Dielectric paste for YH21CT stainless steel thick-film circuits and preparation method thereof

A technology of YH21CT and dielectric paste, which is applied in the direction of circuits, electrical components, quartz/glass/glass enamel, etc., can solve the problems of inability to meet the thermal performance requirements of thick-film circuits, mismatching expansion coefficients, thick-film sintering and oxidation, etc., to achieve Fast heating speed, better bonding performance, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

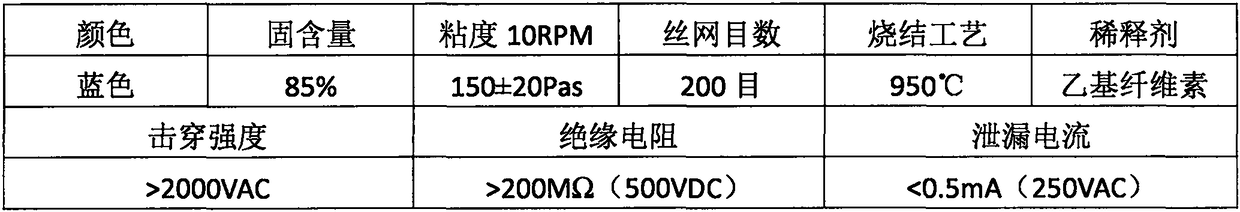

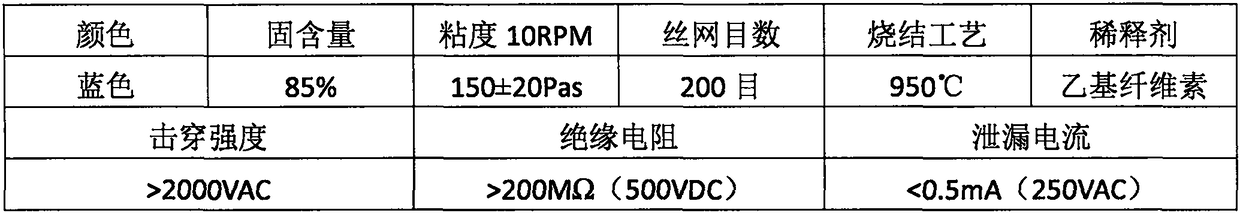

Image

Examples

Embodiment 1

[0016] A dielectric paste for YH21CT stainless steel thick film circuit:

[0017] 1. Glass-ceramic formula: SiO 2 (22%), BaO (5%), Al 2 o 3 (14%), H 3 BO 3 (10%), ZrO 2 (5%), Co. 3 o 4 (4%), MgO (25%), CaO (15%).

[0018] 2. Glass melting method and process: 1500°C, heat preservation for 3 hours.

[0019] 3. Ball milling and particle size control: use a vibrating ball mill for coarse grinding, and then use a planetary ball mill or mixer for fine grinding until the maximum particle size does not exceed 3 microns.

[0020] 4. Organic binder formula and dissolution method and process: tributyl citrate (20%), 1.4-butyrolactone (5%), ethyl cellulose (5%), hydrogenated castor oil (1%), Lecithin (4%), Terpineol (65%). Solvent process After mixing the components prepared in proportion, they are kept in a high-temperature (85-95° C.) water bath for 6 hours.

[0021] 5. Slurry preparation process: put glass-ceramic powder and organic binder in proportion (91:9) into the conta...

Embodiment 2

[0026] A dielectric paste for YH21CT stainless steel thick film circuit:

[0027] 1. Glass-ceramic formula: SiO 2 (20%), Ba0 (6%), Al 2 o 3 (10%), H 3 BO 3 (11%), ZrO 2 (3%), Co. 3 o 4 (5%), MgO (28%), CaO (17%).

[0028] 2. Glass melting method and process: 1500°C, heat preservation for 3 hours.

[0029] 3. Ball milling and particle size control: use a vibrating ball mill for coarse grinding, and then use a planetary ball mill or mixer for fine grinding until the maximum particle size does not exceed 3 microns.

[0030] 4. Organic binder formula and dissolution method and process: tributyl citrate (19%), 1.4-butyrolactone (5%), ethyl cellulose (6.5%), hydrogenated castor oil (1%), Lecithin (4%), Terpineol (64.5%). Solvent process The components prepared in proportion are mixed and then kept in a high temperature (85° C. to 95° C.) water bath for 5 hours.

[0031] 5. Slurry preparation process: Put the glass-ceramic powder and organic binder in proportion (95:5) int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com