Automatic coal mining method based on host computer planning

A coal mining method and computer technology, which is applied in the field of automatic coal mining based on the planning of the host computer, can solve the problems of impossible to predict the changes of the top and bottom of the working face, unusable, manual demonstration of knives, etc., so as to achieve visualization and adaptability. The effect of strong performance and low level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

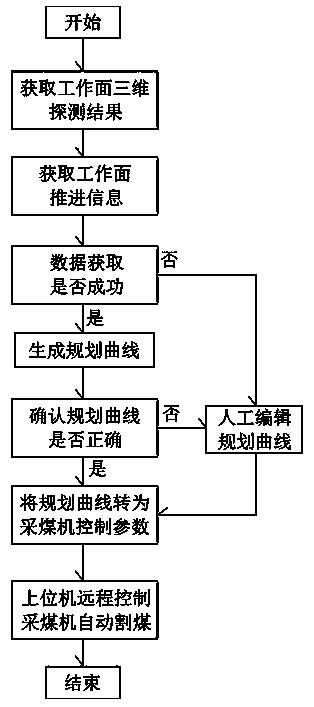

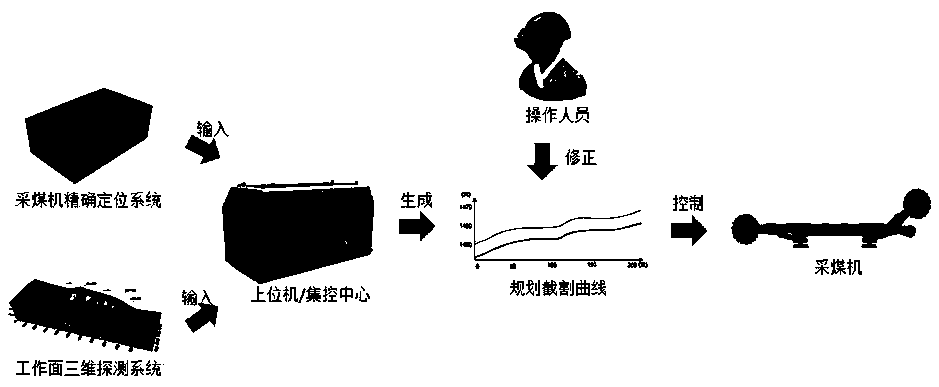

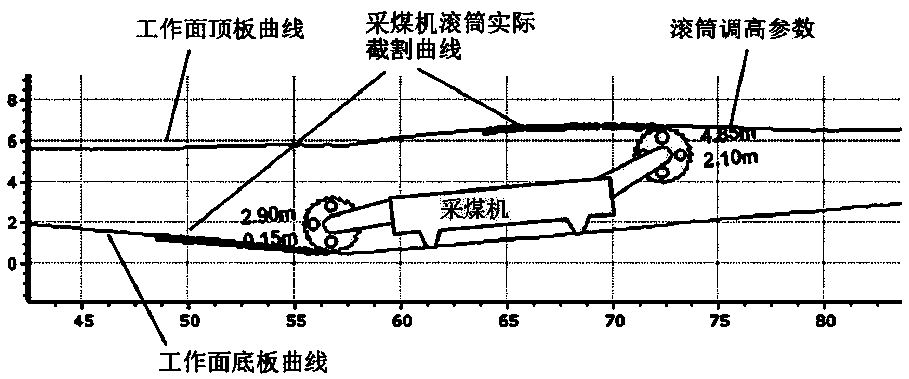

[0028] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

[0029] Such as Figure 1-3 As shown, the automatic coal mining method based on upper computer planning of the present invention includes a three-dimensional detection system for a working face, an accurate positioning system for a coal mining machine, an upper computer, and a coal mining machine that supports remote control functions (for example, developed by Tiandi Technology Shanghai Mining Equipment Co., Ltd. Co., Ltd. MG300 / 720-AWD3 type AC traction shearer); follow the steps below:

[0030] In the first step, the upper computer obtains the top and bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com