A preparation method of sulfide heterojunction material resistant to light corrosion in photo-Fenton reaction

A technology for anti-light corrosion and sulfide, which is applied in chemical instruments and methods, chemical/physical processes, catalyst protection, etc., and can solve problems such as hidden dangers of instability and aggravated sulfide corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

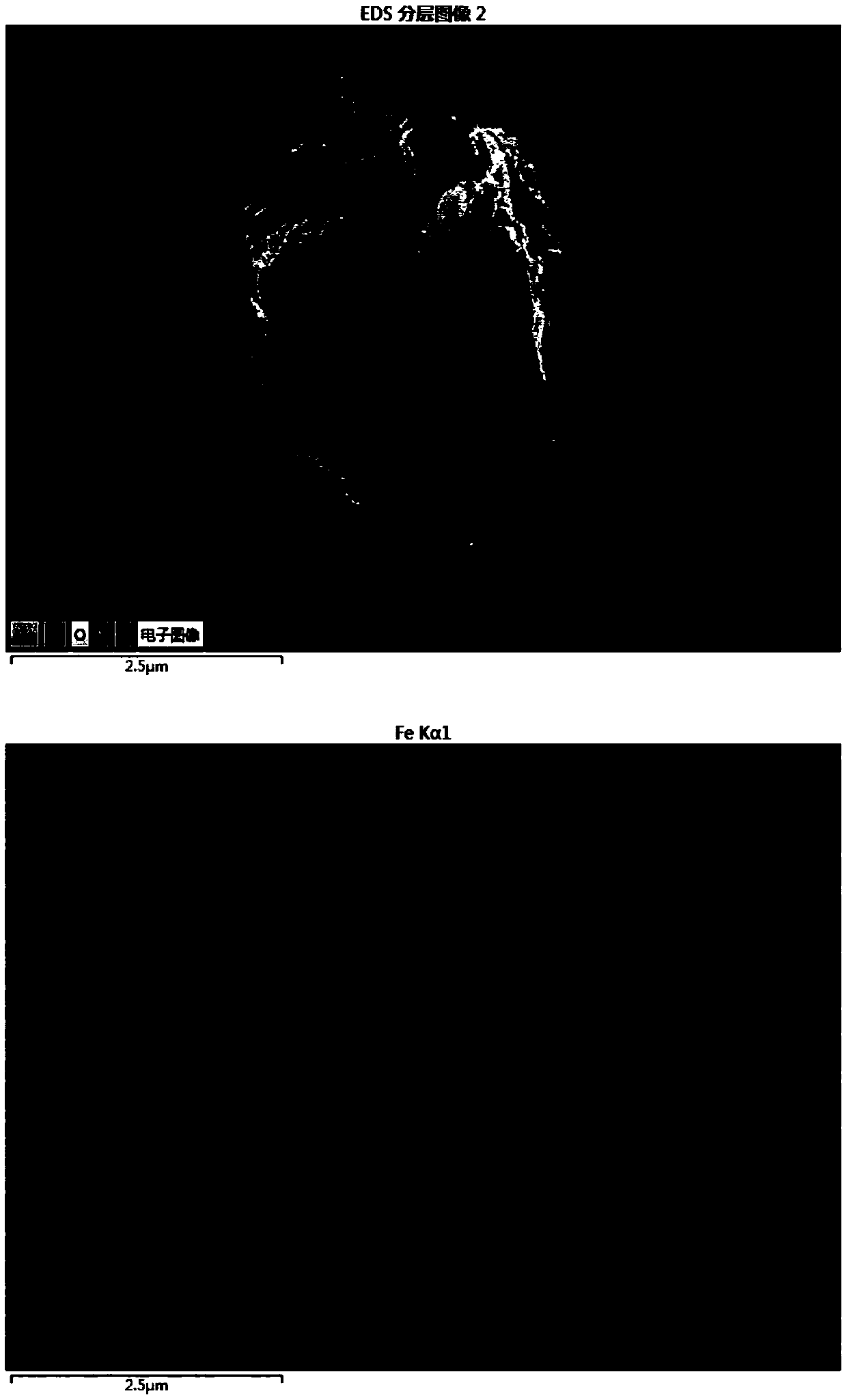

Image

Examples

Embodiment 1

[0022] Embodiment 1: the α-Fe used in this embodiment 2 o 3 Nanoparticles were prepared as follows: 5 mmol FeCl 3 ·6H 2 O was dissolved in 20 mL of absolute ethanol, and after ultrasonic vibration for 30 min, 3.4 mL of deionized water and 5 mmol of sodium acetate were successively added, vigorously stirred at 300 rpm for 1 h, then hydrothermally reacted at 200 °C for 24 h, and cooled to room temperature after the reaction was completed. The solid was taken out, washed 3 times with absolute ethanol and 3 times with deionized water, kept in a vacuum oven at 60°C for 10 hours, and then taken out for use.

[0023] In this implementation, a preparation method of a sulfide heterojunction material resistant to light corrosion in the photo-Fenton reaction is completed through the following steps:

[0024] Step 1, 0.25mmol, 0.375mmol, 0.5mmol, 0.75mmolα-Fe 2 o 3 Nanoparticles were added to 40mL deionized water, stirred at 300rpm, and then 1.5mmolNa 2 MoO 4 2H 2 O and 9 mmol CH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com