Preparation method of vitamin E

A vitamin and catalyst technology, applied in the field of vitamin E preparation, achieves the effects of high purity, less equipment corrosion, and lower industrial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

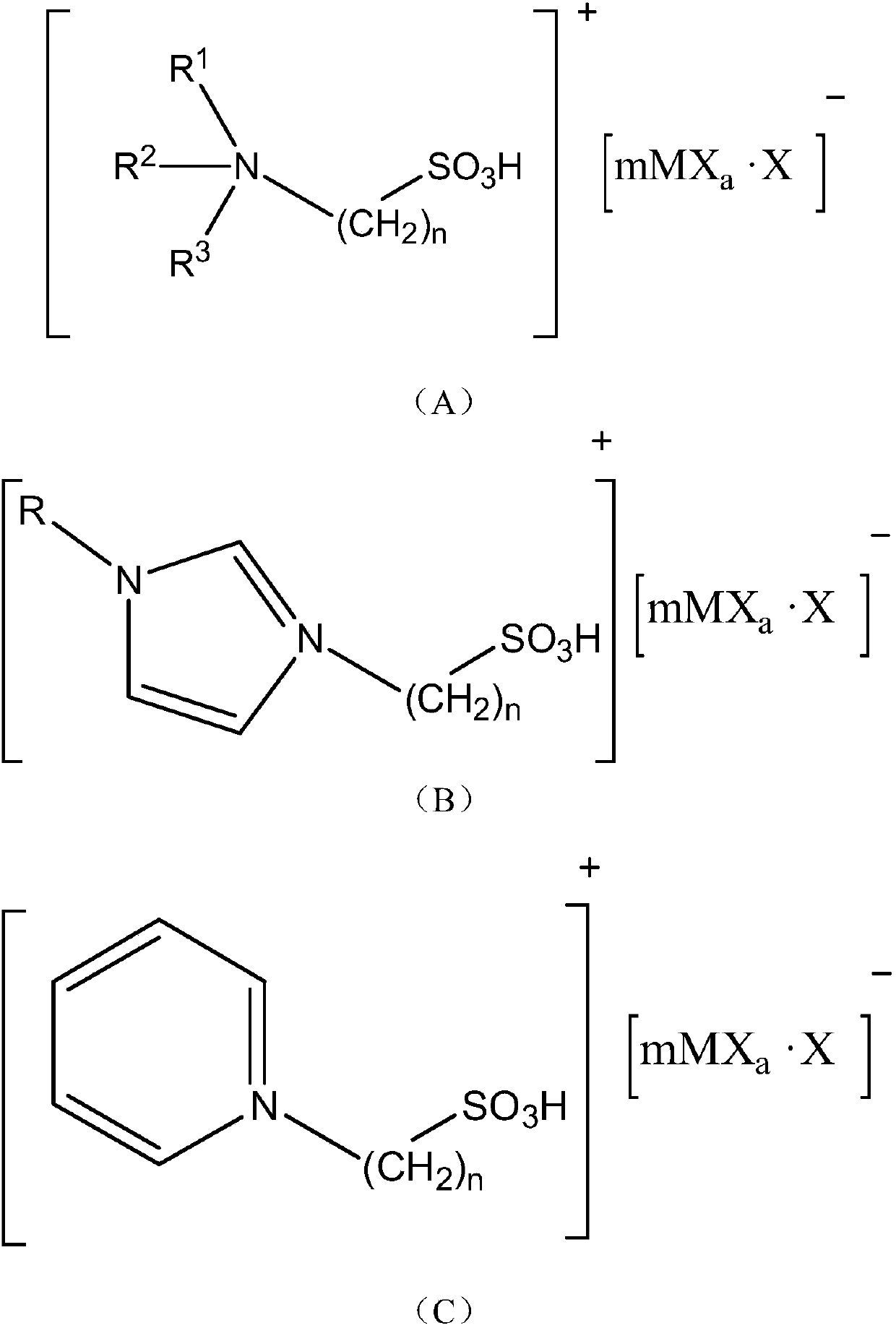

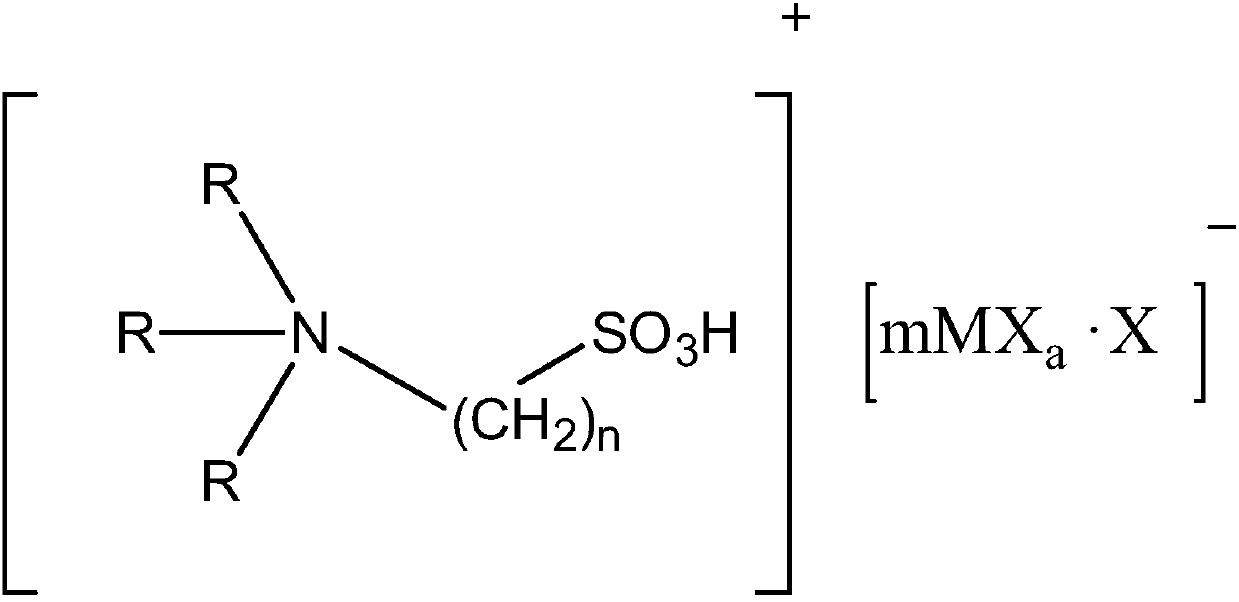

Method used

Image

Examples

Embodiment 1

[0034] In the reaction vessel, add 91.31g (0.6mol) trimethylhydroquinone and 14.87g 3-sulfonic acid propyltrimethylamine chloride zincate [HO 3 S-(CH 2 ) 3 -NMe 3 ][Cl 2ZnCl 2 ], stirred, heated to 99°C under the protection of nitrogen, and slowly added dropwise 177.92g (0.6mol) of isophytic alcohol for 45 minutes. After the reaction is finished, let it stand for cooling, then take the upper and lower layer liquids to recover the solvent under reduced pressure, and obtain the product and the catalyst respectively.

[0035] The product is sampled, and the sample method refers to GB / T 9454-2008, gas chromatography, and the condensation reaction yield is 96.5%.

Embodiment 2

[0037] Add successively 91.31g (0.6mol) trimethylhydroquinone and 14.87g 3-sulfonic acid propyltrimethylamine chloride zincate [HO 3 S-(CH 2 ) 3 -NMe 3 ][Cl 2ZnCl 2 ], stirred, heated to 40° C. under the protection of argon, and slowly added dropwise 177.92 g (0.6 mol) of isophytic alcohol for 1 hour. After the dropwise addition, the mixture was incubated for 3 hours. After the reaction is finished, let it stand for cooling, then take the upper and lower layer liquids to recover the solvent under reduced pressure, and obtain the product and the catalyst respectively.

[0038] The product is sampled, and the sample method refers to GB / T 9454-2008, gas chromatography, and the condensation reaction yield is 92.0%.

Embodiment 3

[0040] Add successively 91.31g (0.6mol) trimethylhydroquinone and 14.87g 3-sulfonic acid propyltrimethylamine dissolved in 530ml heptane / ethylene carbonate (5:4v / v) mixed solvent Chlorozincate [HO 3 S-(CH 2 ) 3 -NMe 3 ][Cl 2ZnCl 2 ], stirred, heated to 140° C. under the protection of helium, and added dropwise 177.92 g (0.6 mol) of isophytic alcohol for 20 minutes, and kept the reaction for 40 minutes after the dropwise addition was completed. After the reaction is finished, let it stand for cooling, then take the upper and lower layer liquids to recover the solvent under reduced pressure, and obtain the product and the catalyst respectively.

[0041]The product is sampled, and the sample method refers to GB / T 9454-2008, gas chromatography, and the condensation reaction yield is 92.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com