Multilayer substrate integrated waveguide third-order filter power divider

A substrate-integrated waveguide and power divider technology, applied in waveguide devices, electrical components, connecting devices, etc., can solve the problems of increased circuit area, worsened insertion loss, and poor filtering performance, achieving high space utilization, Ease of processing and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

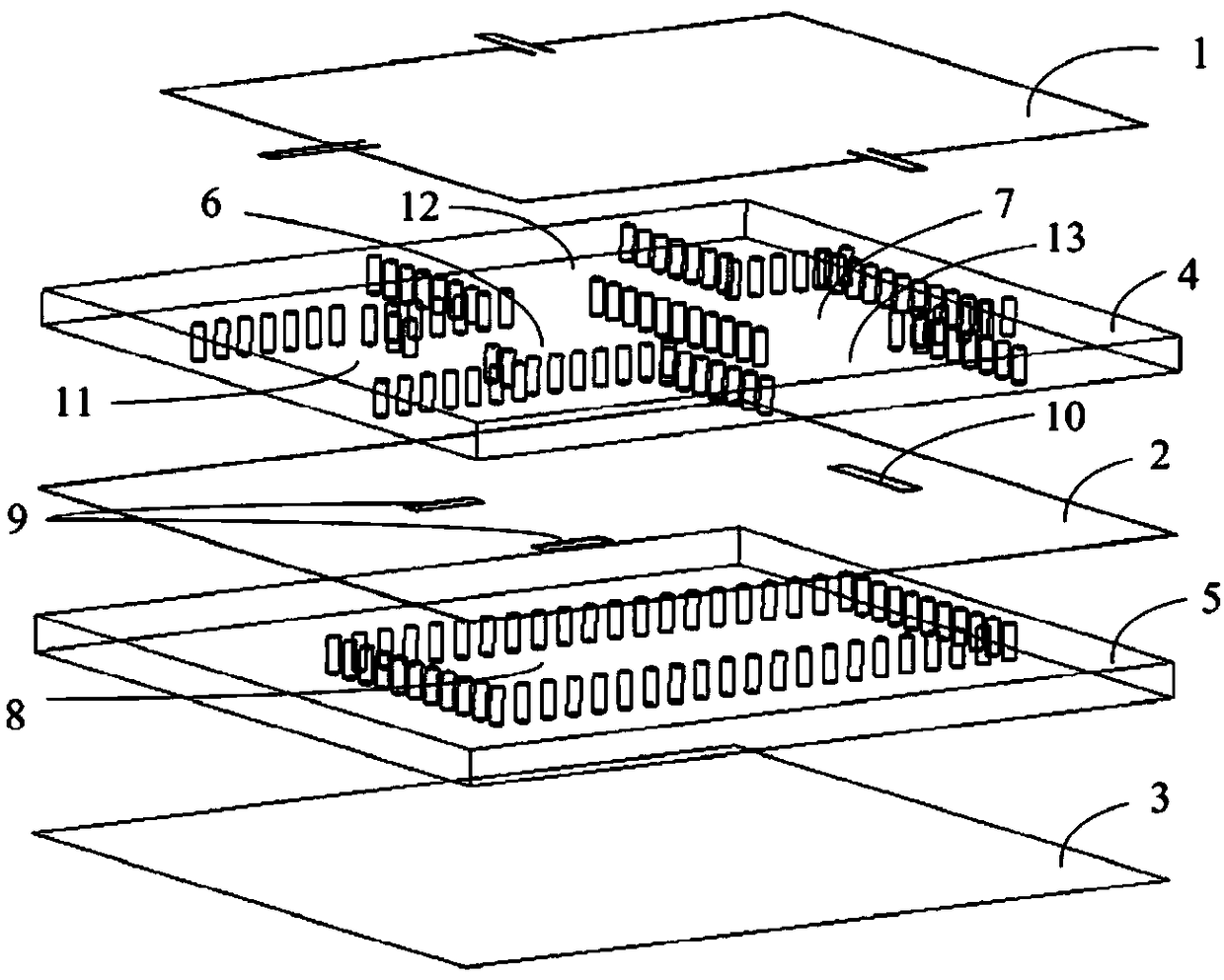

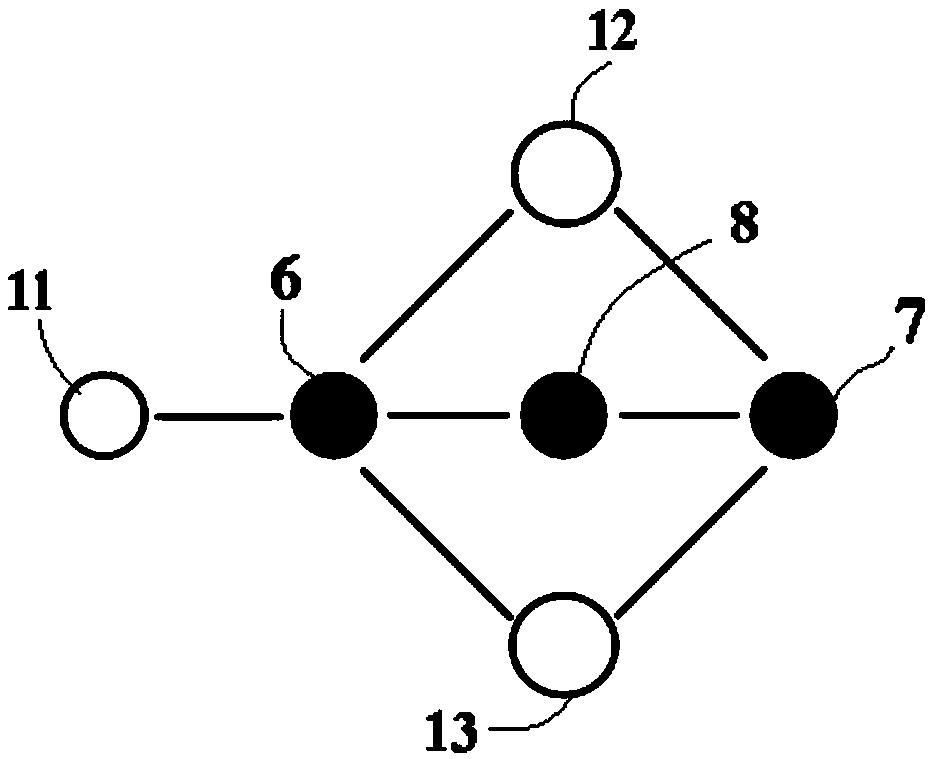

[0036] Please refer to figure 1 , a multi-layer substrate integrated waveguide third-order filter power divider, including a first metal layer 1, a second metal layer 2 and a third metal layer 3 stacked, the first metal layer 1 and the second metal layer 2 A first dielectric substrate 4 is arranged between them, and a second dielectric substrate 5 is arranged between the second metal layer 2 and the third metal layer 3;

[0037] The first dielectric substrate 4 is provided with a first resonant cavity 6, a second resonant cavity 7, an input waveguide 11, a first output waveguide 12 and a second output waveguide 13;

[0038] The input waveguide 11 , the first output waveguide 12 and the second output waveguide 13 are converted from the substrate-integrated waveguide port of the first dielectric substrate 4 into the microstrip port output of the first metal layer 1 .

[0039] A third resonant cavity 8 is arranged on the second dielectric substrate 5;

[0040] The input wavegui...

