Tension sensor for liquid ammonia mercerizing machine

A technology of tension sensor and liquid ammonia mercerizing, which is applied in the direction of tension measurement and processing of textile material carriers, etc., can solve the problems of affecting the quality of fabric processing, poor contact between strain gauges and fixed interfaces, and errors in measurement signals, so as to eliminate the problem of poor contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

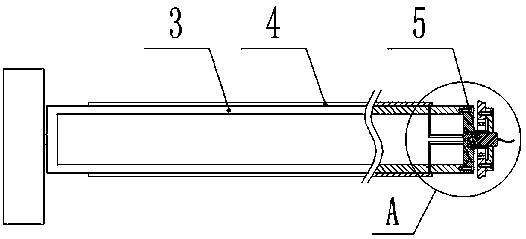

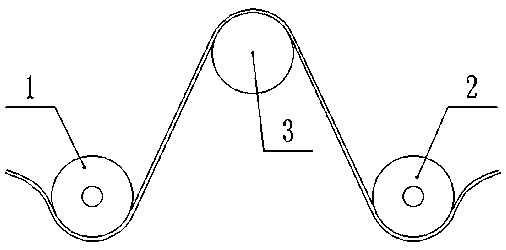

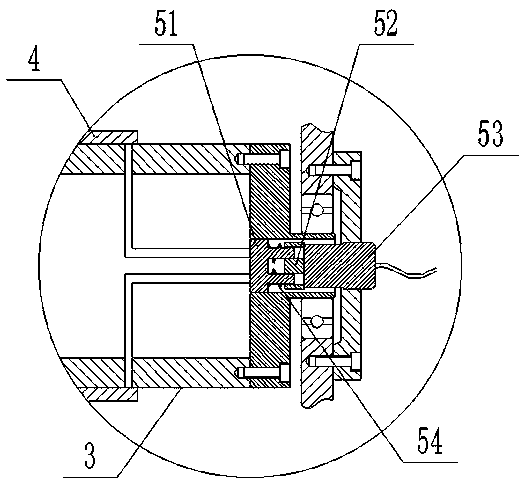

[0018] Such as Figure 1 to Figure 3 Shown: a tension sensor for a liquid ammonia mercerizing machine, the tension sensor is set between the driving wheel 1 and the driven wheel 2 in the liquid ammonia mercerizing machine, and the tension sensor includes: an idler wheel 3, a strain gauge 4 and a signal connector 5 The idler 3 is arranged between the driving wheel 1 and the driven wheel 2, and the two ends of the idler 3 are connected with the support of the liquid ammonia mercerizing machine through bearings, the idler 3 is a hollow tubular structure, and the surface of the idler 3 is fixed with A plurality of strain gauges 4, the plurality of strain gauges 4 are electrically connected to the signal connector 5, and the signal connector 5 is arranged at one end of the idler wheel 3;

[0019] The signal connector 5 includes: a fixed block 51, an intermediate connecting block 52 and a lead terminal 53; the fixed block 51, the intermediate connecting block 52 and the lead termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com