Optimized and upgraded waste heat utilization Kalina cycle power generation system

A Kalina cycle and power generation system technology, applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve problems such as reduction, waste efficiency, and high-pressure potential energy loss of lean ammonia solution, so as to avoid throttling loss and improve production efficiency. Functional ability, improvement of working ability and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

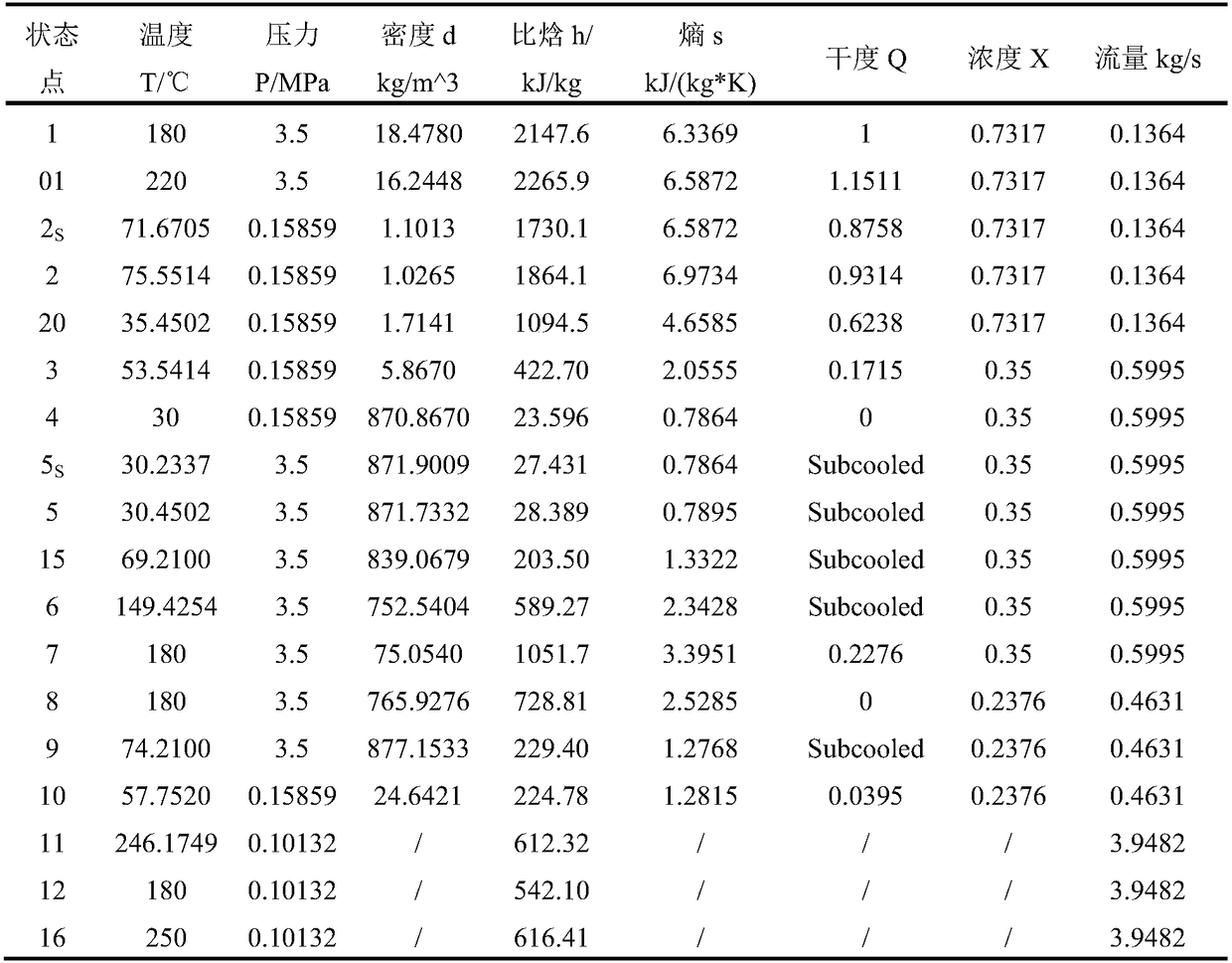

[0019] combine figure 1 , the composition of the present invention includes: evaporator 01, separator 02, superheater 03, steam turbine 04, high temperature regenerator 11, low temperature regenerator 06, two-phase expander 10, mixer 07, condenser 08, working medium Pump 09, generator 05 and circulating working medium ammonia water mixture. The overall circulation process is as follows: the basic ammonia solution enters the separator 02 after passing through the evaporator 01, and the rich ammonia vapor and the lean ammonia solution are separated by the separator 02, and the rich ammonia vapor passes through the superheater 03 and is superheated by a waste heat source of 250°C to a temperature of Higher working steam, the superheated ammonia-rich steam enters the steam turbine 04 to fully expand to do work, and then drives the generator to generate electricity to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com