High-performance through hole foamed aluminum material and preparation process thereof

A preparation process, foamed aluminum technology, applied in the field of new metal materials and structural metal materials, to achieve good electromagnetic shielding performance, overcome the complexity of the process, and improve the effect of damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for a transitional filled spherical material, mainly comprising: weighing 65%-80% gypsum, 15%-20% bauxite, 5%-10% calcium carbonate, 5%-10% Nano-based bentonite, fully mixed in a mixer, granulated by a disc granulator, and 15%-25% water-based glue is added in a uniform spraying manner to make a foamed aluminum transition with a diameter of 2-12mm Permanent filled spheres, drying the filled spheres at 80-120°C for 2-3 hours until the moisture is completely removed, and sieving through a multi-stage rotary sieve to obtain transitional filled sphere materials with required particle sizes.

Embodiment 2

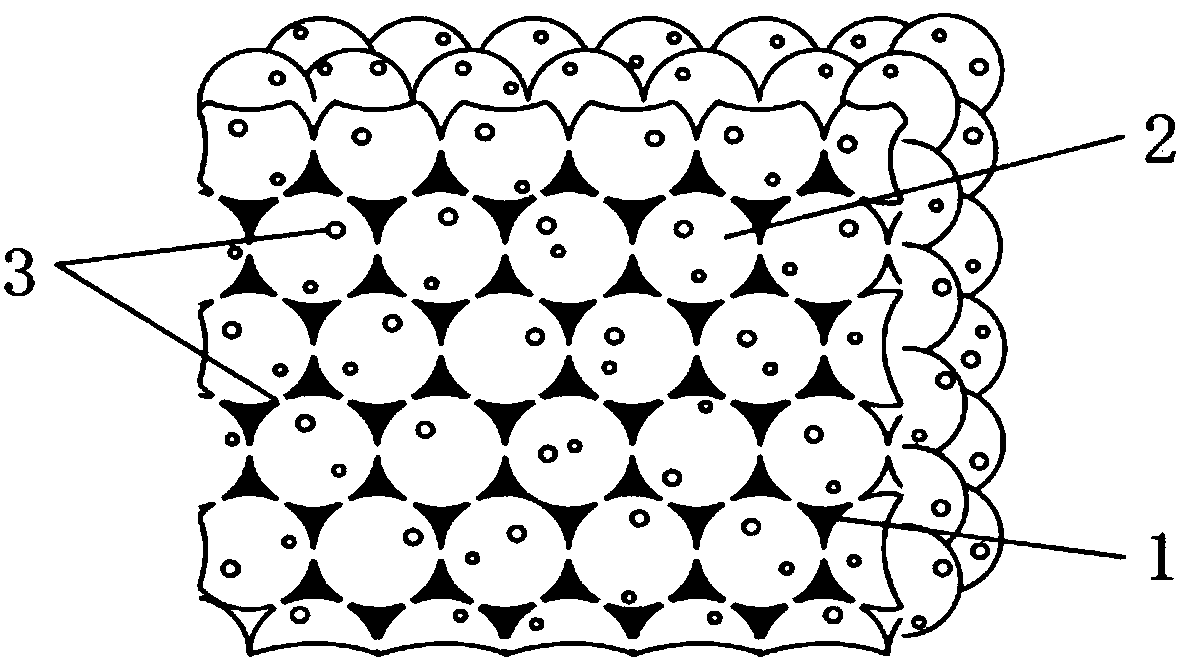

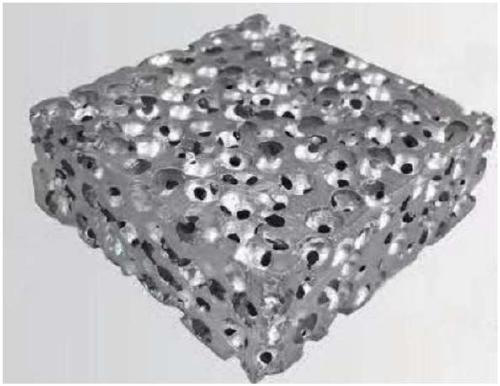

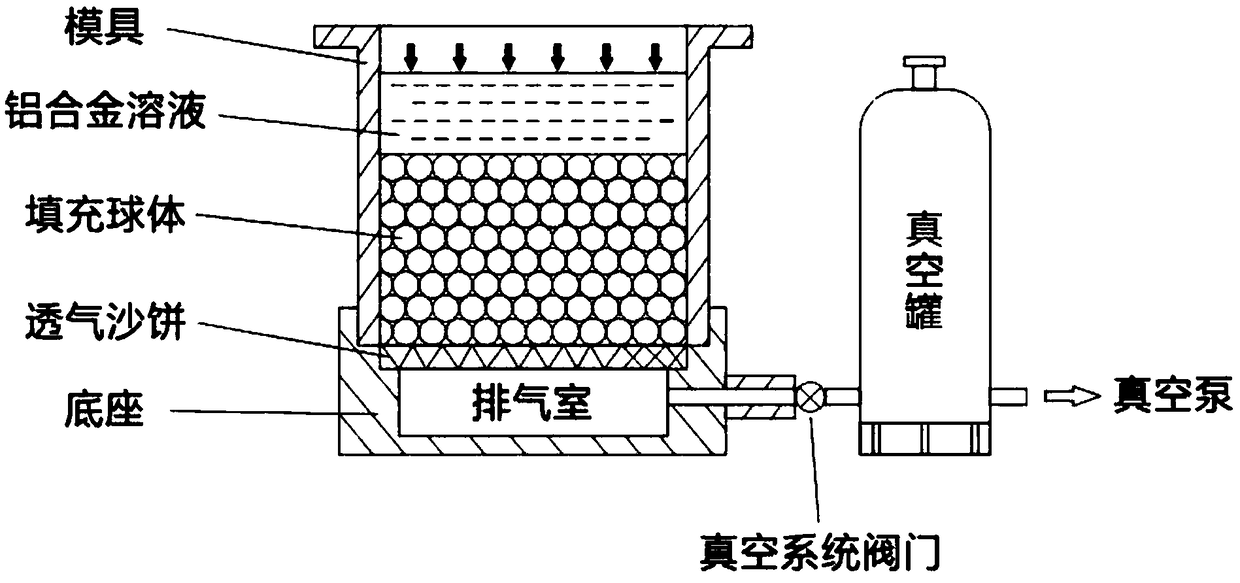

[0031] A preparation process of a high-performance through-hole foamed aluminum material mainly includes the following steps:

[0032]a, by weight, 65%-80% gypsum, 15%-20% bauxite, 5%-10% calcium carbonate, 5%-10% nano-bentonite powder are fully mixed in the mixer Mix evenly, configure 15%-25% water-based glue, and use a disc granulator for granulation; control the diameter of the transitional filling sphere according to the performance requirements of the through-hole foam aluminum material: by controlling the addition of mixed powder and spray glue The speed of the liquid is made into a foamed aluminum transitional filled sphere with a diameter of 2-12mm;

[0033] b. Dry the transitional filled spheres made in the above a. in an oven at 80-120°C for 2-3 hours until the water is completely removed, and sieve through a multi-stage rotary sieve to obtain the required transition particle size. sexually filled sphere;

[0034] c. According to the different performance requireme...

Embodiment 3

[0050] The transitional filling sphere material in Example 2 was replaced by the components of serial numbers 1-8 to prepare aluminum foam materials, and the experimental results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com