Embodiment 2

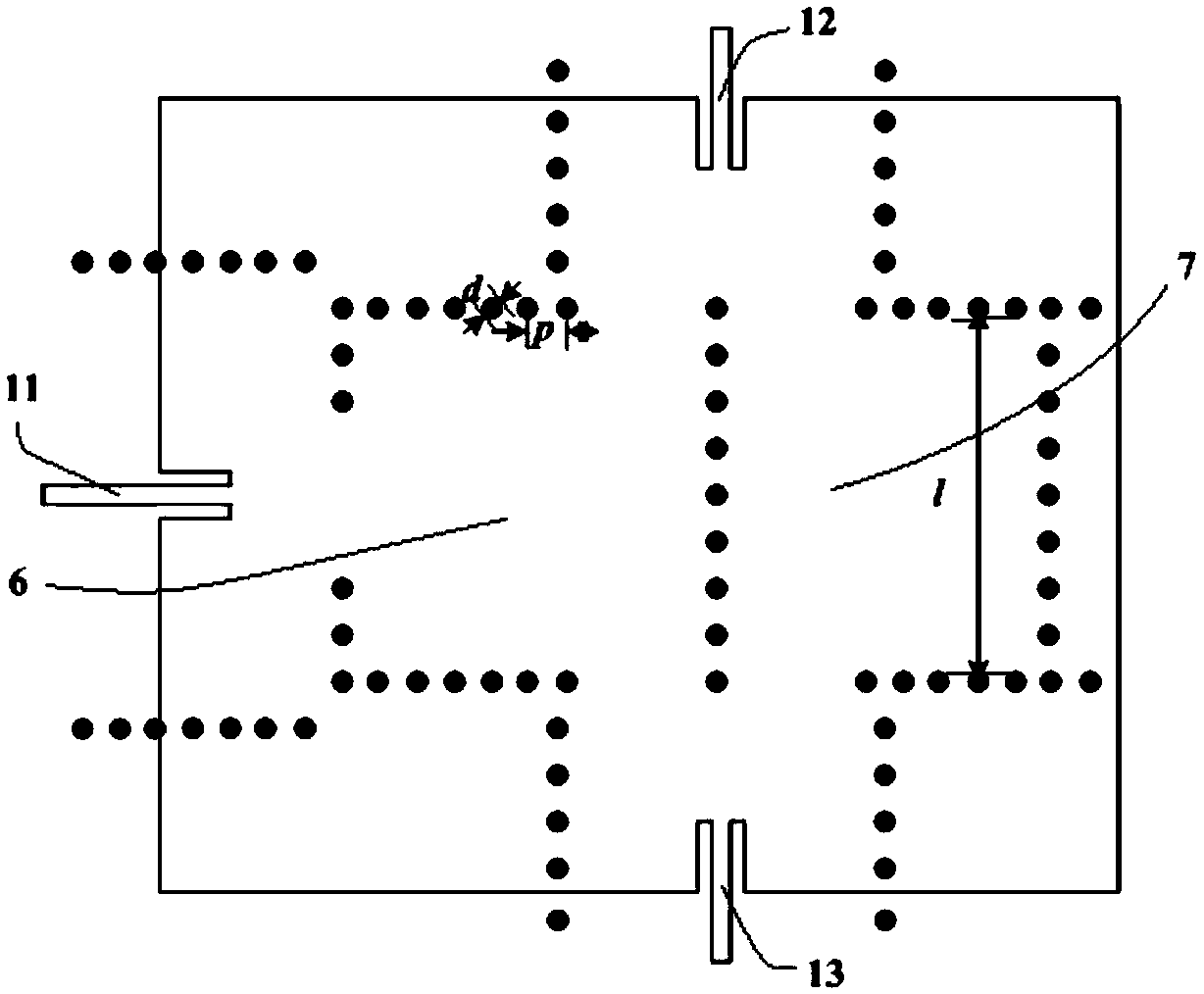

[0049] to combine figure 1 , please refer to Figure 3 ~ Figure 5 , the center frequency of the multi-order substrate integrated waveguide third-order filter power divider is controlled at 6.8GHz, the substrate material used in the first dielectric substrate 4 and the second dielectric substrate 5 is Rogers RO4350B, the dielectric constant is 3.48, and the thickness is 0.508 mm; the diameter d=0.7mm of all the metallized via holes on the first dielectric substrate and the second dielectric substrate, the pitch p=1.5mm; the width l=15mm of the first resonant cavity, the second resonant cavity and the third resonant cavity ;Length l of the first slot 9 1 =4.5mm, width w 1 =1.2mm; the length l of the second slot 10 2 =6.9mm, width w 2 = 1.2 mm.

[0050] Please refer to Figure 6 , it can be seen that the center frequency of the above multi-order substrate integrated waveguide third-order filter power divider is 6.77GHz, and the two output channels are equal in amplitude and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com