Manufacturing method of lithium ion battery high-compaction density pole plate

A technology of lithium ion battery and manufacturing method, which is applied in the field of designing battery pole piece manufacturing, can solve the problems of pole piece becoming hard and flexible, affecting product quality, and uneven surface curling, reducing internal resistance, shortening drying time, volume The effect of increasing specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

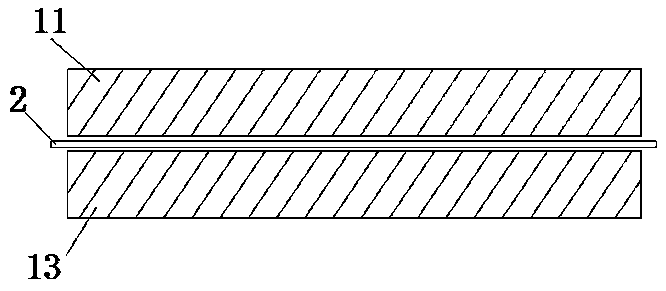

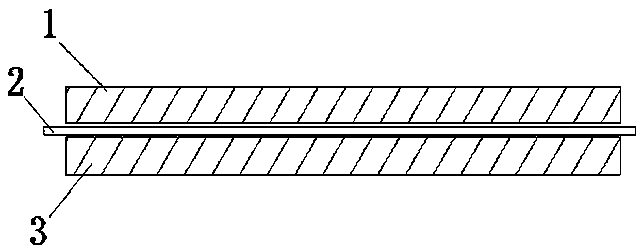

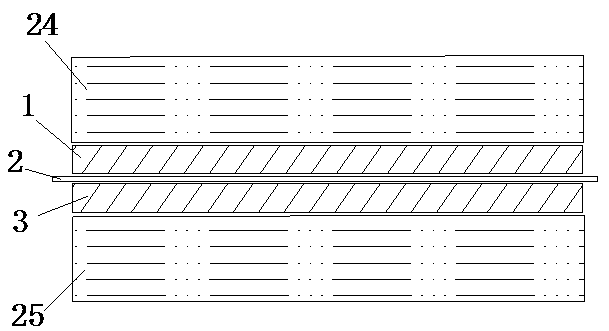

Method used

Image

Examples

Embodiment 1

[0023] Original technology: positive electrode one-time coating process surface density 21mg / cm 2 , gram capacity 164mAh / g, compaction 4.10g / cm 3 , Design capacity 5542mAh.

[0024] The present invention: the positive electrode is coated twice, and the positive electrode surface density of the first coating is 10.5mg / cm 2 , which is 48% of the designed areal density, and the compacted density is 4.10 g / cm 3 , the surface density of the second coating positive electrode is 11.0 mg / cm 2 , which is 52% of the designed areal density, and the compacted density is 4.20 g / cm 3 , the overall compacted density of the pole piece is 4.20 g / cm 3 , the design capacity is 5647mAh, and the capacity is increased by 1.9% compared with the one-time coating process.

[0025] Table 1 Effect of secondary coating on battery performance

[0026]

[0027] The present invention achieves the purpose of maximum overall compaction and increased capacity by coating the positive electrode twice, a...

Embodiment 2

[0029] Original technology: positive electrode one-time coating process surface density 21mg / cm 2, gram capacity 164mAh / g, compaction 4.10 g / cm 3 ; Negative electrode coating surface density 10.90mg / cm 2 , gram capacity 345mAh / g, compaction 1.67 g / cm 3 , Design capacity 5542mAh.

[0030] The present invention: the positive electrode is coated twice, and the surface density of the positive electrode after one coating is 2.15 mg / cm 2 , which is 10% of the designed areal density, the compacted density is 4.10 g / cm3, and the surface density of the secondary coated positive electrode is 19.35 m g / cm 2 , which is 90% of the designed areal density, and the compacted density is 4.20 g / cm 3 , the overall compacted density of the pole piece is 4.20 g / cm 3 ;

[0031] Negative electrode secondary coating: once coated negative electrode double-sided density 5.45 mg / cm 2 , compacted density 1.67 g / cm 3 , the double-sided density of the second coating is 5.95 mg / cm 2 , compaction 1....

Embodiment 3

[0036] Original technology: positive electrode one-time coating process surface density 21mg / cm 2 , gram capacity 164mAh / g, compaction 4.10 g / cm 3 ; Negative electrode coating surface density 10.90mg / cm 2 , gram capacity 345mAh / g, compaction 1.67 g / cm 3 ; Design capacity 5542mAh.

[0037] In the present invention: multiple coatings on the positive electrode: once coated, the surface density of the positive electrode is 3.23 mg / cm 2 , which is 15% of the designed areal density, the compacted density is 4.10 g / cm3, and the surface density of the secondary coated positive electrode is 8.6 mg / cm 2 , which is 40% of the design area density, and the compacted density is 4.20g / cm 3 , three-time coated positive surface density of 9.76 mg / cm 2 , which is the design surface density of 45%, and the compacted density of 4.20 g / cm 3 , the overall compacted density of the pole piece is 4.20 g / cm 3 ;

[0038] Multiple coatings on the negative electrode: once coated, the density on bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com