Trench insulated gate bipolar transistor device and generating method thereof

A bipolar transistor, insulated gate technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as low gate-source voltage and thin gate oxide thickness at the bottom of trenches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

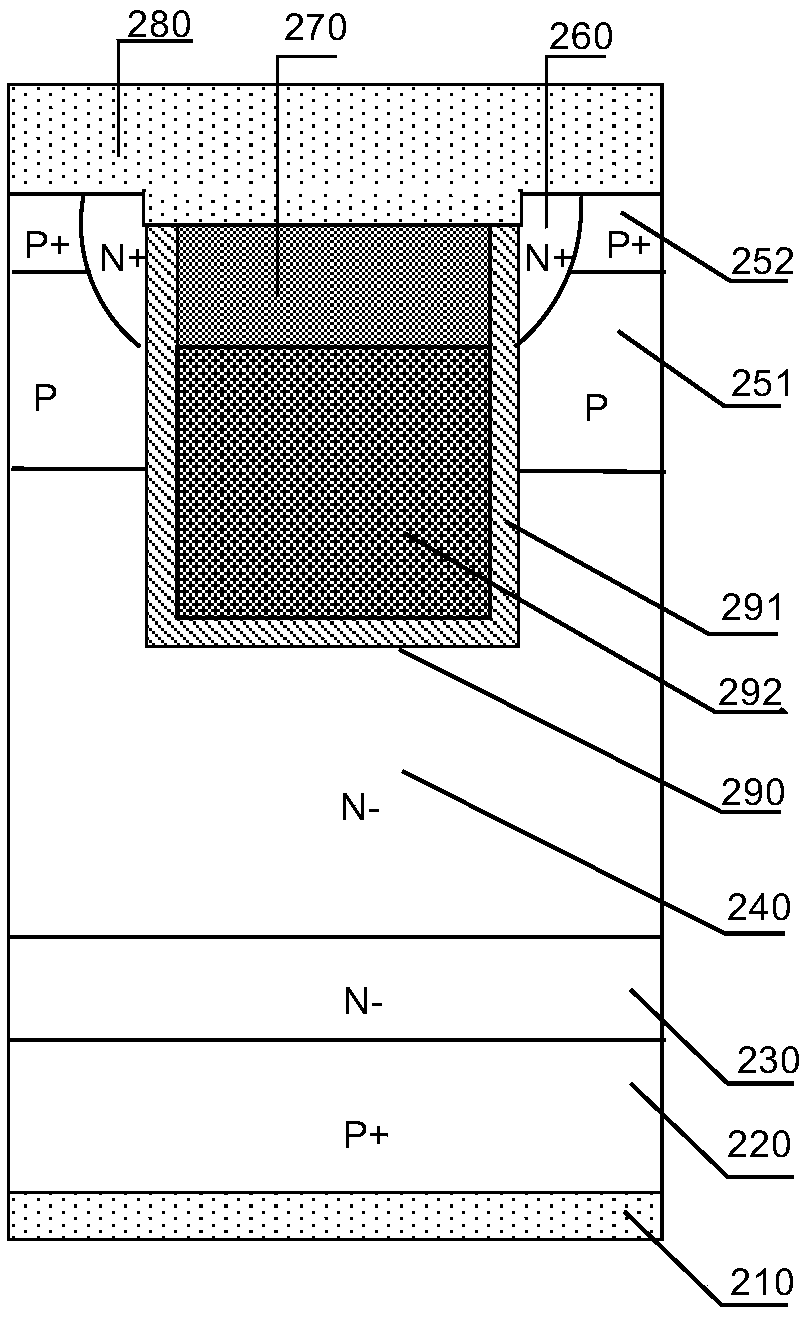

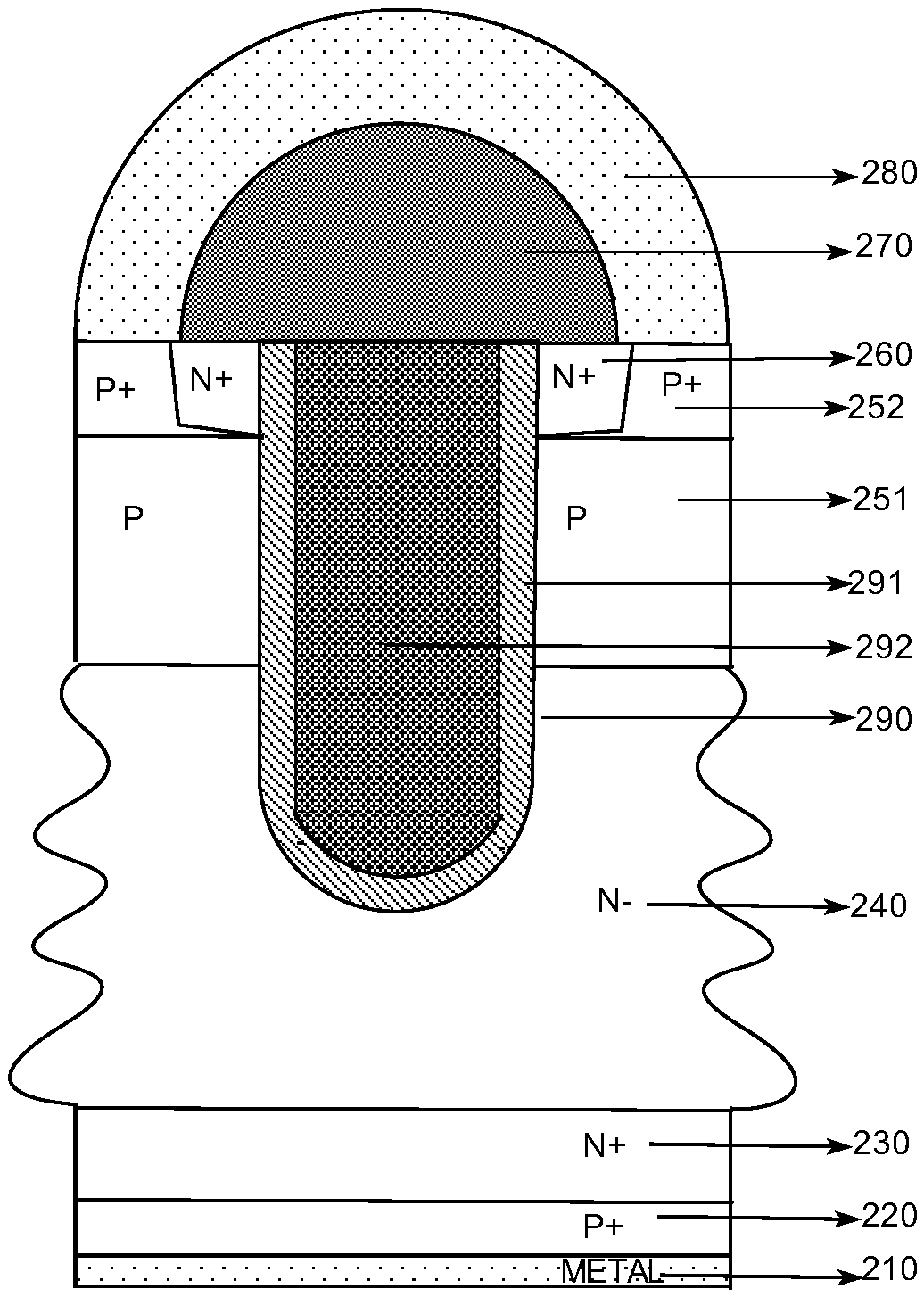

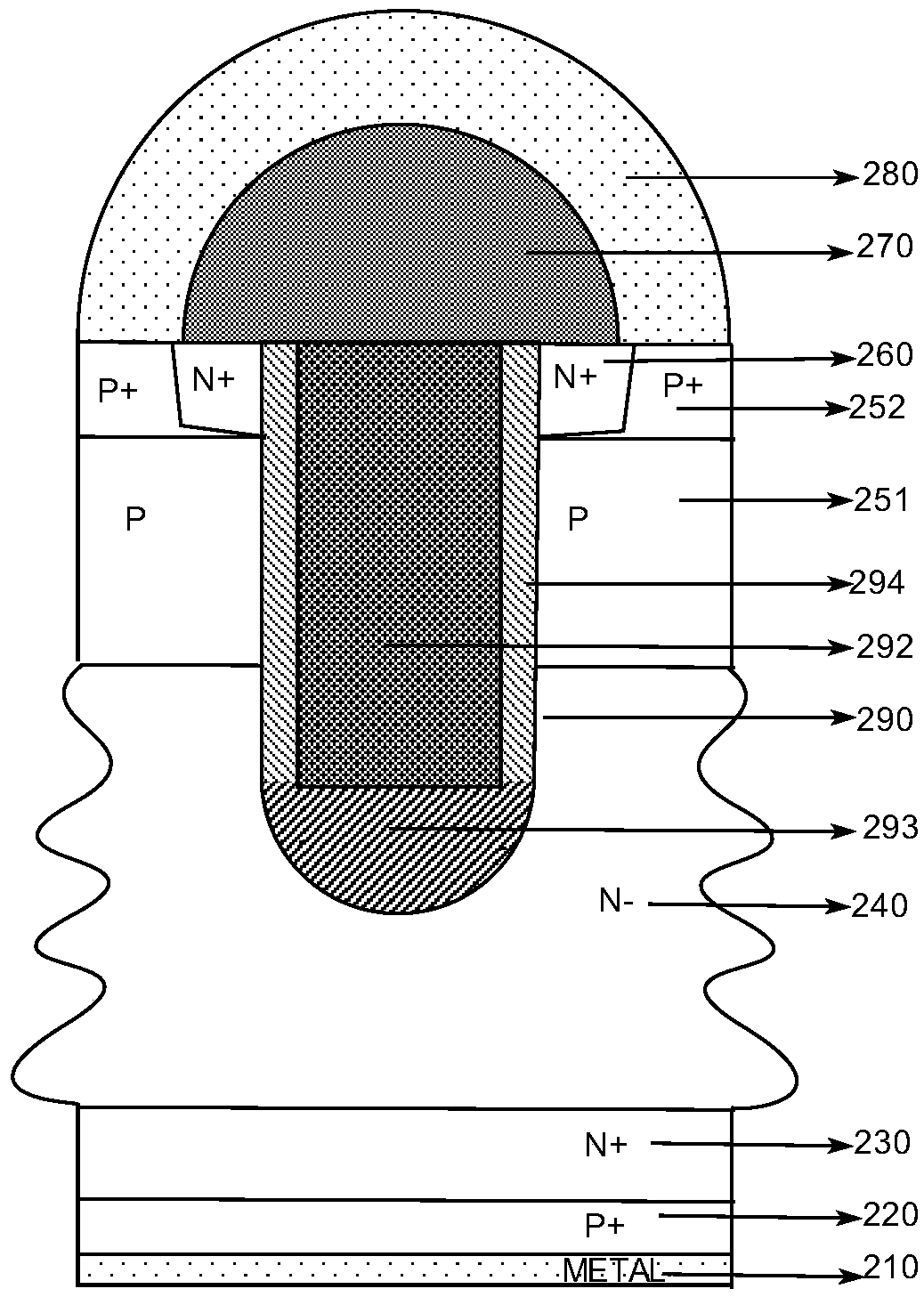

[0078] The application will be described in further detail below in conjunction with the accompanying drawings.

[0079] Such as image 3 As shown, the present application provides a trench insulated gate bipolar transistor device, comprising: a trench region 290, a gate oxide film 293 located at the bottom of the trench region 290, and a sidewall of the trench region 290 Gate oxide film 294, polysilicon gate 292, front emitter metal layer 280, silicon dioxide insulating dielectric layer 270, N+ emitter 260, P-type base region 251, P+ contact region 252, N-type base region 240, N-type The field termination region 230 and the P-type collector 220, the back collector metal layer 210, wherein,

[0080] The P-type base region 251 is formed on the surface of the N-type base region 240;

[0081] The polysilicon gate 292 is grown in the trench region 290, and the polysilicon gate 292 is a trench structure, which runs through the P-type base region 251 and the N-type base region 240...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com