Lithium-sulfur battery positive electrode material and preparation method thereof

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low electrochemical performance, battery specific capacity, low cycle retention rate, etc., to achieve high cycle retention rate, Effect of inhibiting polysulfide ion shuttle and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

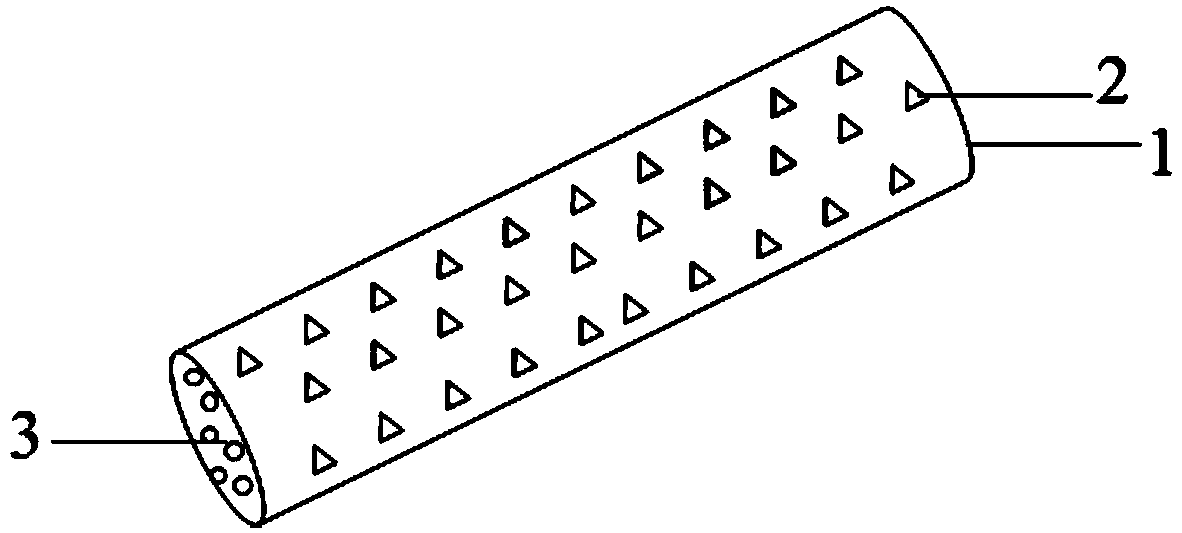

[0043] The lithium-sulfur battery cathode material includes a matrix layer, a polymer layer covering the matrix layer, and a core layer located in the matrix layer. like figure 1 As shown, 1 is the base layer, 2 is the polymer layer, and 3 is the core layer.

[0044] The matrix layer is halloysite, the polymer is one of polypyrrole (PPy), polyaniline (PANI) and poly-3,4-ethylenedioxythiophene (PEDOT), and the core layer is a sulfur elemental layer.

[0045] figure 2 It is a scanning electron microscope (SEM) picture of untreated halloysite. From the picture, it can be seen that halloysite has smooth outer walls and hollow channels.

Embodiment 2

[0047] Lithium-sulfur battery cathode material, the preparation method comprising:

[0048] (1) heat treatment after halloysite is extracted with acid, specifically:

[0049]Add 10g of natural halloysite solid powder to a solution consisting of 28ml of concentrated hydrochloric acid with a mass fraction of 38% and 7ml of deionized water, react at 70°C for 120min, then centrifuge, wash and filter to obtain a solid, and place it in an oven at 80°C Dry for 24 hours to obtain halloysite powder purified by acid leaching. Put the purified halloysite powder in a tube furnace under an argon atmosphere, keep it at 300°C for 3h, and heat up at a rate of 5°C / min. Heat-treated halloysite powder.

[0050] (2) Dispersing the halloysite processed in step (1) in a solvent, adding the polymer and oxidant to the solvent to obtain a semi-finished product after polymerization, specifically:

[0051] Add 0.1g of halloysite treated in step (1) into 90ml of deionized water, ultrasonicate at room t...

Embodiment 3

[0056] Lithium-sulfur battery cathode material, the preparation method comprising:

[0057] (1) heat treatment after halloysite is extracted with acid, specifically:

[0058] Add 10g of natural halloysite solid powder to a solution consisting of 28ml of concentrated hydrochloric acid with a mass fraction of 38% and 7ml of deionized water, react at 70°C for 120min, then centrifuge, wash and filter to obtain a solid, and place it in an oven at 80°C Dry for 24 hours to obtain halloysite powder purified by acid leaching. Put the purified halloysite powder in a tube furnace under an argon atmosphere, keep it at 300°C for 3h, and heat up at a rate of 5°C / min. Heat-treated halloysite powder.

[0059] (2) Dispersing the halloysite processed in step (1) in a solvent, adding the polymer and oxidant to the solvent to obtain a semi-finished product after polymerization, specifically:

[0060] Add 0.1 g of halloysite treated in step (1) into 90 ml of deionized water, sonicate at room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com