High-strength nylon composite and preparation method thereof

A nylon composite material and high-strength technology, which is applied in the field of fiber and modified nano-scale composite reinforced nylon material, high-strength nylon composite material and its preparation, can solve the problem of poor mechanical properties of composite materials, shortened service life of materials, and general appearance. There are problems such as floating fibers, achieving good thermal stability, improving crystallinity, improving interfacial wetting performance and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

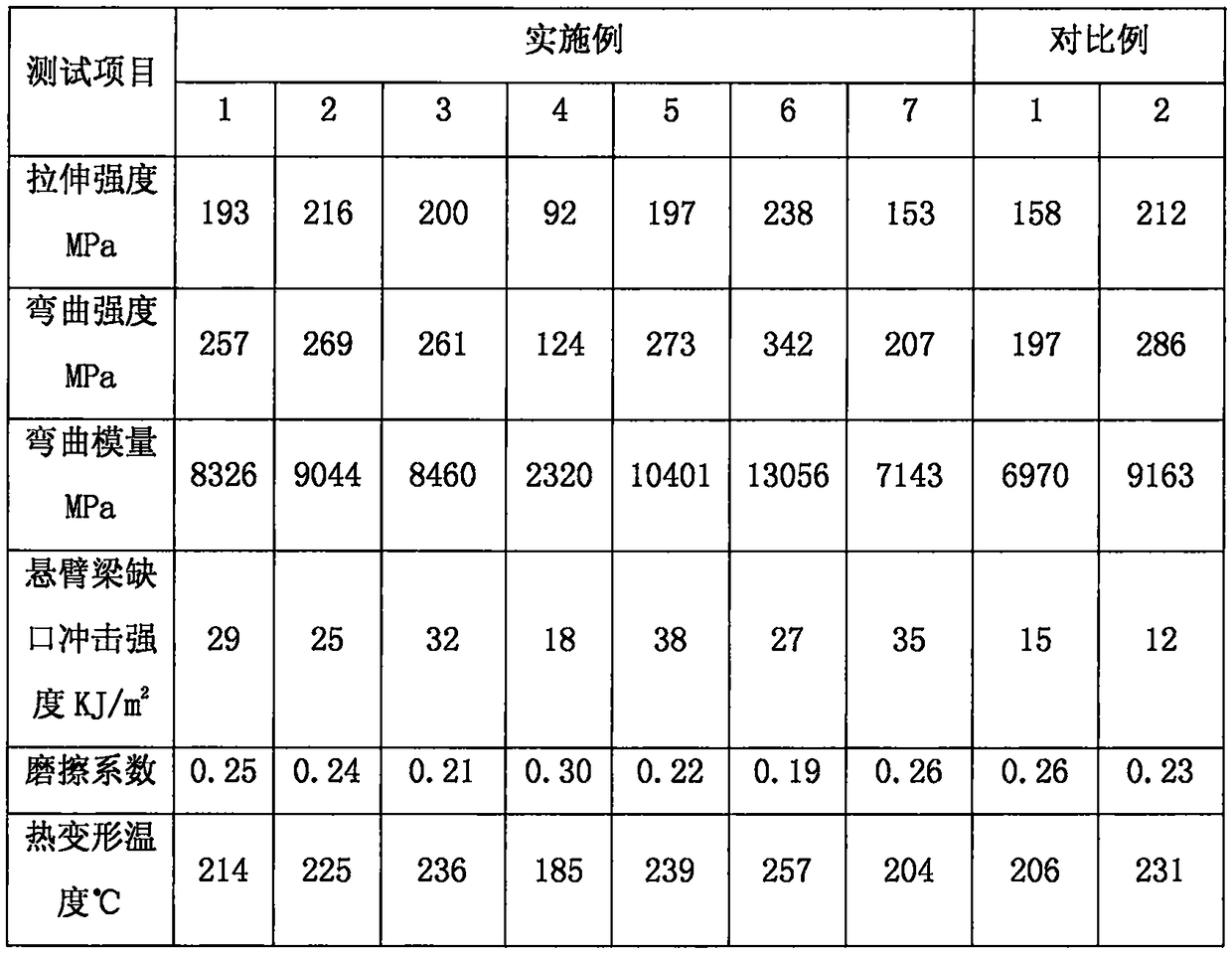

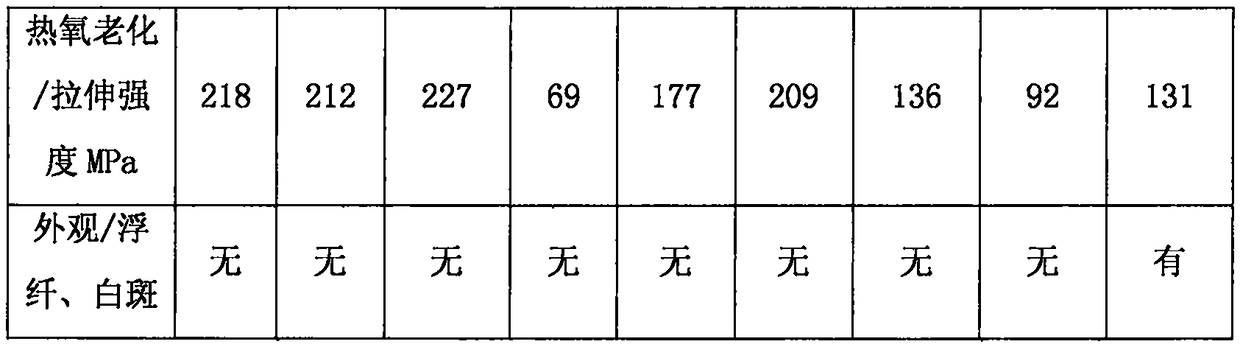

Examples

Embodiment 1

[0039] A high-strength nylon composite material consisting of the following mass percentages:

[0040] 69 parts of nylon 6, 20 parts of chopped glass fiber with a length of 5 mm, 10 parts of multifunctional materials, 0.1 part of 1098, 0.2 part of 168 and 0.2 part of 5524, 0.5 part of silicone powder;

[0041] The preparation method comprises the following steps:

[0042] The processing conditions for melt extrusion of the extruder are as follows: the temperature of the first zone is 210°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 250°C, the temperature of the fifth zone is 260°C, the temperature of the sixth zone is 260°C, and the temperature of the seventh zone 265°C, the temperature in the eighth zone is 270°C, the temperature in the ninth zone is 265°C, the temperature of the machine head is set to 270°C, and the current of the host is 210-230A;

[0043] Nylon, anti-oxidant aging agent a...

Embodiment 2

[0048] A high-strength nylon composite material consisting of the following mass percentages:

