Tungsten carbide hard face abrasion-resistant bearing and preparation method thereof

A wear-resistant bearing, tungsten carbide technology, applied in metal processing equipment, transportation and packaging, coating, etc., can solve the problems of wear failure, high friction coefficient, etc., to change the surface friction coefficient, control friction and wear performance, improve friction and wear performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present application also provides a preparation method of the tungsten carbide hard-faced wear-resistant bearing, comprising the following steps:

[0037] Mix 20% to 55% of pure nickel powder or nickel-based alloy powder, 2.5% to 15% of self-lubricating component powder, and 30% to 77.5% of tungsten carbide particles according to volume percentage to obtain a mixed powder; the self-lubricating The component is a composite material of nickel-coated molybdenum disulfide or a composite material of nickel-coated graphite;

[0038] The mixed powder is molded on the cemented carbide to obtain a tungsten carbide hard surface wear-resistant bearing.

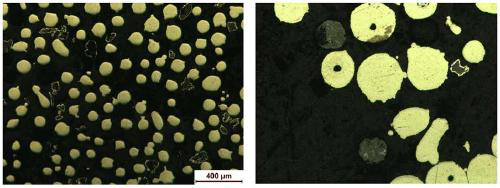

[0039] According to the present invention, pure nickel powder or nickel-based alloy powder, self-lubricating component powder and tungsten carbide particles are mixed according to the volume percentage; among the above-mentioned components, the particle size of self-lubricating component powder is 30-180 μm, and in specific im...

Embodiment 1

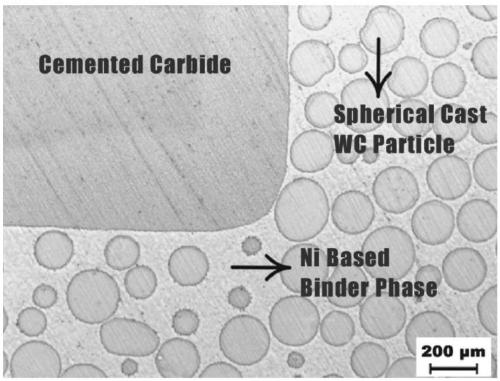

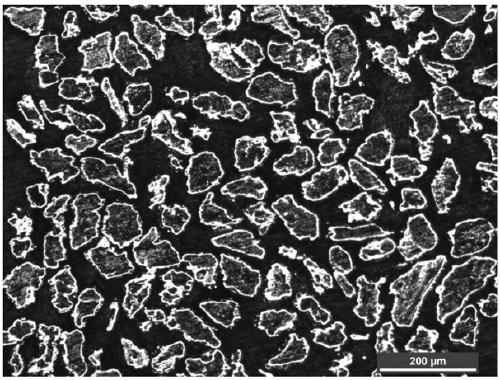

[0044] Ni-(4-20)Cr-(1-10)Si-( 0.5-5) B nickel-based alloy powder and spherical cast tungsten carbide with a particle diameter of 100-150 μm and a volume fraction of 40% are mixed to obtain a mixed powder. The above-mentioned mixed powder is surfacing welded on the cemented carbide through PTA to obtain a tungsten carbide hard-faced wear-resistant bearing. The hard-faced wear-resistant layer obtained by mixing the powder according to this ratio is defined as HF-01.

Embodiment 2

[0046] Ni-(4-20)Cr-(1-10)Si-( 0.5-5) B nickel-based alloy powder and spherical cast tungsten carbide with a particle diameter of 100-150 μm and a volume fraction of 40% are mixed to obtain a mixed powder. The above mixed powder is surfacing welded on the cemented carbide through PTA to obtain a tungsten carbide hard-faced wear-resistant bearing. The hard-faced wear-resistant layer obtained by mixing the powder according to this ratio is defined as HF-02.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com