Vacuum stone provided with patterns and preparation technology

A preparation process and technology of vacuum stone, which is applied in the field of vacuum stone, can solve the problems of reducing the strength of synthetic stone and difficulty in improving the strength of synthetic stone, and achieve the effects of small usage, convenient mixing and processing, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

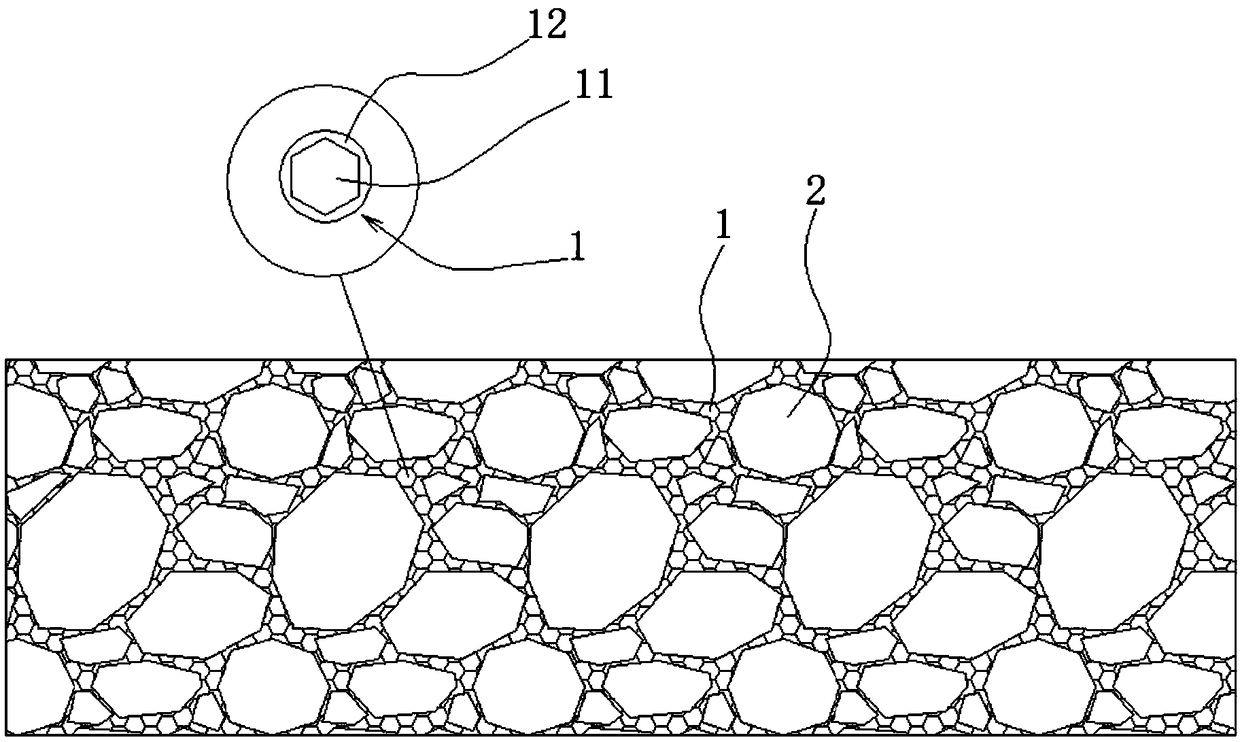

[0019] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings. The following description is merely exemplary in nature and is not intended to limit the application or uses of the present disclosure. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

[0020] The vacuum stone of the present invention is a brand-new plate material, which includes granular aggregates of different particle sizes and filling unit bodies with reference volumes, and the filling unit bodies are made of fine-grained solid particle fillers and liquid fillers, so The surface of the solid particle filler has a flexible liquid-filled film formed by filling the liquid filler, the particle aggregates of each particle size are filled and bonded to each other, and the gaps between the partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com