Sewage purification material and preparation method thereof

A technology for purifying materials and sewage, applied in the field of water purification, can solve problems such as low treatment efficiency, achieve the effects of improving flocculation, maintaining water absorption and flocculation, and improving and reducing the performance of water COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

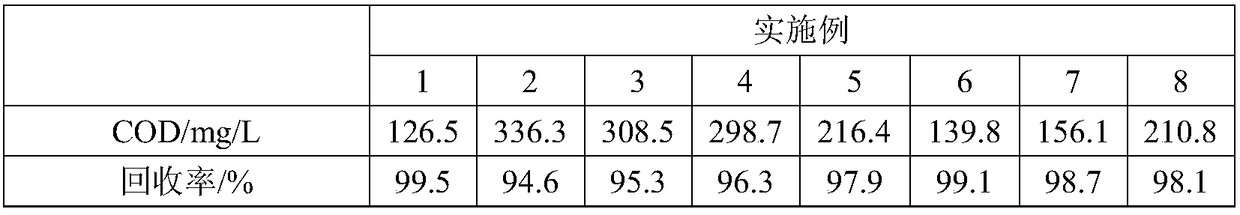

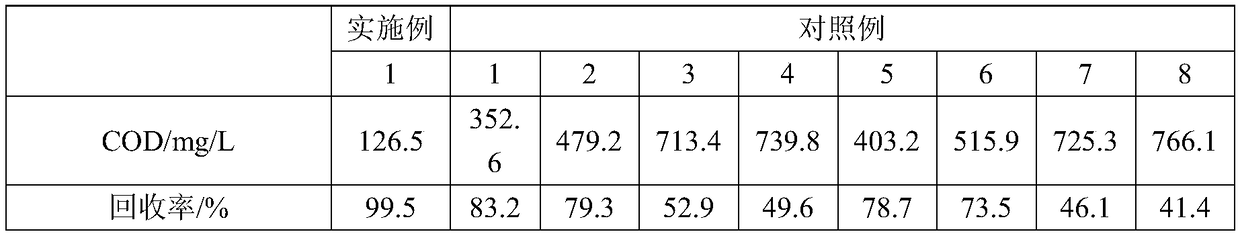

Examples

Embodiment 1

[0021] A kind of purification material for sewage, its preparation method comprises the following steps:

[0022] (1) Weigh 36 parts of ferric chloride, 5.9 parts of water, 75 parts of ethanol and 1.7 parts of polyethylene glycol 1000 and add them to the reaction kettle, the stirring speed is 125r / min, and the reaction is carried out under the condition of maintaining the reaction temperature of the system at 65°C After 16 minutes, 13 parts of formic acid were added to the reactor at an addition rate of 0.02 parts / min, and the reaction was continued for 3.5 hours under the above reaction conditions to obtain the precursor of ferric oxide;

[0023] (2) Weigh 19 parts of polyaluminum chloride, 65 parts of ethanol and 1.6 parts of polyethylene glycol 600 and add them to the reaction kettle, the stirring speed is 100r / min, and the reaction temperature is maintained at 50°C for 25 minutes, and the 51 Parts of ferroferric oxide precursor were added to the reactor at a rate of 0.05 p...

Embodiment 2

[0028]A kind of purification material for sewage, its preparation method comprises the following steps:

[0029] (1) Weigh 36 parts of ferric chloride, 2 parts of water, 68 parts of ethanol and 0.3 parts of polyethylene glycol 1000 and add them to the reaction kettle, the stirring speed is 125r / min, and the reaction is carried out under the condition of maintaining the reaction temperature of the system at 65°C After 16 minutes, 8.7 parts of formic acid were added to the reactor at an addition rate of 0.02 parts / min, and the reaction was continued for 1 hour while maintaining the above reaction conditions to obtain a precursor of ferric oxide;

[0030] (2) Weigh 17 parts of polyaluminum chloride, 53 parts of ethanol and 0.8 parts of polyethylene glycol 600 and add them to the reaction kettle, the stirring speed is 100r / min, and the reaction temperature is maintained at 50°C for 25 minutes. Add the precursor of ferroferric oxide to the reactor at the rate of 0.05 parts / min, con...

Embodiment 3

[0035] A kind of purification material for sewage, its preparation method comprises the following steps:

[0036] (1) Weigh 36 parts of ferric chloride, 8 parts of water, 83 parts of ethanol and 3 parts of polyethylene glycol 1000 and add them to the reaction kettle, the stirring speed is 125r / min, and the reaction is carried out under the condition of maintaining the reaction temperature of the system at 65°C 16 minutes, 21 parts of formic acid were added to the reactor at a rate of 0.02 parts / min, and the reaction was continued for 5 hours while maintaining the above reaction conditions to obtain a precursor of ferric oxide;

[0037] (2) Weigh 23 parts of polyaluminum chloride, 70 parts of ethanol and 5 parts of polyethylene glycol 600 and add them to the reaction kettle, the stirring speed is 100r / min, and the reaction temperature is maintained at 50°C for 25 minutes, and the 51 Parts of ferroferric oxide precursor were added to the reactor at a rate of 0.05 parts / min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com