Preparing method for spherical metal powder for additional material manufacturing

A metal powder and additive manufacturing technology, applied in metal processing equipment, additive processing, transportation and packaging, etc., can solve problems such as cost and efficiency constraints, improve powder morphology, improve fluidity, and reduce adhesion and collision problems. The effect of the chance of solidifying the coarse meal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Adopt the following steps to prepare copper alloy powder for selective laser melting (SLM):

[0023] Step 1: Melting the metal or alloy raw material to obtain a metal melt;

[0024] Step 2: Gas atomization powder making, the metal melt is sent to the atomizer to atomize into metal droplets, the atomizer is equipped with a charge supply device, and the metal droplets are charged with the charge supply device charges of the same polarity;

[0025] Step 3: The electrostatic field controls the falling powder, and the two sides of the atomization area extend to the bottom to set up a horizontal electrostatic field composed of positive and negative electrodes;

[0026] Wherein, the gas pressure of the atomizer and the field strength of the electrostatic field are controlled according to the material of the metal powder, so that under the action of the electric field force, gravity and the thrust of the atomized gas, the solidified fine powder with the same polarity will be f...

Embodiment 1

[0029] The control strategy in Example 1 is: according to the CuSn10 alloy material, the atomization pressure is set to 4.0MPa, and the electric field strength is 800V / m, the purpose is to easily reduce the bonding of 0-25μm fine particle powder to unsolidified large particles.

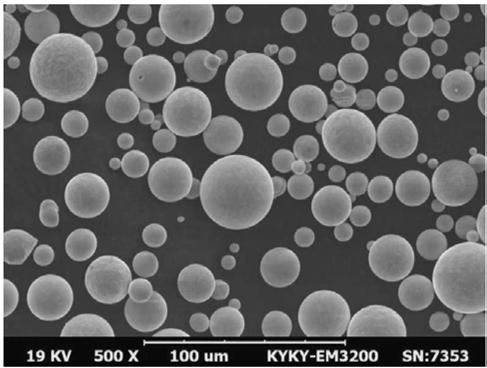

[0030] The CuSn10 powder that present embodiment one obtains is as figure 1 shown by figure 1 It can be seen that the powder has good sphericity and the content of satellite powder is extremely low. The average powder sphericity is ≥0.95, the average particle size is 26.4 microns, the fluidity is 12.5S / 50g, and the bulk density is 4.8g / cm. 3 , After the treatment is finished, the powder is obtained in the collector and sieved into a finished powder of 10-45 μm. The powder has good fluidity during the printing process, the formed parts have little deformation, the structure is uniform, and the mechanical properties meet the requirements of use.

Embodiment 2

[0032] Adopt the following steps to prepare aluminum alloy powders for selective laser melting (SLM):

[0033] Step 1: Melting the metal or alloy raw material to obtain a metal melt;

[0034] Step 2: Gas atomization powder making, the metal melt is sent to the atomizer to atomize into metal droplets, the atomizer is equipped with a charge supply device, and the metal droplets are charged with the charge supply device charges of the same polarity;

[0035] Step 3: The electrostatic field controls the falling powder, and the two sides of the atomization area extend to the bottom to set up a horizontal electrostatic field composed of positive and negative electrodes;

[0036] Wherein, the gas pressure of the atomizer and the field strength of the electrostatic field are controlled according to the material of the metal powder, so that under the action of the electric field force, gravity and the thrust of the atomized gas, the solidified fine powder with the same polarity will b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com