Method for loading metal organic skeleton structure with noble metal nano-particles

A metal-organic framework and nanoparticle technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problems of cumbersome operation steps and long preparation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of nanocomposite structures based on one-step method of loading noble metal nanoparticles in MOFs.

[0023] (1) By reducing Cu 2+ The method of hydroxy complexes to obtain cuprous oxide.

[0024] (2) Disperse cuprous oxide in N,N-dimethylacetamide (DMA) to form a 0.15mg / ml cuprous oxide DMA dispersion, and introduce a concentration of 80mM into the cuprous oxide DMA dispersion Trimellitic acid ethanol solution, and finally inject 100 microliters of 10mM chloroauric acid (HAuCl 4 ) ethanol solution, the mixed system was evenly mixed by shaking, and left to stand for 30 minutes. The obtained product was separated by centrifugation, washed 3 times with ethanol, and vacuum-dried at 50 degrees for 10 hours to obtain the MOFs nanocomposite structure supported by Au nanoparticles.

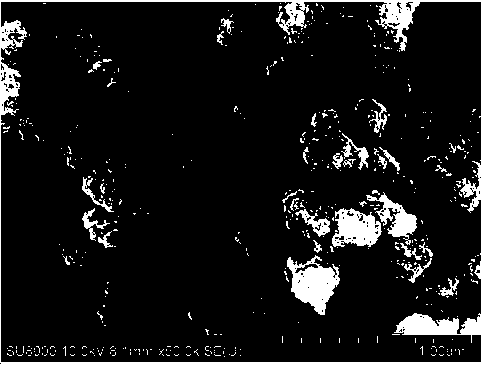

[0025] The scanning electron microscope picture of the reducing template cuprous oxide of the present embodiment is as follows figure 2 Shown; The scanning electron microscope pictu...

Embodiment 2

[0027] Preparation of nanocomposite structures based on one-step method of loading noble metal nanoparticles in MOFs.

[0028] (1) By reducing Cu 2+ The method of hydroxy complexes to obtain cuprous oxide.

[0029] (2) Disperse cuprous oxide in N,N-dimethylacetamide (DMA) to form a 0.15mg / ml cuprous oxide DMA dispersion, and introduce a concentration of 80mM into the cuprous oxide DMA dispersion Trimellitic acid ethanol solution, and finally inject 100 microliters of 10mM chloroplatinic acid (H 2 PtCl 6 ) ethanol solution, mix the mixed system evenly by shaking, and let it stand for 30 minutes. The obtained product is separated by centrifugation, washed 3 times with ethanol, and vacuum-dried at 50 degrees for 10 hours to obtain a Pt nanoparticle-loaded MOFs nanocomposite structure.

Embodiment 3

[0031] Preparation of nanocomposite structures based on one-step method of loading noble metal nanoparticles in MOFs.

[0032] (1) By reducing Cu 2+ The method of hydroxy complexes to obtain cuprous oxide.

[0033] (2) Disperse cuprous oxide in N,N-dimethylacetamide (DMA) to form a 0.15mg / ml cuprous oxide DMA dispersion, and introduce a concentration of 80mM into the cuprous oxide DMA dispersion Trimellitic acid ethanol solution, finally inject 100 microliters of 10mM potassium chloropalladate (H 2 PtCl 6 ) solution, mix the mixed system evenly by shaking, and let it stand for 30 minutes. The obtained product is separated by centrifugation, washed 3 times with ethanol, and vacuum-dried at 50°C for 10 hours to obtain a MOFs nanocomposite structure supported by Pd nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com