Extremely-low-temperature self-heating device of aluminum-based self-heating agent and application of extreme-low-temperature self-heating device

A self-heating technology based on a heating agent, applied in heating devices, heat exchange materials, chemical instruments and methods, etc., can solve problems such as difficult start-up, slow heat release, and affecting the heating effect of aluminum-based self-heating agents, and achieve Avoid the effect of the explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A self-heating device for an aluminum-based self-heating agent at extremely low temperatures, including antifreeze lye, a low-temperature heating agent, and an aluminum-based heating agent;

[0045] In this embodiment, the antifreeze lye is 5 mL in total, containing the following solutes in mass percent: 15% sodium chloride, 5% magnesium chloride, and 10% sodium hydroxide.

[0046] The low-temperature heating agent is 5 g in total, containing the following components in mass proportion: 50% of aluminum powder, 10% of iron powder, 10% of magnesium powder, 10% of carbon powder, 10% of calcium oxide and 10% of sodium carbonate, the particle diameter of aluminum powder 200-300μm.

[0047] The aluminum-based heating agent is 40g in total, and the mass ratio of each component is: 40% of aluminum powder, 30% of quicklime, 20% of sodium carbonate, and 10% of zeolite, wherein the particle size of the aluminum powder is between 300-600 μm.

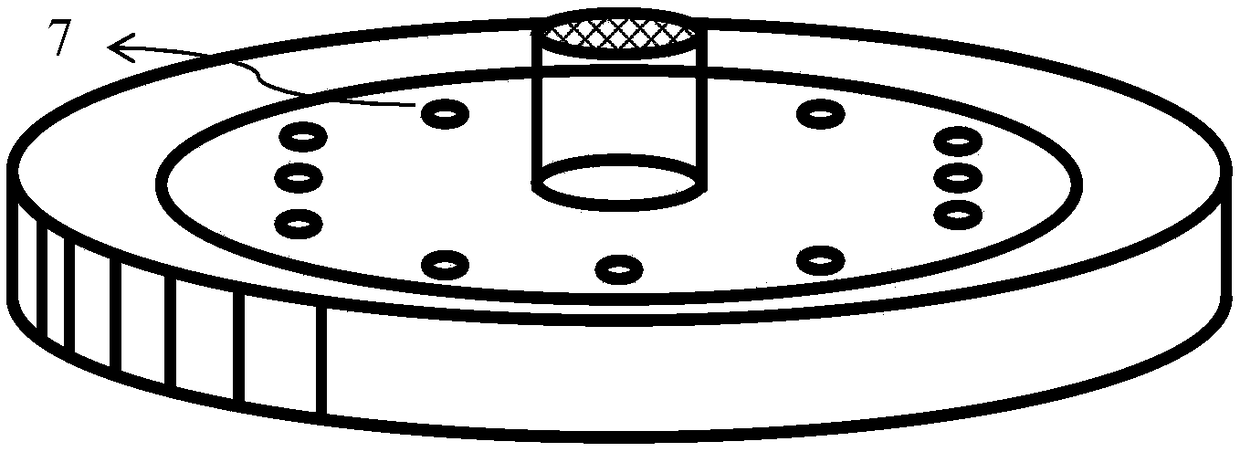

[0048] see figure 1 and figure 2 ,...

Embodiment 2

[0055] A self-heating device for an aluminum-based self-heating agent at extremely low temperatures, including antifreeze lye, a low-temperature heating agent, and an aluminum-based heating agent;

[0056] In this embodiment, the antifreeze lye is 5 mL in total, containing the following solutes in mass percent: 10% sodium chloride, 5% magnesium chloride, and 5% potassium hydroxide.

[0057] The low-temperature heating agent is 5g in total, and contains the following components in mass proportion: 50% of aluminum powder, 10% of iron powder, 5% of magnesium powder, 5% of carbon powder, and 30% of calcium oxide. The particle size of the aluminum powder is 200-300 μm.

[0058] The aluminum-based heating agent is 40g in total, and its ingredients are: 40% of aluminum powder, 20% of quicklime, 10% of sodium carbonate, and 10% of zeolite, wherein the particle size of the aluminum powder is between 300-600 μm.

[0059] The structure of this device is basically the same as that of Emb...

Embodiment 3

[0061] A self-heating device for an aluminum-based self-heating agent at extremely low temperatures, including antifreeze lye, a low-temperature heating agent, and an aluminum-based heating agent;

[0062] In this embodiment, the antifreeze lye is 5 mL in total, containing the following solutes in mass percent: 10% sodium chloride, 5% magnesium chloride, and 10% sodium hydroxide.

[0063] The low-temperature heating agent is 5 g in total, and contains the following components in mass proportion: 50% of aluminum powder, 10% of iron powder, 5% of magnesium powder, 15% of carbon powder, and 20% of calcium oxide. The particle size of the aluminum powder is 200-300 μm.

[0064] The aluminum-based heating agent is 40g in total, and its ingredients are: 40% of aluminum powder, 30% of quicklime, 20% of sodium carbonate, and 10% of zeolite, wherein the particle size of the aluminum powder is between 300-600 μm.

[0065] The structure of this device is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com