High-temperature synthetic heat conducting oil

A heat-conducting oil and high-temperature technology, applied in the chemical industry, can solve problems such as low terphenyl yield, insufficient supply of terphenyl, complex hydrogenation process and equipment, etc., achieve simple process conditions, make up for insufficient raw material sources, and facilitate the reaction process The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 300g of biphenyl into the four-necked flask, heat and melt, add 15g of aluminosilicate catalyst after the biphenyl is melted, set the reaction temperature to 215°C, and when the reaction temperature is reached, start to pour the mixture into the reaction system at a rate of 1s / drop Cyclohexene was added dropwise. When cyclohexene was distilled off in the condensation reflux device connected with the four-necked flask, the dropwise addition of cyclohexene was stopped, and the reaction ended. The reaction solution is cooled, the catalyst is filtered, and transferred to a rectification kettle for rectification, the biphenyl and some light components in front are cut off, and the latter components are collected to obtain a cyclohexylbiphenyl composition. Gained product is carried out gas chromatographic analysis, and result is as follows table 1:

[0021] Table 1

[0022] components

[0023] Among them, polybiphenyls and partially hydrogenated polybiphenyls ...

Embodiment 2

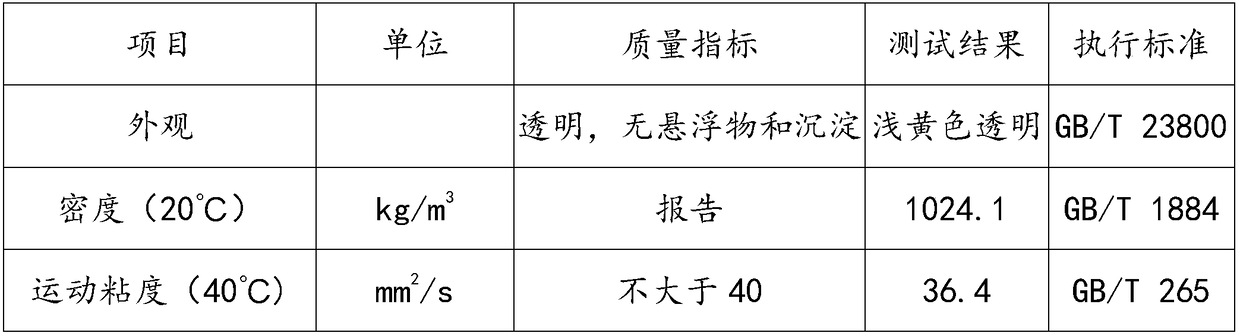

[0025] The cyclohexylbiphenyl composition was obtained according to the method in Example 1, and its performance test and thermal stability test were carried out according to the standard of heat transfer oil. The test results are shown in Table 2 below:

[0026] Table 2

[0027]

[0028]

