Solid tyre

A technology of solid tires and tires, applied in special tires, tire parts, non-pneumatic tires, etc., can solve the problems of poor portability, poor wear resistance, poor load capacity, etc., and achieve increased cushioning and shock absorption, excellent mechanical properties , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

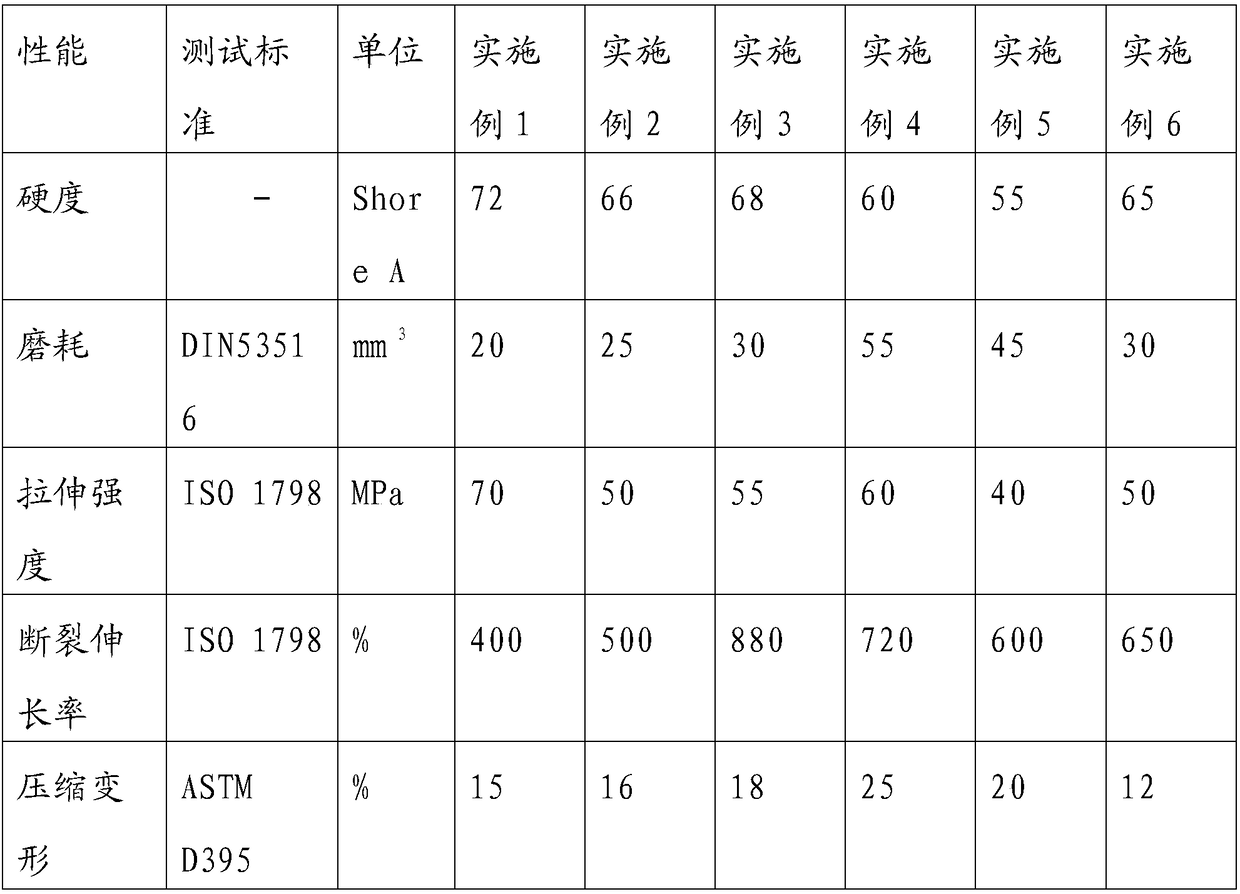

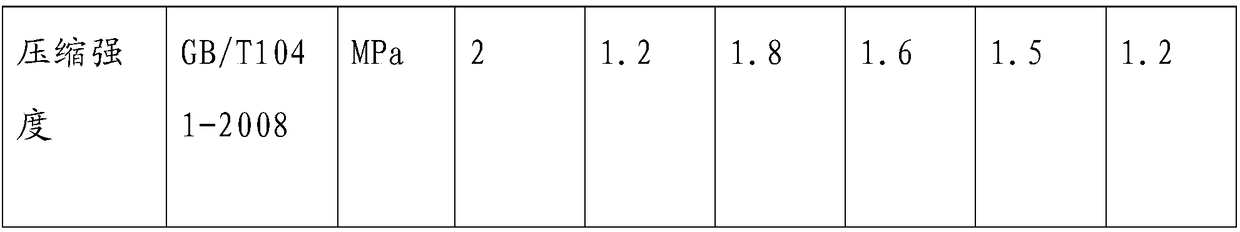

Embodiment 1

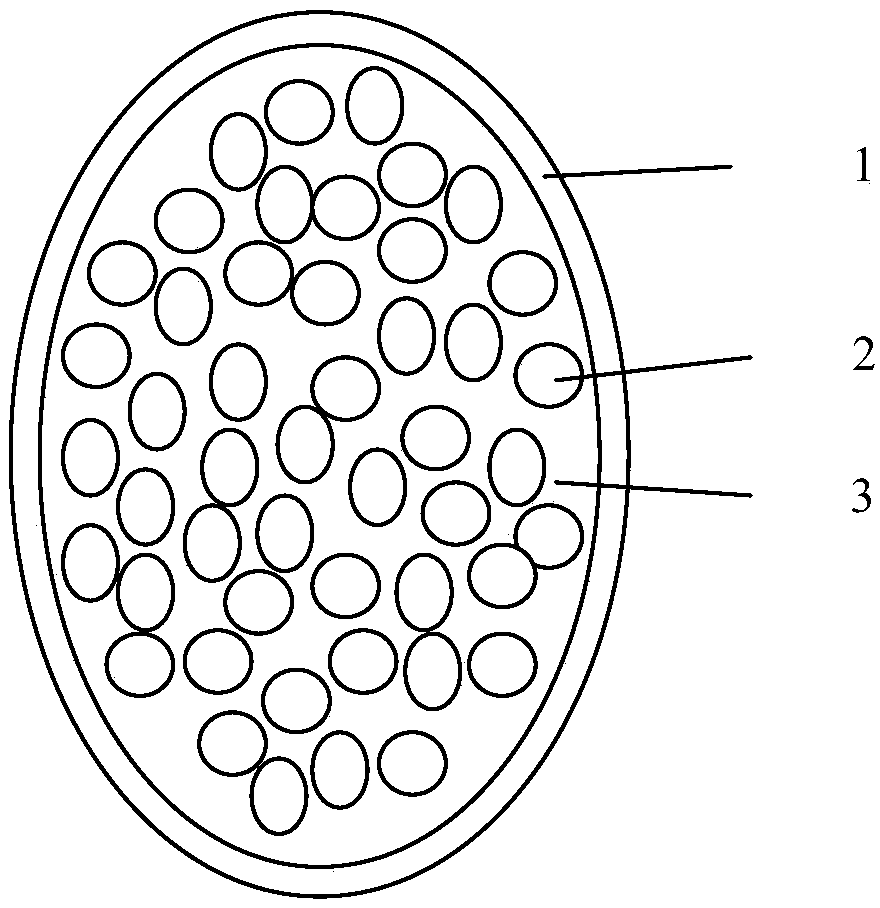

[0031] A solid tire includes an outer layer and an inner core structure. The outer layer of the tire is a conventional rubber tire; the inner core of the tire is made of CPU with a density of 0.1g / cm 3 The expanded polypropylene particles are obtained by molding the composite material with a mass ratio of 1:0.5.

[0032] The above CPU, in parts by weight, consists of the following raw materials: 40 parts by weight of MDI, 65 parts by weight of polyether glycol with a molecular weight of 1000 g / mol, 8 parts by weight of ethylene glycol, 0.2 parts by weight of triethylamine and 0.5 parts by weight. Composition of silica in parts by weight;

[0033] The above-mentioned molding process is as follows: the components of the CPU and the expanded polypropylene particles are uniformly mixed in the mixing equipment and then filled into the tire core mold, the mold is closed, the temperature is set to 80°C, the pressure is set to 0.6MPa, and the The time is 2 minutes, the cooling time is 5 m...

Embodiment 2

[0036] A solid tire includes an outer layer and an inner core structure. The outer layer of the tire is a conventional rubber tire; the inner core of the tire is made of CPU with a density of 0.15g / cm 3 The expanded polyethylene particles are formed by a molding process according to a composite material with a mass ratio of 1:1.

