Pneumatic conveying no-till subsoiling fertilization seeder

A pneumatic conveying and seeding machine technology, applied in the direction of agricultural machinery and implements, shovels, plows, etc., can solve the problems of seed drilling, affecting fertilizer efficiency, and destroying the soil ecological environment, so as to reduce resistance, prevent congestion, and facilitate transportation and location The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

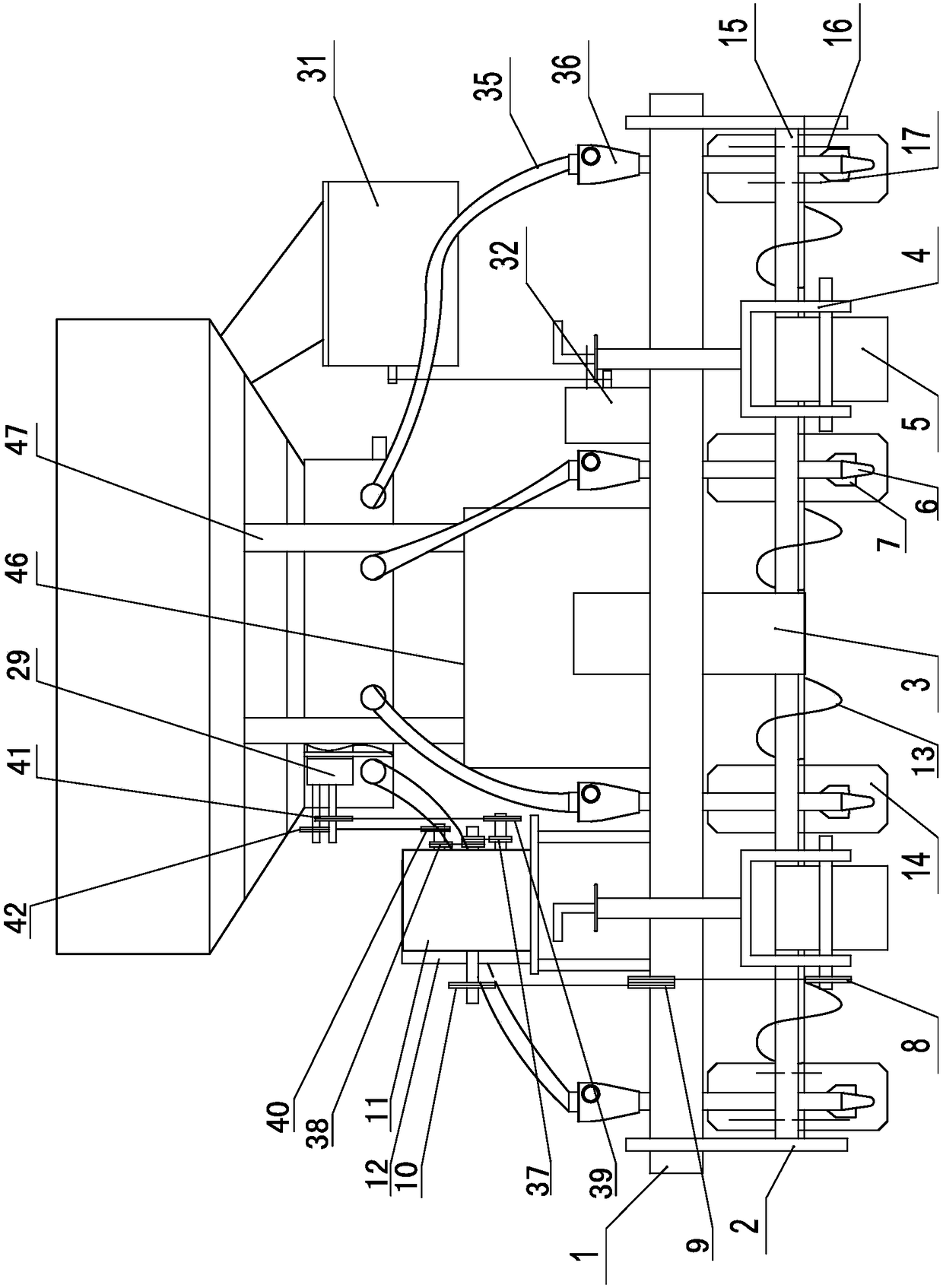

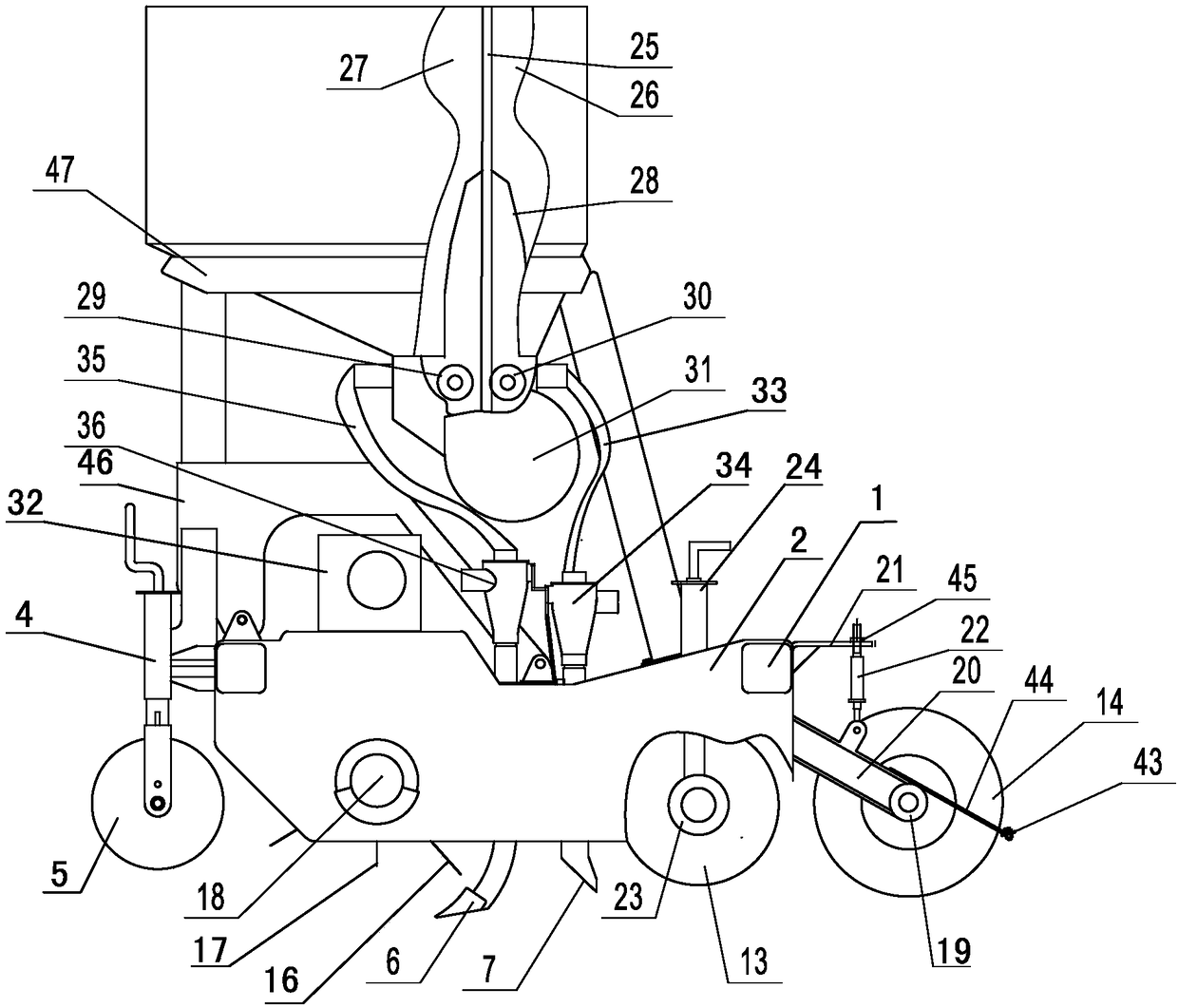

[0020] exist Figure 1-2 In the example shown, the main gearbox 3 is mounted on the frame 1 . In the direction of travel:

[0021] The depth-limiting wheel 5 is mounted on the front end of the frame 1 via the depth-limiting wheel bracket 4 .

[0022] The seedling belt cleaner is installed below the inner side of the front end of the frame side plate 2, including a knife shaft 15 and a group of long straight knives 16 and a group of short straight knives 17 arranged according to two spiral lines. The shaft bearing seat 18 is installed on the two opposite frame side plates 2 , and the middle part of the cutter shaft 15 is drivingly connected with the output end of the main gearbox 3 .

[0023] The pressing wheel 14 is located at the rear and bottom of the frame 1, and is installed at the rear end of the pressing wheel bracket 20 through the pressing wheel bearing seat 19. The front end of the pressing wheel bracket 20 is hinged with the frame 1, and the pressing wheel limiter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com