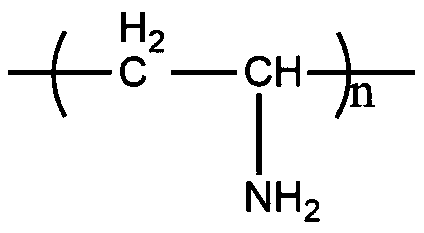

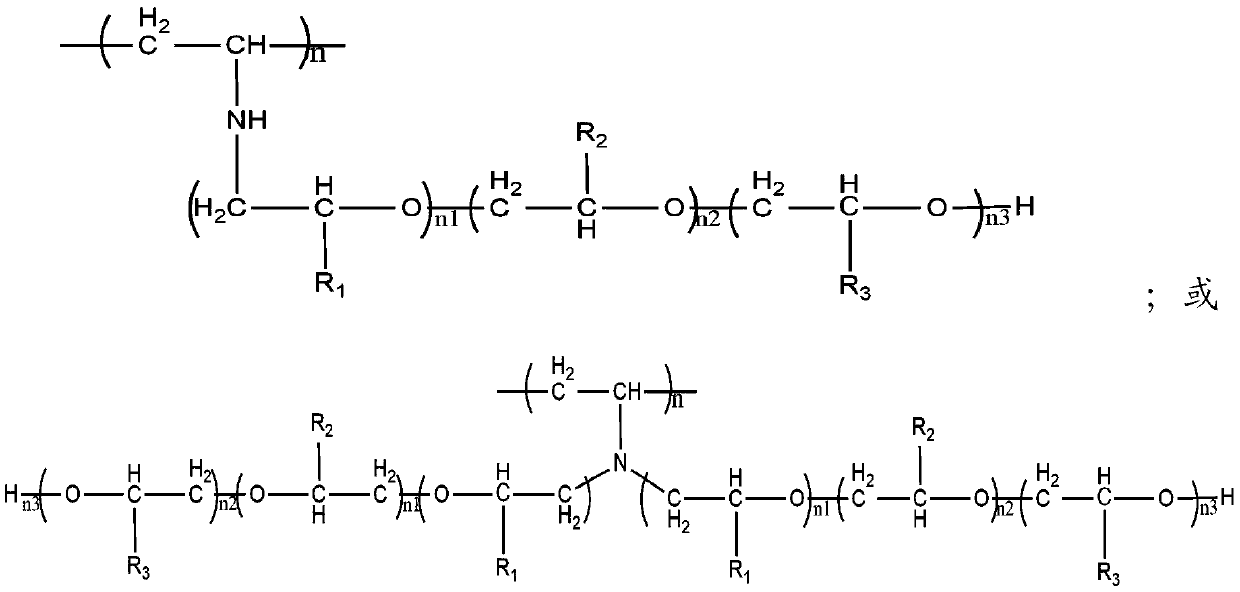

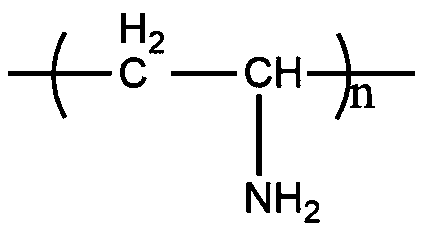

A kind of surfactant and preparation method for improving pesticide droplet dispersion interface performance

A surfactant and interface performance technology, applied in the fields of botanical equipment and methods, insecticides, biocides, etc., can solve the problems of limited application and promotion process, harm to the male reproductive system, and difficult to industrialize production, etc. Effects of physical stability, reduction of liquid loss, and increased uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The embodiment of the present invention discloses a preparation method of a surfactant for improving the dispersion interface performance of pesticide droplets, which specifically includes the following steps:

[0051] (1) Preparation of polyvinylamine alkoxylate B aqueous solution

[0052] (a) First add polyvinylamine A aqueous solution to the reaction kettle, then replace the air in the reaction kettle with nitrogen for 3 times, and raise the temperature to 80-90°C;

[0053] (b) feed epoxy compound again, and feed nitrogen to control the pressure to 0.15-0.35 MPa, and at the same time control the temperature to 80-90 °C, and carry out the aging reaction for 1-3 hours until the end of the pressure equilibrium reaction;

[0054] (c) Finally, evacuate the volatile components under the condition of 80-85° C. to obtain the aqueous solution of polyvinylamine alkoxylate B.

[0055] (2) Preparation of polyvinylamine alkoxy compound C

[0056] (A) First add the polyvinylamin...

Embodiment 1

[0077] The embodiment of the present invention discloses a preparation method of a surfactant for improving the dispersion interface performance of pesticide droplets, which specifically includes the following steps

[0078] (1) In a 2L reactor, add 200g, n is 4, 50% polyvinylamine aqueous solution, and replace it with nitrogen for 3 times, raise the temperature to 80-90°C, feed 205gEO, and feed nitrogen to make the pressure at 0.15-0.35MPa, and aged at 80-90°C for 1-3h, the reaction ends after the pressure remains constant. At 80-85°C, evacuate the volatile components to obtain a 65% aqueous solution of polyvinylamine alkoxylate 1B.

[0079] (2) Add 200 g of polyvinylamine alkoxylate B aqueous solution obtained in step (1) and 1.76 g of NaOH to another 2 L reaction kettle, replace it with nitrogen three times again, raise the temperature to 100-135 ° C, and dehydrate within a certain period of time to make 2 L The moisture content of the material in the reactor is less than ...

Embodiment 2

[0082] The embodiment of the present invention discloses a preparation method of a surfactant for improving the dispersion interface performance of pesticide droplets, which specifically includes the following steps:

[0083](1) In a 2L reaction kettle, add 300g, n is 10, 50% polyvinylamine aqueous solution, and replace it with nitrogen for 3 times, raise the temperature to 80-90°C, feed 614gEO, and feed nitrogen to make the pressure at 0.15-0.35MPa, and aged at 80-90°C for 1-3h, the reaction ends after the pressure remains constant. At 80-85°C, evacuate the volatile components to obtain 68% polyvinylamine alkoxylate 2B aqueous solution.

[0084] (2) Add 200 g of polyvinylamine alkoxylate B aqueous solution and 2.2 g of KOH obtained in step (1) to another 2 L reaction kettle, replace with nitrogen three times again, raise the temperature to 100-135 ° C, and dehydrate within a certain period of time to make 2 L The moisture content of the material in the reactor is less than 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com