Water/oil-in-powder type anti-aging composition as well as preparation method and application thereof

An anti-aging, water-in-powder technology, which is applied in pharmaceutical formulas, cosmetic preparations, dressing preparations, etc., can solve the problems of mediocre anti-aging effects and rare anti-aging products, and achieve a novel experience, maintain and eliminate wrinkles, Excellent anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

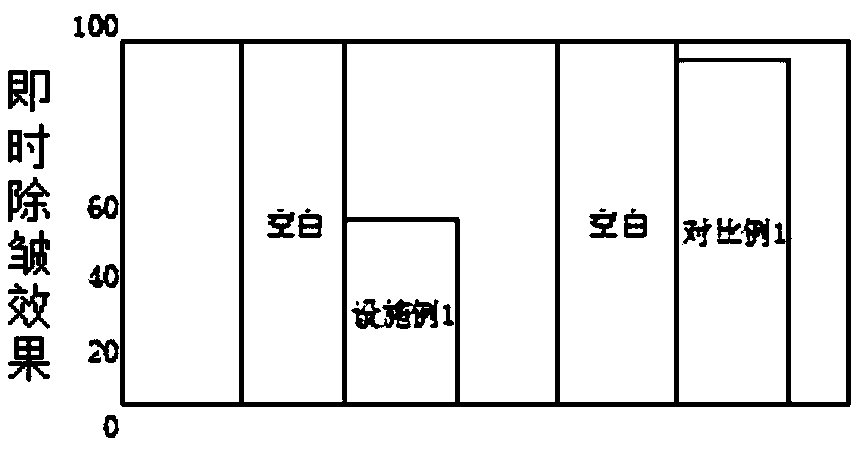

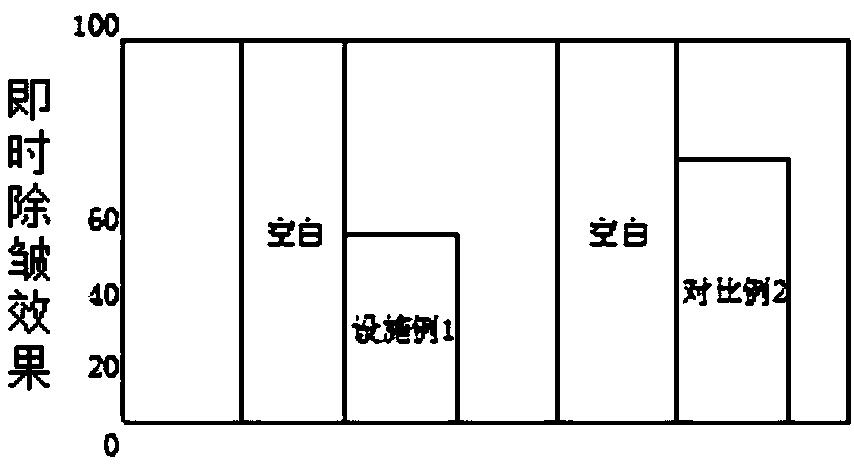

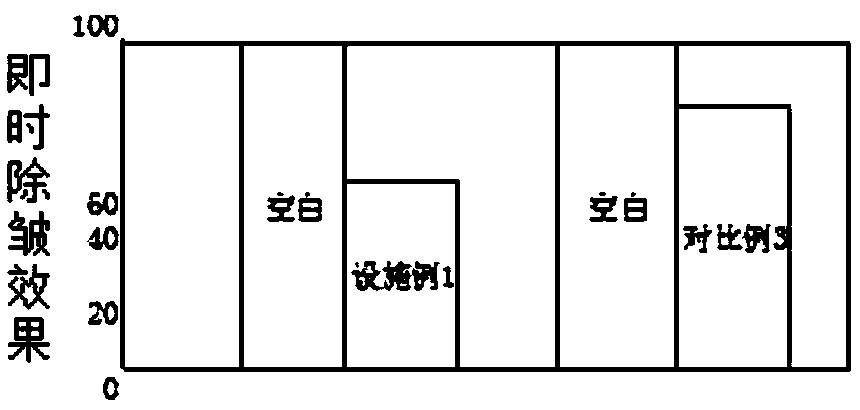

Examples

Embodiment 1

[0026] The formulas of embodiment 1, comparative example 1-comparative example 3 are shown in table 1.

[0027] The formula of table 1 embodiment 1, comparative example 1-comparative example 3:

[0028]

[0029] Table 1

[0030] Preparation method: S1. Heat water, humectant, emulsifier, and thickener to dissolve, stir evenly, keep warm to obtain a water phase; S2. stir oil evenly to obtain an oil phase; S3. prepare the water phase prepared in step S1, The oil phase prepared in step S2 is sequentially added into the emulsification pot, homogenized, stirred evenly, heat-preserved and defoamed, and after cooling down, anti-wrinkle active substances and preservatives are added, and stirred evenly. S4. Add the powder raw materials into the powder mixer, stir evenly for the first time, slowly add S3, and stir for the second time until the coating is complete.

Embodiment 2

[0032] A powder-in-water-in-oil type anti-aging composition, which consists of the following components in parts by weight: 5 parts of polydimethylsiloxane silylated silica and polymethyl methacrylate; 5 parts of methyl siloxane; 2 parts of polyglyceryl-10 myristate; 0.5 parts of sodium carbomer; 3 parts of glutaminyl ethyl indole with concanavalia fruit extract; 1,2-pentanedi 3 parts of alcohol; 0.5 parts of caprylyl hydroxamic acid, and add water to the balance to 100 parts;

[0033] The preparation method is the same as in Example 1.

Embodiment 3

[0035] A powder-in-water-in-oil type anti-aging composition, which is composed of the following components in parts by weight: 10 parts of polydimethylsiloxane silica silylate; 10 parts of cyclopentasiloxane ; Polyglyceryl-10 Stearate 10 parts; Polyacrylate Crosspolymer-6 2 parts; Glutaminyl Ethyl Indole with Conavalin Fruit Extract 10 parts; Glycerin 10 parts; Caprylyl Hydroxime 1 part of acid, and add water to the balance to 100 parts.

[0036] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com