Styrene-butyl acrylate surface waterproof glue and preparation method thereof

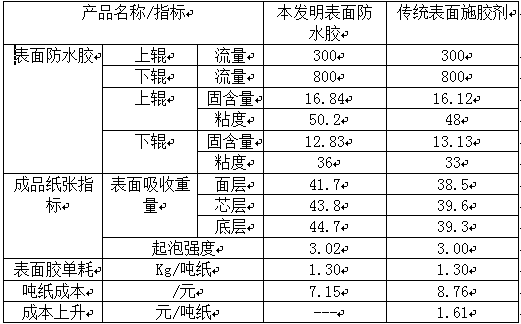

A technology of butyl acrylate and styrene, applied in the field of chemical raw material preparation, can solve the problems of environmental protection, loss of market, poor printability, poor paper strength, etc., and achieve the effects of significant economic and social benefits, bright ink, and lightening of color smearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Example: A styrene-butyl acrylate surface waterproof adhesive, which is composed of the following components in parts by weight: 100 parts of starch, 0.065 parts of medium temperature amylase, 12 parts of glacial acetic acid, 0.5 parts of ferrous sulfate, hydrogen peroxide 25 parts, 125 parts styrene, 50 parts butyl acrylate, 15 parts rosin, 3.5 parts Gemini emulsifier, 1.0 silicone defoamer, 675 parts deionized water.

[0025] The above-mentioned preparation method of styrene-butyl acrylate surface waterproof glue, its specific steps are as follows

[0026] A. Pump 125 parts of styrene and 50 parts of butyl acrylate into the titration vessel A, and stir at a speed of 80r / min. While stirring, slowly add 15 parts of rosin. After the rosin is completely melted, add 0.5 Parts of Gemini emulsifier and 50 parts of deionized water, continue to stir evenly, increase the speed to 150r / min 30 minutes before titration, until the titration is completed, titrant A is obtained;

[0027] B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com