[0049] 67 parts of nylon 6, 30 continuous glass fiber, 2 parts of multifunctional material, 0.1 part of 1098, 0.2 part of 168 and 0.2 part of 5524, 0.5 part of silicone powder;

[0050] The preparation method comprises the following steps:

[0051] The processing conditions for melt extrusion of the extruder are as follows: the temperature of the first zone is 210°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 250°C, the temperature of the fifth zone is 260°C, the temperature of the sixth zone is 260°C, and the temperature of the seventh zone 265°C, the temperature in the eighth zone is 270°C, the temperature in the ninth zone is 265°C, the temperature of the machine head is set to 270°C, and the current of the host is 210-230A;

[0052] Nylon, anti-oxidant aging agent and lubricant are added in the ...

Embodiment 3

[0057] A high-strength nylon composite material consisting of the following mass percentages:

[0058] 70.5 parts of nylon 6, 25 parts of chopped basalt fiber with a length of 3 mm, 3 parts of multifunctional materials, anti-oxidant aging agents are 0.1 part of 508, 0.2 part of 626, 0.2 part of 5524 and 0.2 part of 944, 0.8 part of modified ethylene bis-stearin acid amide;

[0059] The preparation method comprises the following steps:

[0060] The processing conditions for melt extrusion of the extruder are as follows: the temperature of the first zone is 210°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 250°C, the temperature of the fifth zone is 260°C, the temperature of the sixth zone is 260°C, and the temperature of the seventh zone 265°C, the temperature in the eighth zone is 270°C, the temperature in the ninth zone is 265°C, the temperature of the machine head is set to 270°C, and the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com