Filter capsule compressive strength detecting system and filter capsule compressive strength continuous detecting method

A compressive strength and detection system technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve problems such as broken beads, achieve high detection efficiency, save manpower, and improve detection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

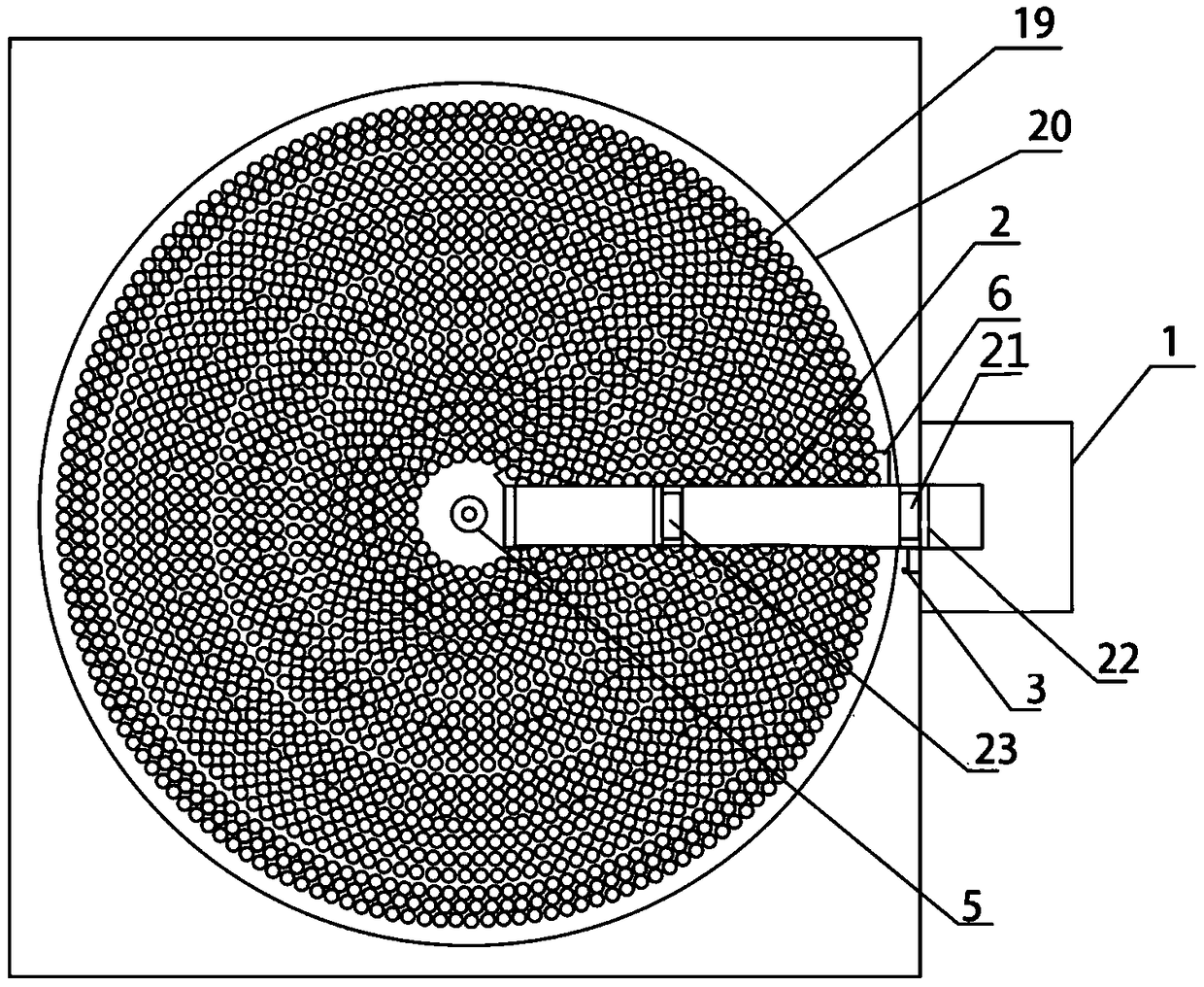

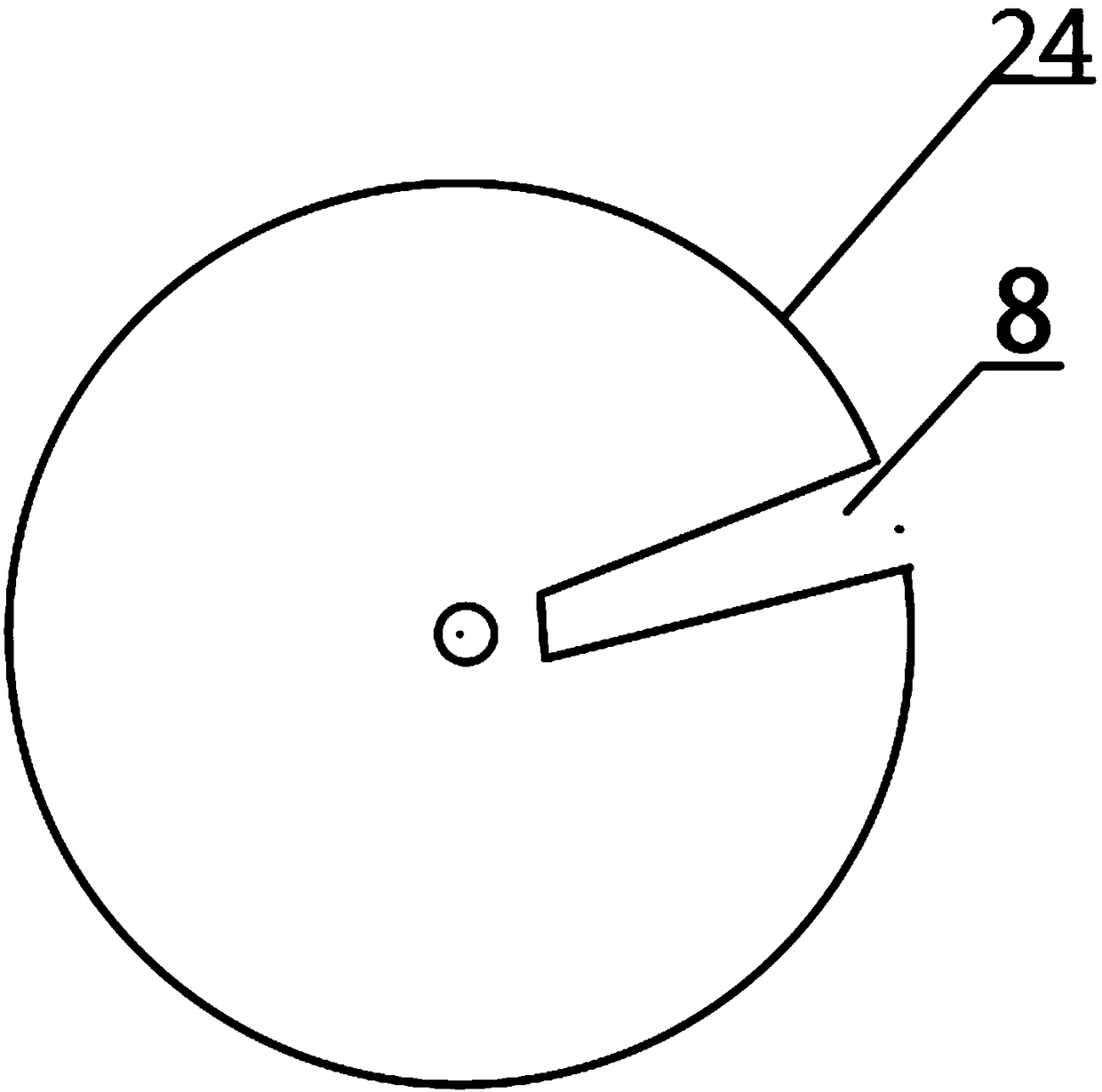

[0044] as attached figure 1 , 2 As shown in and 3, the explosive bead compressive strength detection system includes a sealed box, and also includes a pressurizing system, a feeding system, a material spreading system, a receiving system, a sealing system, a cleaning system, an alarm system and a control system. The pressurizing system pressurizes the device, and the sealing system ensures the air tightness of the device. The feeding system and the spreading system realize that the explosive beads are spread on the set position of the turntable. When the detection is completed, the collecting system collects the explosive beads, and the cleaning system is responsible for The turntable is clean and tidy, the alarm system ensures that the device can operate effectively, and the control system realizes the controllable operation of the device throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com