[0037] The above CPU, in parts by weight, consists of the following raw materials: 42 parts by weight of TDI, 60 parts by weight of polyester diol with a molecular weight of 1500 g / mol, 5 parts by weight of hexanediol, 0.8 parts by weight of stannous diacetate and 2 parts by weight of zinc oxide;

[0038] The above-mentioned molding process is as follows: the components of the CPU and the expanded polypropylene particles are uniformly mixed in the mixing equipment and then filled into the tire core mold, the mold is closed, the temperature is set at 90°C, the pressure is set at 0.8MPa, and the The time is 15 minutes, the cooling time is 10 minutes, and t...

Embodiment 3

[0041] A solid tire includes an outer layer and an inner core structure. The outer layer of the tire is a conventional rubber tire; the inner core of the tire is made of CPU with a density of 0.25g / cm 3 The foamed thermoplastic polyurethane particles are formed by a molding process according to a composite material with a mass ratio of 1:2.

[0042] The above CPU is based on parts by weight and is composed of the following raw materials: 35 parts by weight of MDI, 68 parts by weight of polyester diol with a molecular weight of 2000 g / mol, 7 parts by weight of 1,4 butanediol, and 0.3 parts by weight of dilaurin It is composed of dibutyl tin acid and 1 part by weight of talc;

[0043] The above-mentioned molding process is as follows: mix the components of the above-mentioned CPU and the foamed polypropylene particles in the mixing equipment, and then fill them into the tire core mold, close the mold, set the temperature at 60°C, set the pressure at 0.2MPa, and solidify The time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com