Embodiment 3

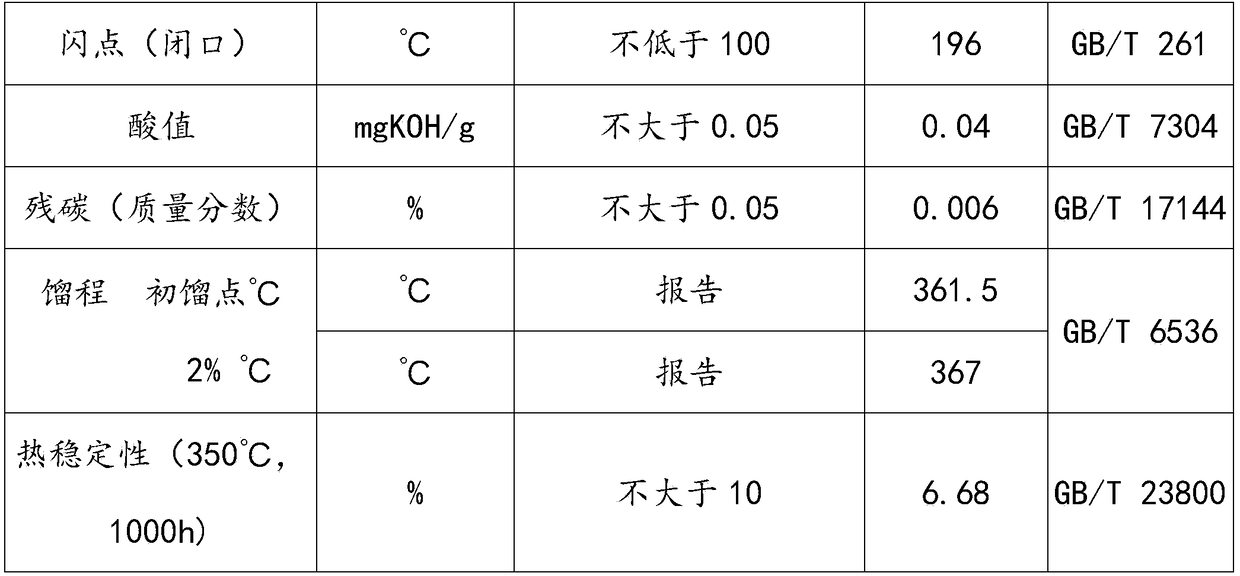

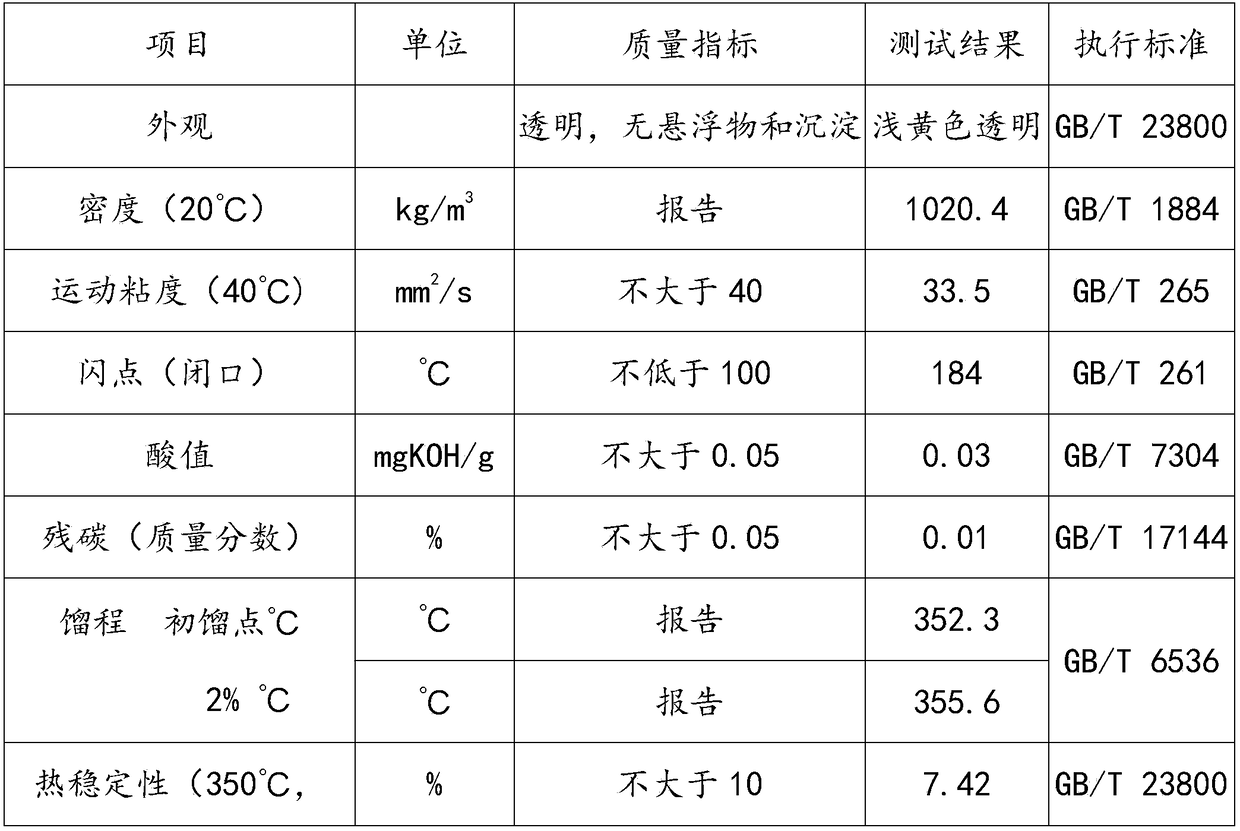

[0030] Obtain the cyclohexylbiphenyl composition according to the method in Example 1, mix it with commercially available hydrogenated terphenyl according to the mass ratio of 1:1, and perform performance test and thermal stability test on the mixed sample, the test results are as follows 3 shows:

[0031] table 3

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com