Montmorillonite-chromium iron slag composite rubber filler with flame-retardant and reinforcing properties

A technology of composite rubber and montmorillonite, which is applied in the field of high value-added recycling of resources, can solve the problems of low value-added utilization, single performance, and poor compatibility of montmorillonite and ferrochrome slag, and achieve high value-added resources Effects of recycling and recycling of solid waste resources, increasing layer spacing ratio and specific surface area, and reducing industry costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

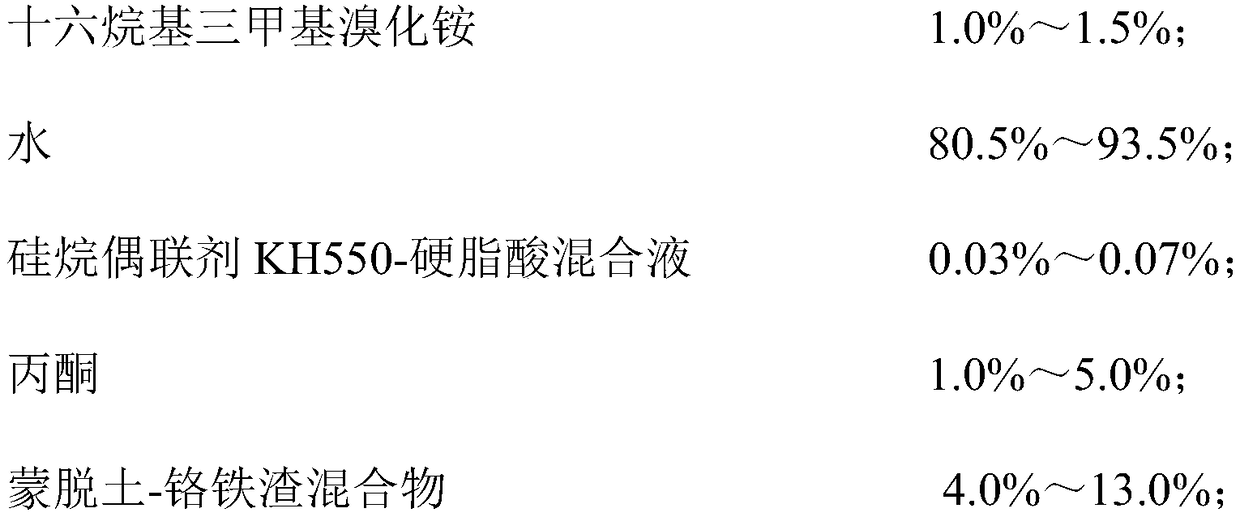

[0020] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0021]

[0022] The mass ratio of silane coupling agent KH550 and stearic acid in the silane coupling agent KH550-stearic acid mixed solution is 1:2, and silane coupling agent KH550 is technically pure, and stearic acid is analytically pure; The mass ratio of montmorillonite to ferrochrome slag in the desoil-ferrochrome slag mixture is 3:1, the montmorillonite is sodium-based montmorillonite, the particle size of ferrochrome slag is 4.8 μm to 110.7 μm, and the chemical composition (mass fraction) for SiO 2 (34.54%), Fe 2 o 3 (5.95%), Al 2 o 3 (23.88%), CaO (0.33%), MgO (25.43%), Cr 2 o 3 (7.64%), SO 3 (0.069%), P 2 o 5 (0.024%) and others (2.137%).

[0023] First, the montmorillonite and water were uniformly mixed at a stirring speed of 2500r / min for 5h and left to stand for 6h to obtain a montmorillonite solution; cetyltrimet...

