, can solve problems such as unstable quality, complicated manufacturing process, and time-consuming, and achieve the effects of saving opening time, simple manufacturing process, and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

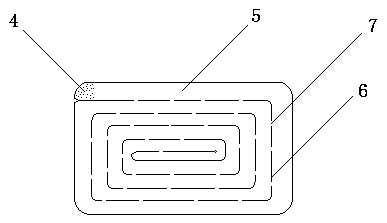

[0063] make a shape like Figure 8 Pull-out print shown - Promotional Redemption Label.

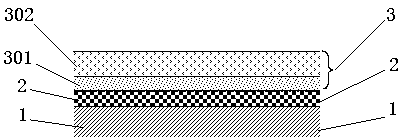

[0064] first step, such as figure 1 ,Such as figure 2 , image 3 , Figure 10 As shown, select a 16 μm thick opaque PE film (302), such as an aluminized film, and coat a layer of 2 μm thick transparent release agent layer (9) on the inner side of the film (302) for use.

[0065] In the second step, choose 80g / cm 2 The coated paper self-adhesive material is used as the base layer (1), and the unique and random anti-counterfeiting reward code and other confidential information printing layer (2) is printed on the surface of the coated paper.

[0066] In the third step, the film (302) coated with the transparent release agent layer (9) on the inner side is coated on the surface of the coated paper with laminating glue, so as to cover and seal the confidential information printing layer (2).

[0067] The fourth step is to die-cut the PE opaque film (302) with a laser die-cutting machin...

Embodiment 2

[0074] make a shape like Figure 9 Pull-out print shown - instant lottery tickets.

[0075] first step, such as figure 1 , image 3 , Figure 5 As shown, select a 16 μm thick opaque PE film (302), such as an aluminized film, and coat a layer of 2 μm thick transparent release agent layer (9) on the inner side of the film (302) for use.

[0076] In the second step, choose 160g / cm 2 The cardboard is used as the base layer (1), and the printing layer (2) of confidential information such as awards is printed on the surface of the cardboard.

[0077] In the third step, the film (302) coated with the transparent release agent layer (9) on the inner side is covered with laminating glue on the surface of the cardboard, so as to cover and seal the confidential information printing layer (2).

[0078] The fourth step is to die-cut the PE opaque film (302) with a die-cutting machine such as Figure 5 slit (6) as shown.

[0079] The fifth step, in order to increase the difficulty of...

Embodiment 3

[0083] Make a hierarchy like Figure 10 Pull open cover as shown.

[0084] first step, such as Figure 10 As shown, choose a 35 μm thick opaque PET film (302), for example, choose an aluminized film molded with laser graphics, and sequentially coat a 2 μm thick transparent release agent layer (9) on the inside of the film (302) and The self-adhesive layer (10) is used as a transparent transfer layer (301).

[0085] Of course, a transparent layer for other purposes can also be inserted between the transparent release agent layer (9) and the self-adhesive layer (10). For example a transparent protective layer.

[0086] Preferably, the transparent release agent layer ( 9 ) can be printed as a transparent release agent layer ( 9 ) with characters or patterns (such as the words "opened").

[0087] In the second step, first coat a self-adhesive layer (10) on the transparent release agent layer (9) inside the film (302), and then attach the release base paper layer (11).

[0088...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com