Acoustic fluid sensor

A fluid sensor and acoustic sensing technology, which is applied in the direction of transmitting sensing components by wave/particle radiation devices, can solve the problem of low quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

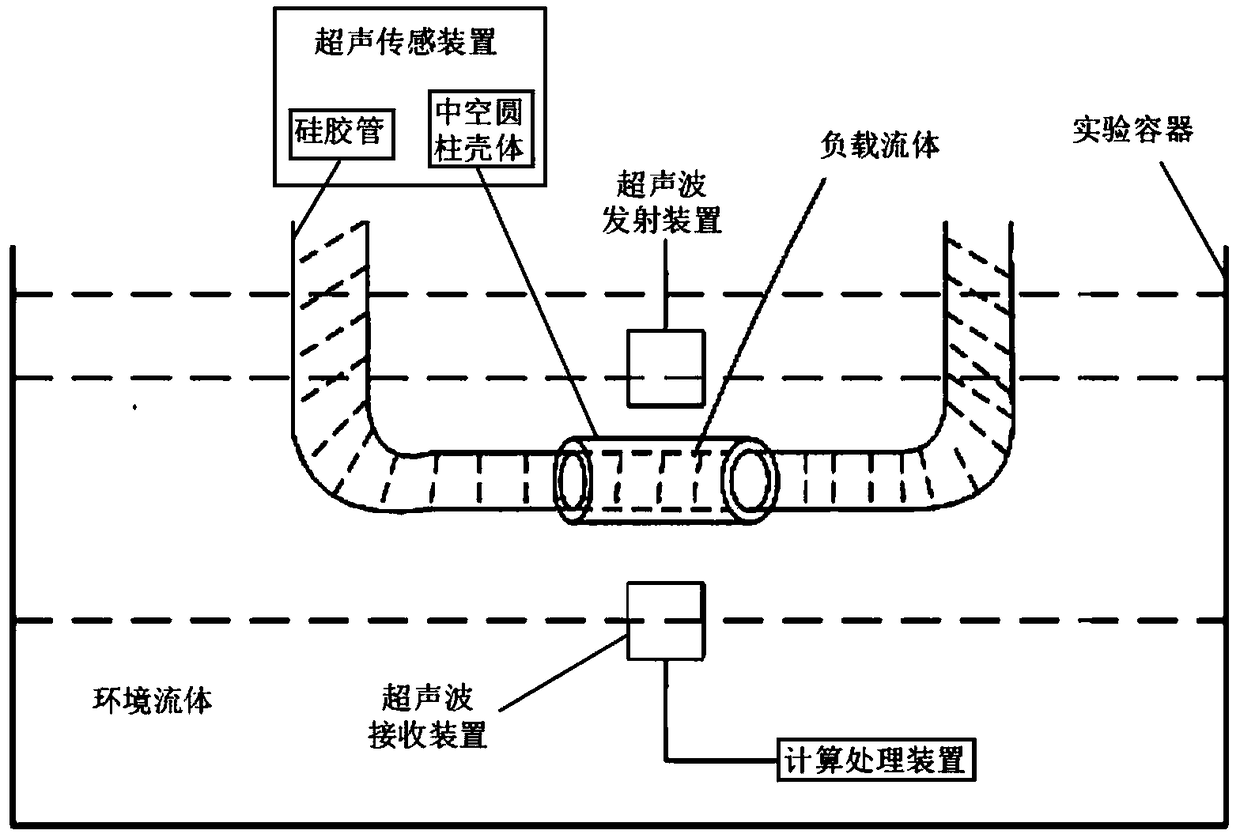

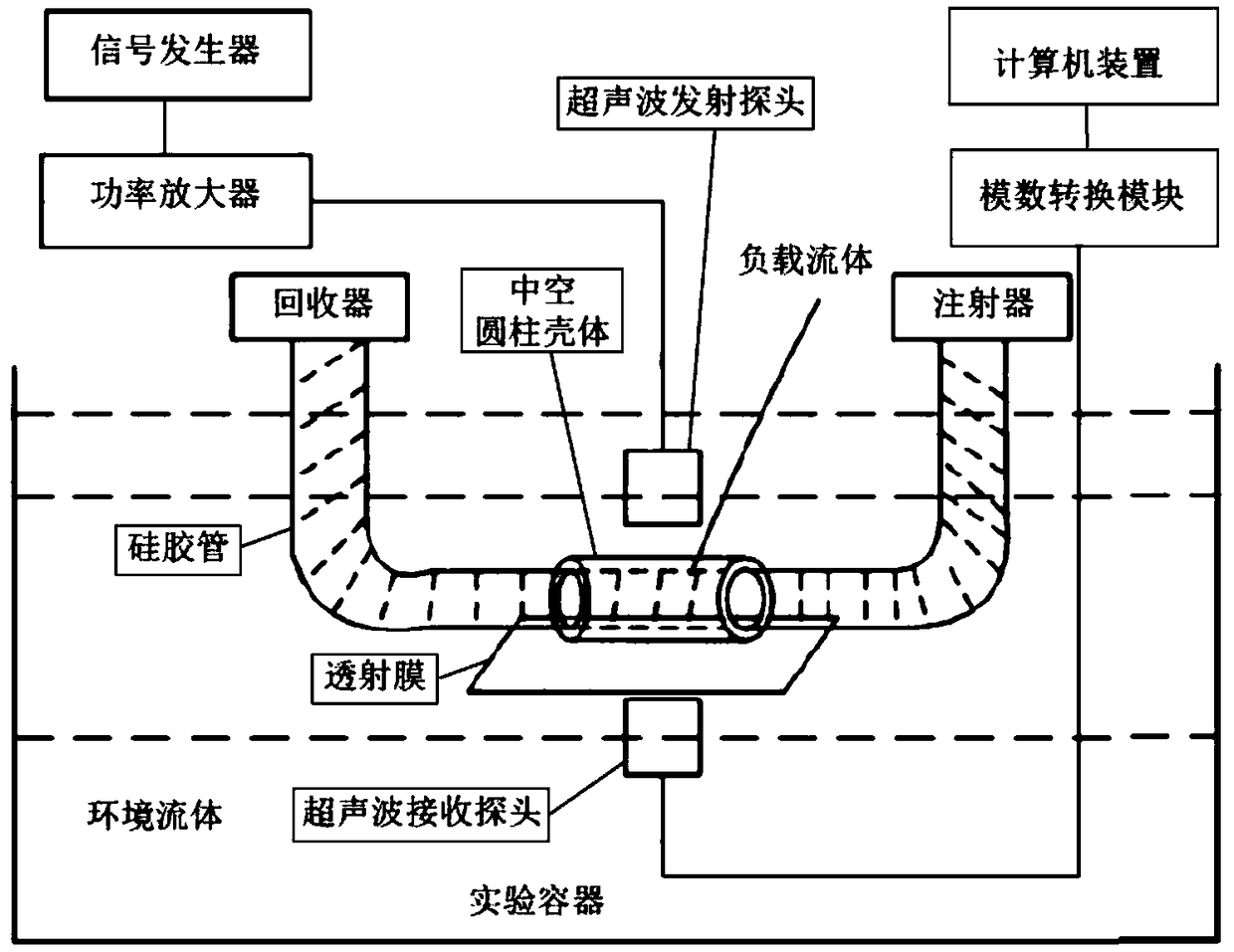

[0024] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0025] Principle of invention

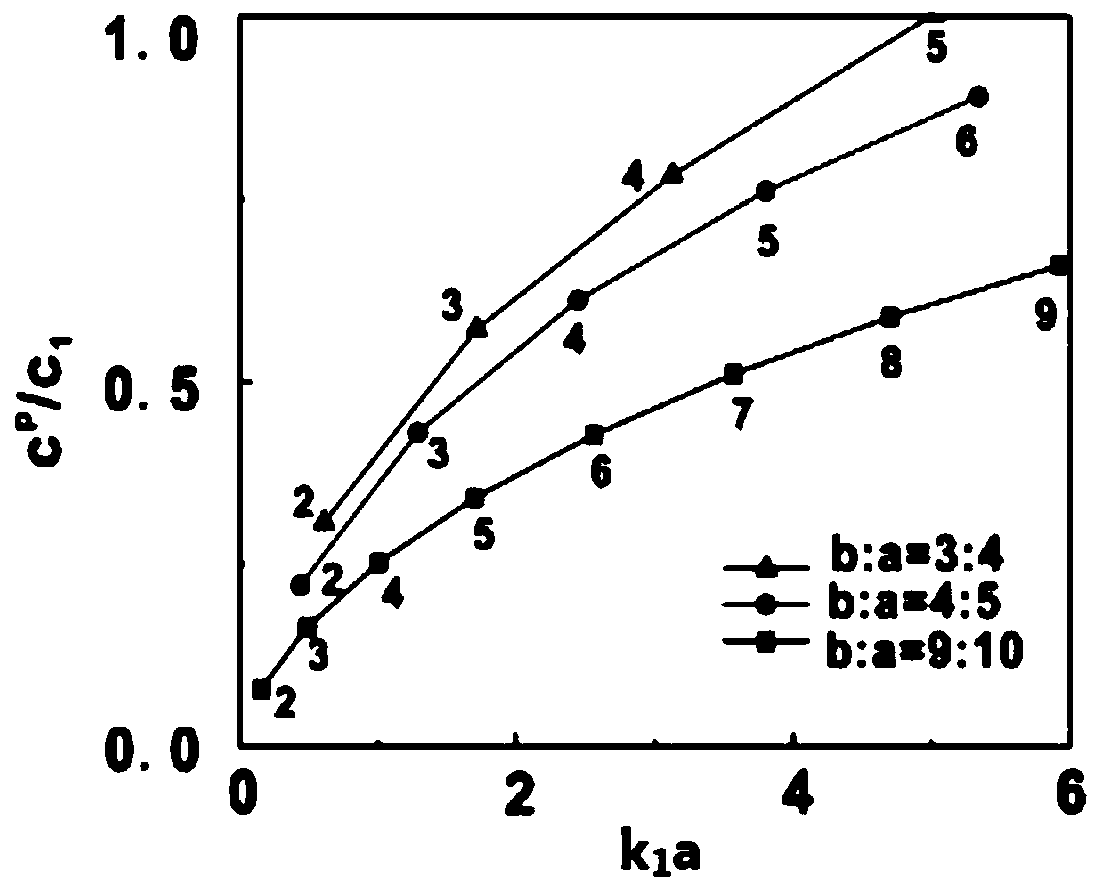

[0026] During the experiment, a load fluid is injected into the hollow cylindrical shell. When a plane simple harmonic wave of a certain eigenfrequency is incident on the finite-length hollow cylindrical shell perpendicular to the axis, the load fluid (standard fluid or to-be-measured fluid) inside the hollow cylindrical shell Fluid) excites Scholte–Stoneley circular waves orbiting along the hollow cylindrical shell. When the phase velocity of the Scholte–Stoneley circular wave satisfies the condition of phase matching, the Scholte–Sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com