Spice by using tea leaf crude and old leaves as main raw material and preparation method thereof

A technology for the main raw material and tea, which is applied in the field of spice and its preparation with crude and old tea leaves as the main raw material, can solve the problems of environmental pollution, harmful substances and the like, and achieves the enhancement of spirit, strong antibacterial ability, and improvement of tea taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

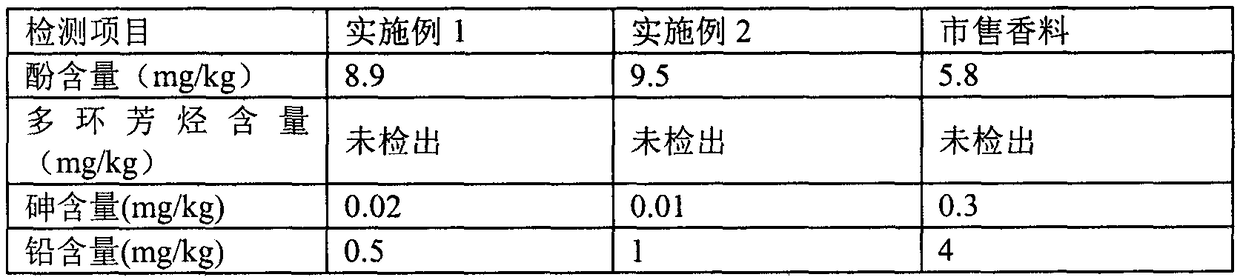

Examples

Embodiment 1

[0024] Raw materials: 20kg of tea stems, 30kg of old tea leaves, 15kg of mint, 30kg of mugwort leaves, 10kg of camphor, 12kg of patchouli, 23kg of tangerine peel, 18kg of comfrey, 15kg of lemongrass, 21kg of fragrant leaves, 8kg of fennel and 20kg of lilies. Concrete preparation steps are as follows:

[0025] 1) Pulverization After the raw materials are weighed in parts by weight, they are mixed, dried and pulverized, and passed through a 30-mesh sieve to obtain a mixture;

[0026] 2) Low-temperature drying Put the mixture into an oven and dry it at 40°C for 60 minutes;

[0027] 3) To enhance the fragrance, place the low-temperature dried mixture at 130°C to enhance the fragrance for 2 minutes;

[0028] 4) Tablet pressing and bar pressing: add starch and vegetable protein to the mixture after aromatherapy, and then extrude from the die hole;

[0029] 5) Curing Put the pressed mixture at 50°C to cure for 30 minutes;

[0030] 6) Packing After solidification, the obtained mixt...

Embodiment 2

[0032] Raw materials: 40kg of old tea leaves, 50kg of tea dregs, 25kg of mint, 40kg of mugwort leaves, 23kg of camphor, 24kg of patchouli, 34kg of tangerine peel, 37kg of comfrey, 27kg of lemongrass, 25kg of fragrant leaves, 15kg of fennel and 35kg of lilies. Concrete preparation steps are as follows:

[0033] 1) Pulverization After the raw materials are weighed in parts by weight, they are mixed, dried and pulverized, and passed through a 40-mesh sieve to obtain a mixture;

[0034] 2) Low-temperature drying Put the mixture into an oven and dry at 60°C for 30 minutes;

[0035] 3) To enhance the fragrance, place the low-temperature dried mixture at 150°C to enhance the fragrance for 1 minute;

[0036] 4) Tablet pressing and bar pressing: add the aroma-promoted compound into natural resin and vegetable protein for bonding, and then extrude from the die hole;

[0037] 5) Curing Put the pressed mixture at 55°C and cure for 20 minutes;

[0038] 6) Packing After solidification, t...

Embodiment 3

[0040] Raw materials: 40kg of tea stems, 40kg of old tea leaves, 20kg of mint, 35kg of mugwort leaves, 15kg of camphor, 18kg of patchouli, 27kg of tangerine peel, 25kg of comfrey, 20kg of lemongrass, 23kg of fragrant leaves, 12kg of fennel and 25kg of lilies. Concrete preparation steps are as follows:

[0041] 1) Pulverization After the raw materials are weighed in parts by weight, they are mixed, dried and pulverized, and passed through a 30-mesh sieve to obtain a mixture;

[0042] 2) Low-temperature drying Put the mixture into an oven and dry it at 50°C for 40 minutes;

[0043] 3) To enhance the fragrance, place the low-temperature dried mixture at 140°C for 1 minute;

[0044] 4) Tablet pressing and bar pressing: Add starch and natural resin to the mixture after aromatherapy, and then extrude from the die hole;

[0045] 5) Curing Put the pressed mixture at 52°C and cure for 25 minutes;

[0046] 6) Packing After solidification, the obtained mixture is cut neatly, packed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com