A kind of water-based insulating varnish for electronic transformer and its preparation method and application

A technology for electronic transformers and insulating varnishes, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of water-based paints that cannot be soldered twice, increase production costs, increase production processes, etc., and achieve excellent mechanical and electrical properties, Energy saving and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

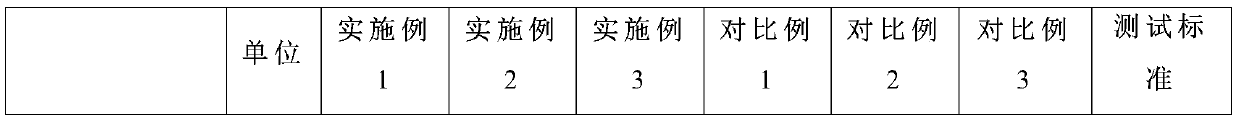

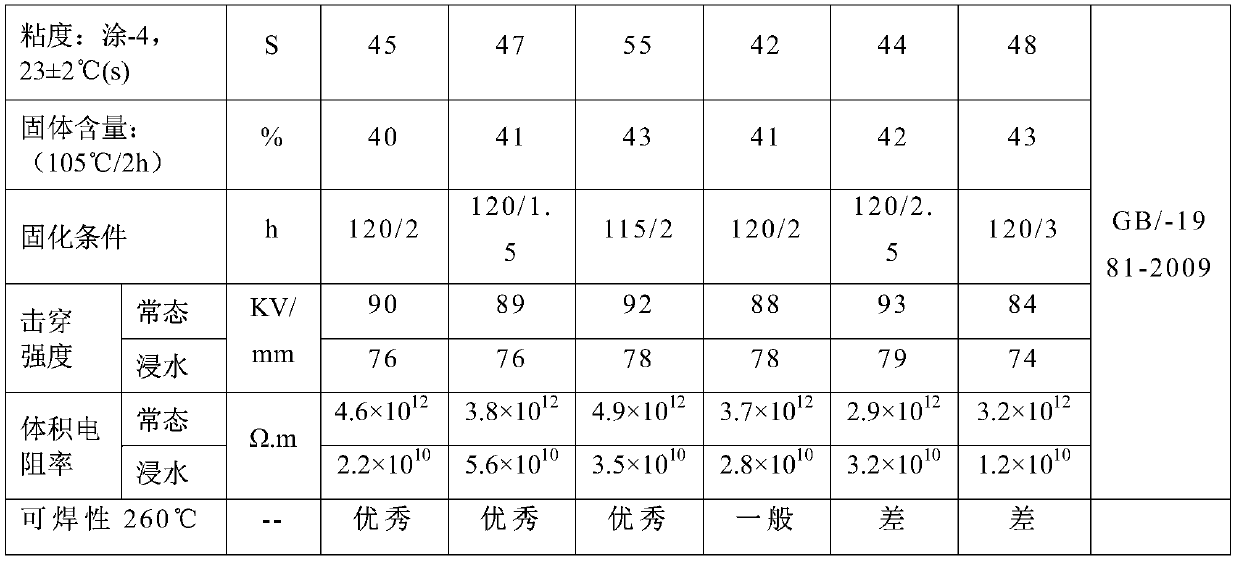

Examples

Embodiment 1

[0029] This embodiment provides a water-based insulating varnish for electronic transformers, the raw materials of which include glycerol 100g, neopentyl glycol 40g, phthalic anhydride 265g, trimellitic anhydride 50g, 1,6-hexamethylene diisocyanate 35g, 2,2 - 28 g of dimethylol propionic acid, 15 g of triethanolamine, 40 g of propylene glycol methyl ether, 55 g of melamine formaldehyde resin, and 200 g of water.

[0030] The preparation method is as follows: in a three-necked flask, add glycerol, neopentyl glycol, phthalic anhydride, trimellitic anhydride, control the temperature at 180-200°C, and undergo polycondensation until the acid value is less than or equal to 20mgKOH / g to obtain terminal Hydroxyl hyperbranched polyester, cool down to 80°C, add 1,6-hexamethylene diisocyanate dropwise, keep warm for 2 hours, add 2,2-dimethylol propionic acid, triethanolamine, propylene glycol methyl ether and water, keep warm for 2 hours, Lower the temperature to 50°C, add a water-based ...

Embodiment 2

[0032] This embodiment provides a water-based insulating varnish for electronic transformers, the raw materials of which include glycerol 105g, neopentyl glycol 40g, phthalic anhydride 296g, trimellitic anhydride 55g, 1,6-hexamethylene diisocyanate 35g, 2,2 - 30 g of dimethylol propionic acid, 15 g of triethanolamine, 40 g of propylene glycol methyl ether, 60 g of melamine formaldehyde resin, and 230 g of water.

[0033] Its preparation method is the same as Example 1.

Embodiment 3

[0035] This embodiment provides a water-based insulating varnish for electronic transformers, the raw materials of which include 100 g of glycerol, 45 g of neopentyl glycol, 265 g of phthalic anhydride, 50 g of trimellitic anhydride, 52 g of diphenylmethane diisocyanate, 2,2- Dimethylol propionic acid 28g, triethanolamine 20g, propylene glycol methyl ether 50g, melamine formaldehyde resin 55g, water 210g.

[0036] Its preparation method is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com