Embodiment 2

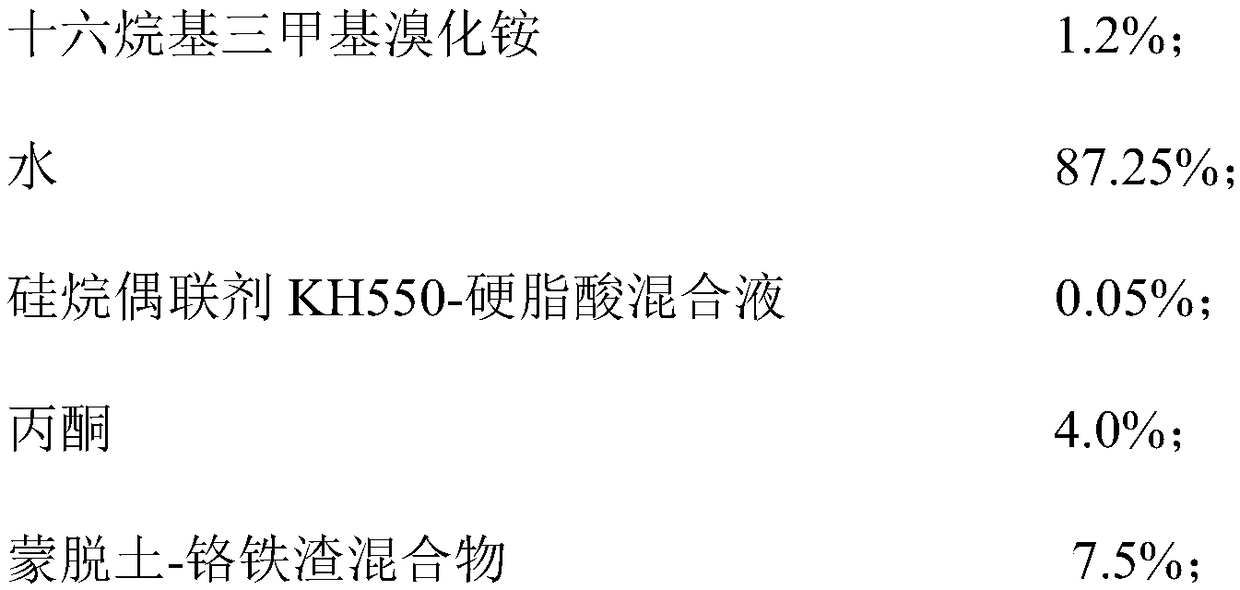

[0025] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0026]

[0027] The mass ratio of silane coupling agent KH550 and stearic acid in the silane coupling agent KH550-stearic acid mixed solution is 3:1, and silane coupling agent KH550 is technically pure, and stearic acid is analytically pure; The mass ratio of montmorillonite to ferrochrome slag in the desoil-ferrochrome slag mixture is 2:1, the montmorillonite is magnesium-based montmorillonite, the particle size of ferrochrome slag is 5.2 μm to 110.3 μm, and the chemical composition (mass fraction) for SiO 2 (35.27%), Fe 2 o 3 (7.26%), Al 2 o 3 (24.03%), CaO (0.38%), MgO (23.68%), Cr 2 o3 (6.89%), SO 3 (0.092%), P 2 o 5 (0.037%) and others (2.361%).

[0028] First, the montmorillonite and water were uniformly mixed at a stirring speed of 3500r / min for 7h and left to stand for 6h to obtain a montmorillonite solution; cetyltrime...

Embodiment 3

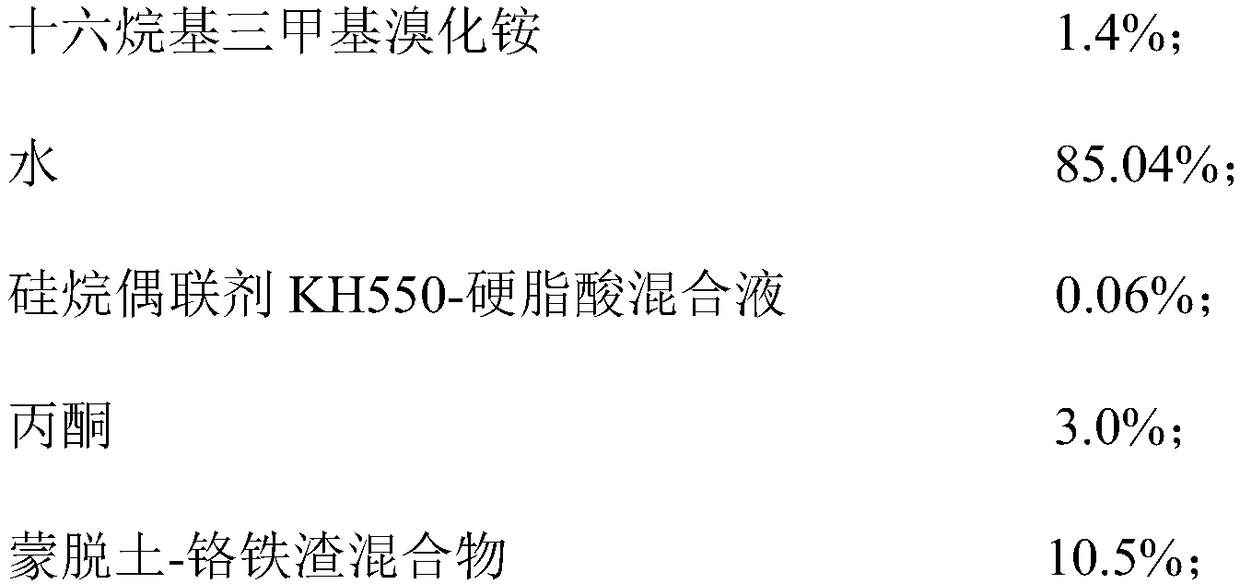

[0030] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0031]

[0032] The mass ratio of silane coupling agent KH550 and stearic acid in the silane coupling agent KH550-stearic acid mixed solution is 1:1, and silane coupling agent KH550 is technically pure, and stearic acid is analytically pure; The mass ratio of montmorillonite to ferrochrome slag in the desoil-ferrochrome slag mixture is 4:1, the montmorillonite is calcium-based montmorillonite, the particle size of ferrochrome slag is 5.0 μm to 100.9 μm, and the chemical composition (mass fraction) for SiO 2 (35.62%), Fe 2 o 3 (6.53%), Al 2 o 3 (24.32%), CaO (0.41%), MgO (24.95%), Cr 2 o 3 (7.05%), SO 3 (0.081%), P 2 o 5 (0.031%) and other (1.008%).

[0033] First, mix montmorillonite and water uniformly at a stirring speed of 2000r / min for 8h and let stand for 6h to obtain a montmorillonite solution; stir cetyltrimethylammoniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com