Deep scarification weeding machine monomer and deep scarification weeding machine

A weeding machine and subsoiling technology, which is applied in the field of subsoiling weeding machines and subsoiling weeding machines, which can solve the problem of unevenness of the ridge surface, poor adhesion to the ridge surface, and reduce the depth of the weeding roller into the ridge surface, etc. problem, to achieve the effect of guaranteeing the depth requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The forward and backward directions of the present invention are relative to the forward and backward directions when the subsoiler weeder works. The left and right directions are the left and right sides of the forward direction, and the inner and outer directions are the direction of the ridge surface relative to the furrow, wherein the ridge surface is inside the two furrows.

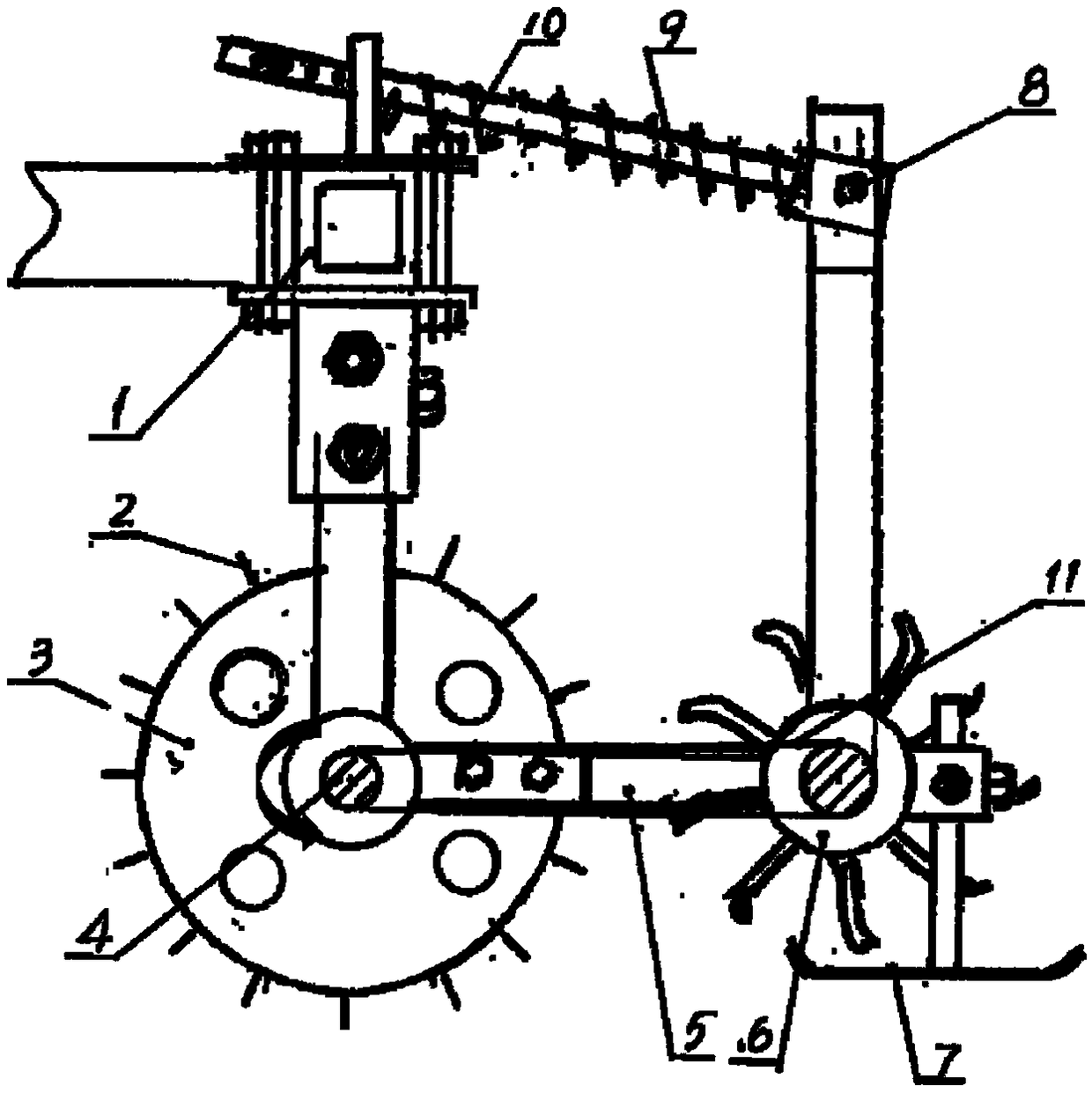

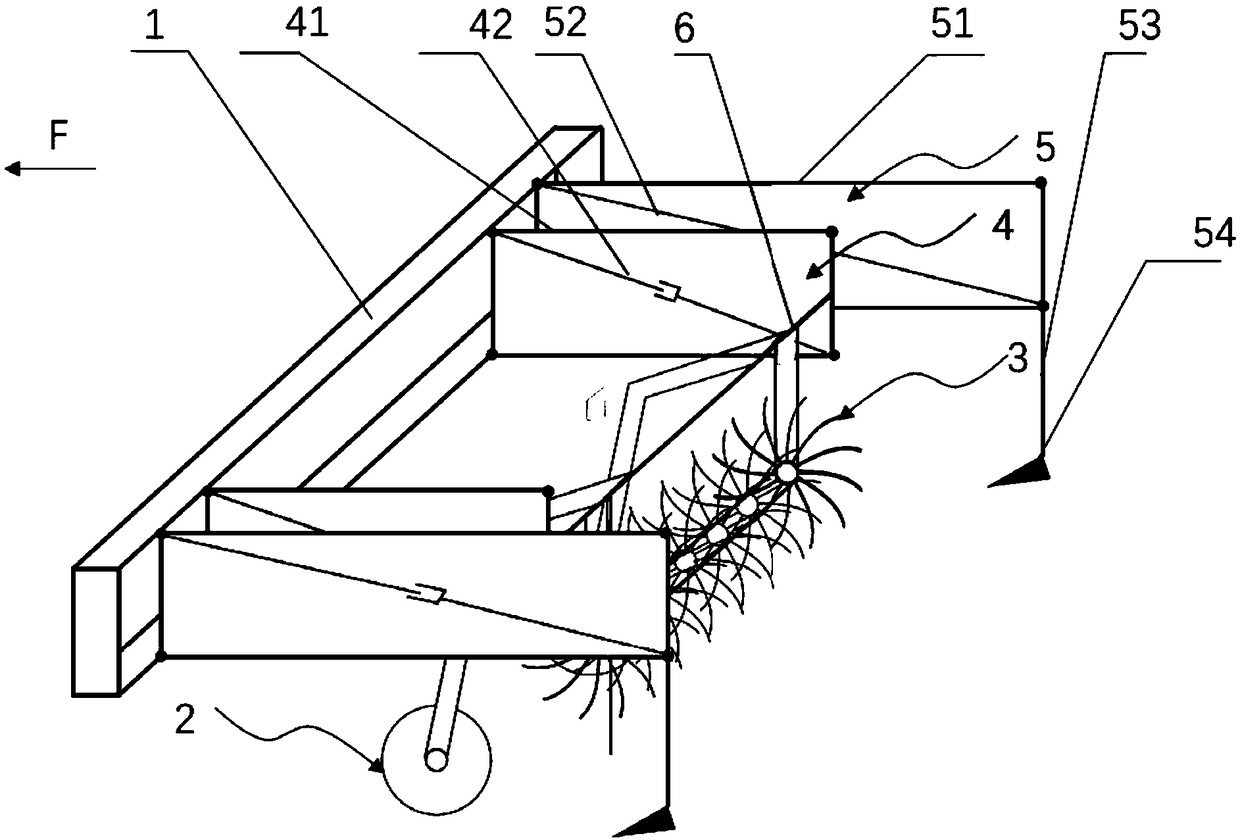

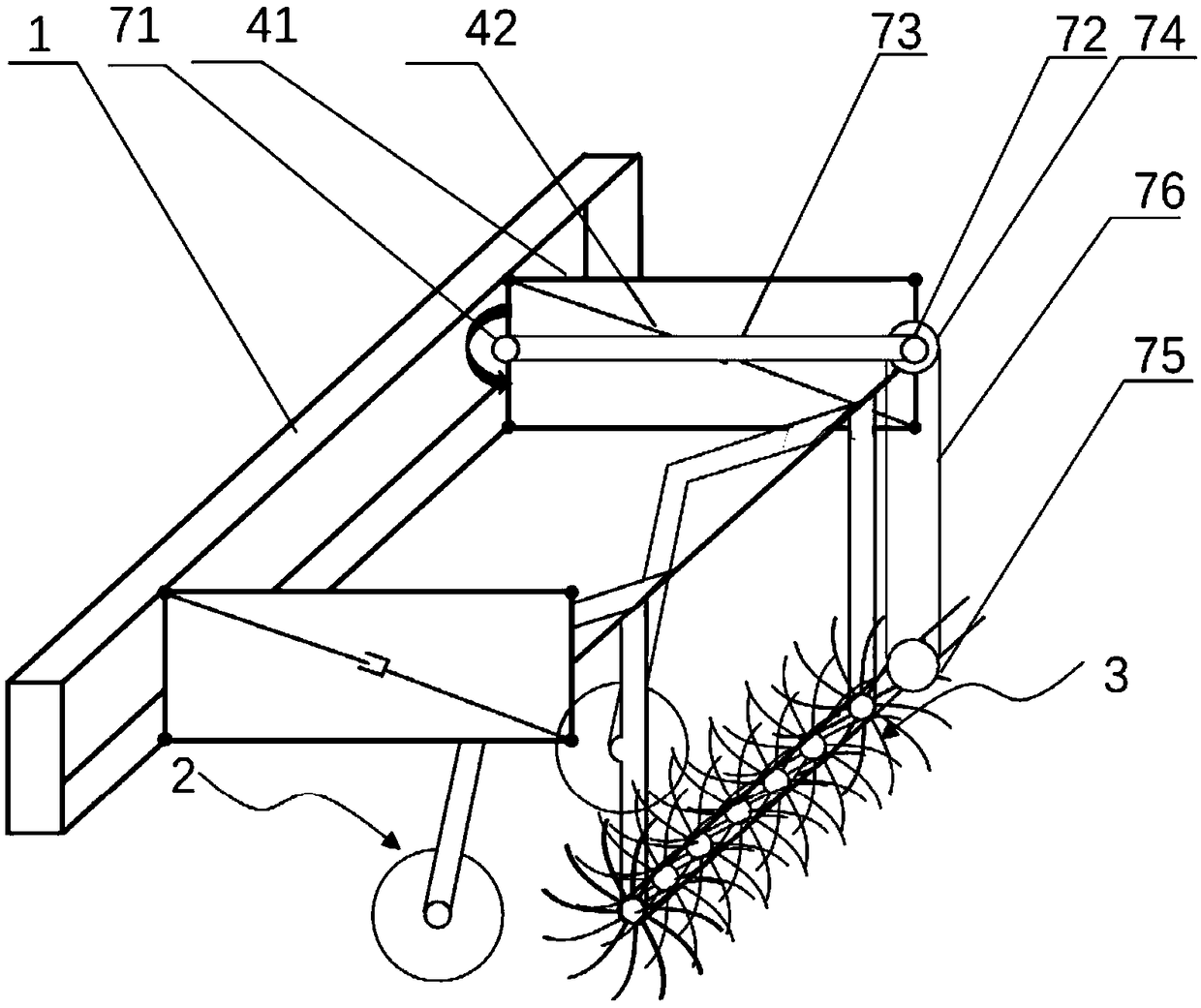

[0015] Such as Figure 2-3 A single subsoiling weeder is shown, including a frame 1, a depth-gauge wheel assembly 2, a weeding roller assembly 3 and a weeding roller assembly frame 4;

[0016] Among them, the frame is connected to the agricultural vehicle, and the agricultural vehicle pulls the subsoil weeder unit along the F direction in 2;

[0017] The weeding roller assembly frame 4 comprises the left and right weeding parallelogram connecting rods 41 positioned at the left and right sides of the frame. The two ends of the weeding front rod and the weeding rear rod are pivotally connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com