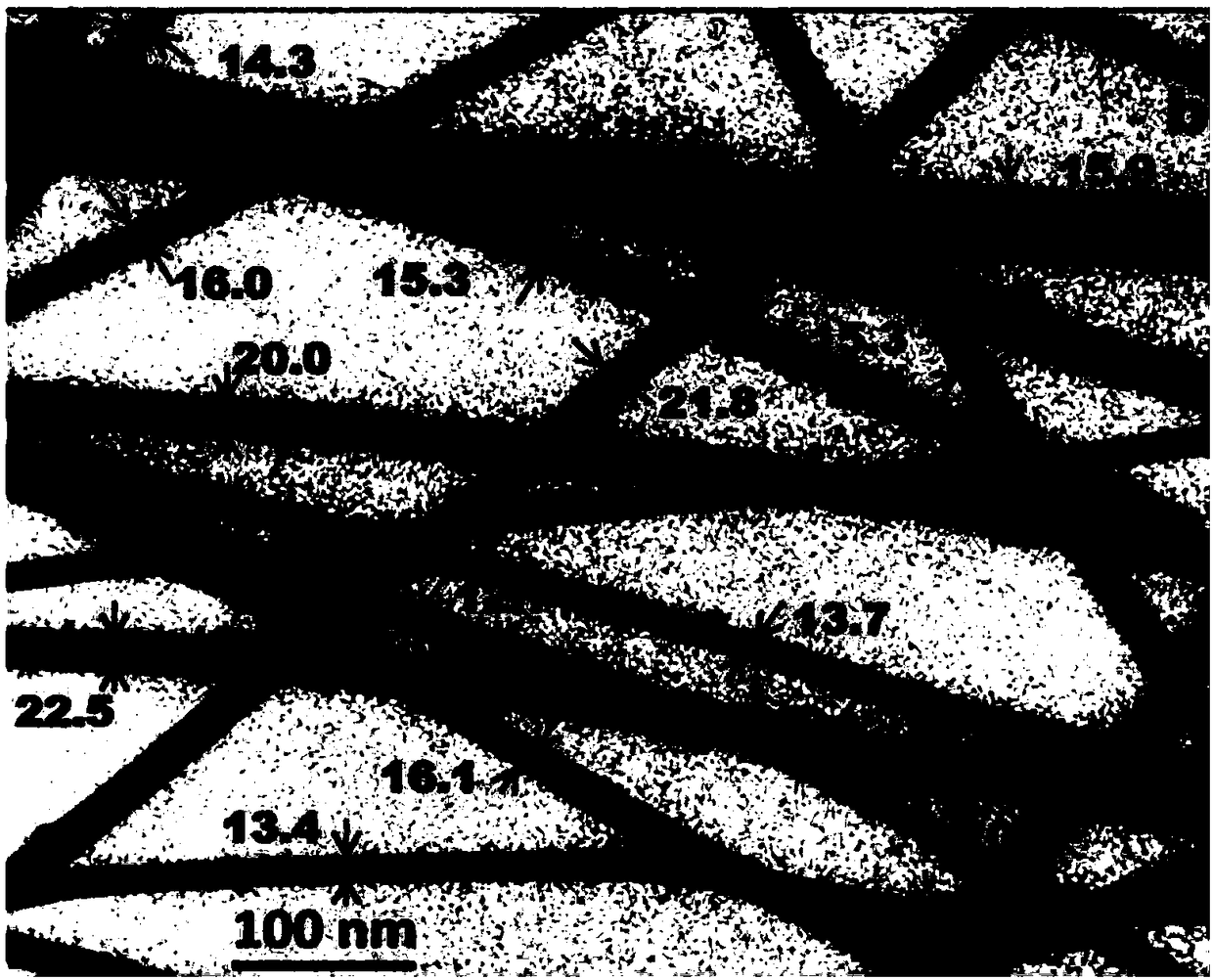

Method for large-batch synthesizing and high-efficiency purifying of superfine silver nano wires

An ultra-fine silver, high-volume technology, applied in nanotechnology and other directions, can solve the problems of difficult to guarantee product quality, difficult process control, and many impurities in nanoparticles, and achieve the effect of stable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for large-scale synthesis and efficient purification of ultrafine AgNWs, comprising the following steps:

[0030] (1) prepare the ethylene glycol (EG) solution of NaCl, NaBr, concentration is respectively 210mM and 220mM;

[0031] (2) Add 3.6L (4.02kg) EG into the three-necked flask, and put in 24.0g PVP (molecular weight 1300000) and 16.2g AgNO 3 , after mixing and dissolving, add 72ml NaCl solution and 48ml NaBr solution, pass N 2 , after heating up to 165°C, stop stirring, N 2 Continue to react in the atmosphere for 1.0h, then cool naturally to room temperature, add deionized water to the reaction solution, reduce the viscosity of the reaction solution to 6cP;

[0032] (3) Transfer the reaction solution to a centrifuge bottle, and centrifuge at 800rpm for 20min. After removing the sediment, the supernatant continues to centrifuge at 800rpm for 20min, and remove the sediment again;

[0033] (4) After repeating step (3) 6 times, completely remove the larg...

Embodiment 2

[0037] A method for large-scale synthesis and efficient purification of ultrafine AgNWs, comprising the following steps:

[0038] (1) prepare the ethylene glycol (EG) solution of KCl, KBr, concentration is respectively 200mM and 200mM;

[0039] (2) Add 3.6L (4.02kg) EG to the three-necked flask, and put in 24.0g PVP (molecular weight 1300000) and 16.2g AgNO 3 , after mixing and dissolving, add 80ml NaCl solution and 36ml NaBr solution, pass N 2 , after heating up to 165°C, stop stirring, N 2 Continue to react in the atmosphere for 1.5h, then naturally cool to room temperature, add deionized water to the reaction solution, reduce the viscosity of the reaction solution to 10cP;

[0040] (3) Transfer the reaction solution to a centrifuge bottle, and centrifuge at 1200rpm for 15min. After removing the sediment, continue the centrifugation of the supernatant at 1200rpm for 20min, and remove the sediment again;

[0041] (4) After repeating step (3) 7 times, completely remove the ...

Embodiment 3

[0045] A method for large-scale synthesis and efficient purification of ultrafine AgNWs, comprising the following steps:

[0046] (1) Preparation of CaCl 2 , MgBr 2 The ethylene glycol (EG) solution of concentration is respectively 100mM and 300mM;

[0047] (2) Add 3.6L (4.02kg) EG to the three-necked flask, and put in 10.05g PVP (molecular weight 360000) and 10.05g AgNO 3 , after mixing and dissolving, add 180ml KCl solution and 20ml KBr solution, pass N 2 , after heating up to 160°C, stop stirring, N 2 Continue to react in the atmosphere for 3.0h, then cool naturally to room temperature, add deionized water to the reaction solution, reduce the viscosity of the reaction solution to 20cP;

[0048] (3) Transfer the reaction solution to a centrifuge bottle, and centrifuge at 1100rpm for 30min. After removing the sediment, the supernatant continues to centrifuge at 1200rpm for 30min, and remove the sediment again;

[0049] (4) After repeating step (3) 5 times, completely rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com