A robot support board

A support plate and robot technology, applied in the direction of turbines, mechanical equipment, engine components, etc., can solve the problems of complex aluminum alloys, low alloy hardness, and lack of precision, so as to facilitate subsequent processing, enhance corrosion resistance, and increase load bearing effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

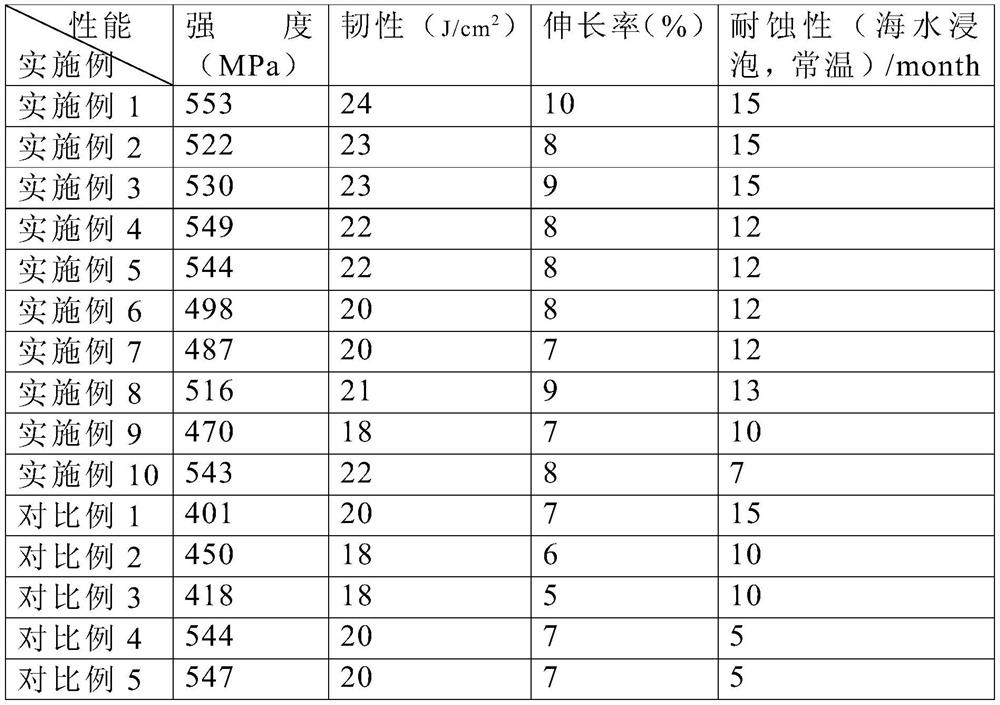

Examples

Embodiment 1

[0031] Ingredients: Weigh according to the material of the support plate. The support plate includes a carbon skeleton from the inside to the outside, and aluminum alloy coated on the outside of the carbon skeleton. The aluminum alloy is made of the following raw materials in mass percentage: Si: 0.09%, Mn: 0.06 %, Zn: 0.02%, B: 0.1%, O: 0.03%, the balance is Al and impurities, and Si, Mn, Zn, and B are respectively subjected to yeast culture to form yeast silicon, yeast manganese, yeast zinc, and yeast boron. The carbon skeleton is an ordered porous carbon skeleton, the pore diameter is 0.3mm, and the pores of the carbon skeleton are connected inside the skeleton;

[0032] Pretreatment: crush Al into powder, and mix it with yeast silicon, yeast manganese, yeast zinc, and yeast boron to form a mixed powder, and then fill the mixed powder into the interconnected pores of the carbon skeleton and completely cover the carbon skeleton;

[0033] Molding: Send the carbon skeleton coa...

Embodiment 2

[0036] Ingredients: Weigh according to the material of the support plate. The support plate includes the carbon skeleton from the inside to the outside, and the aluminum alloy coated on the outside of the carbon skeleton. The aluminum alloy is made of the following raw materials in mass percentage: Si: 0.06%, Mn: 0.04 %, Zn: 0.01%, B: 0.05%, O: 0.02%, the balance is Al and impurities, and Si, Mn, Zn, and B are respectively subjected to yeast culture to form yeast silicon, yeast manganese, yeast zinc, and yeast boron. The carbon skeleton is an ordered porous carbon skeleton, the pore diameter is 0.1mm, and the pores of the carbon skeleton are connected inside the skeleton;

[0037] Pretreatment: crush Al into powder, and mix it with yeast silicon, yeast manganese, yeast zinc, and yeast boron to form a mixed powder, and then fill the mixed powder into the interconnected pores of the carbon skeleton and completely cover the carbon skeleton;

[0038] Molding: Send the carbon skele...

Embodiment 3

[0041] Ingredients: weighed according to the material of the support plate. The support plate includes a carbon skeleton from the inside to the outside, and aluminum alloy coated on the outside of the carbon skeleton. The aluminum alloy is made of the following raw materials in mass percentage: Si: 0.12%, Mn: 0.08 %, Zn: 0.03%, B: 0.15%, O: 0.04%, the balance is Al and impurities, and Si, Mn, Zn, and B are respectively subjected to yeast culture to form yeast silicon, yeast manganese, yeast zinc, and yeast boron. The carbon skeleton is an ordered porous carbon skeleton, the pore diameter is 0.5 mm, and the pores of the carbon skeleton are connected inside the skeleton;

[0042] Pretreatment: crush Al into powder, and mix it with yeast silicon, yeast manganese, yeast zinc, and yeast boron to form a mixed powder, and then fill the mixed powder into the interconnected pores of the carbon skeleton and completely cover the carbon skeleton;

[0043] Molding: Send the carbon skeleton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com