C40-level high-volume solid waste concrete and preparation method thereof

A technology of waste concrete and large dosage, applied in the field of comprehensive utilization of solid waste and building materials, can solve the problems of many micro-cracks and low strength, and achieve the effect of alleviating extreme shortage, reducing production cost and improving the level of resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

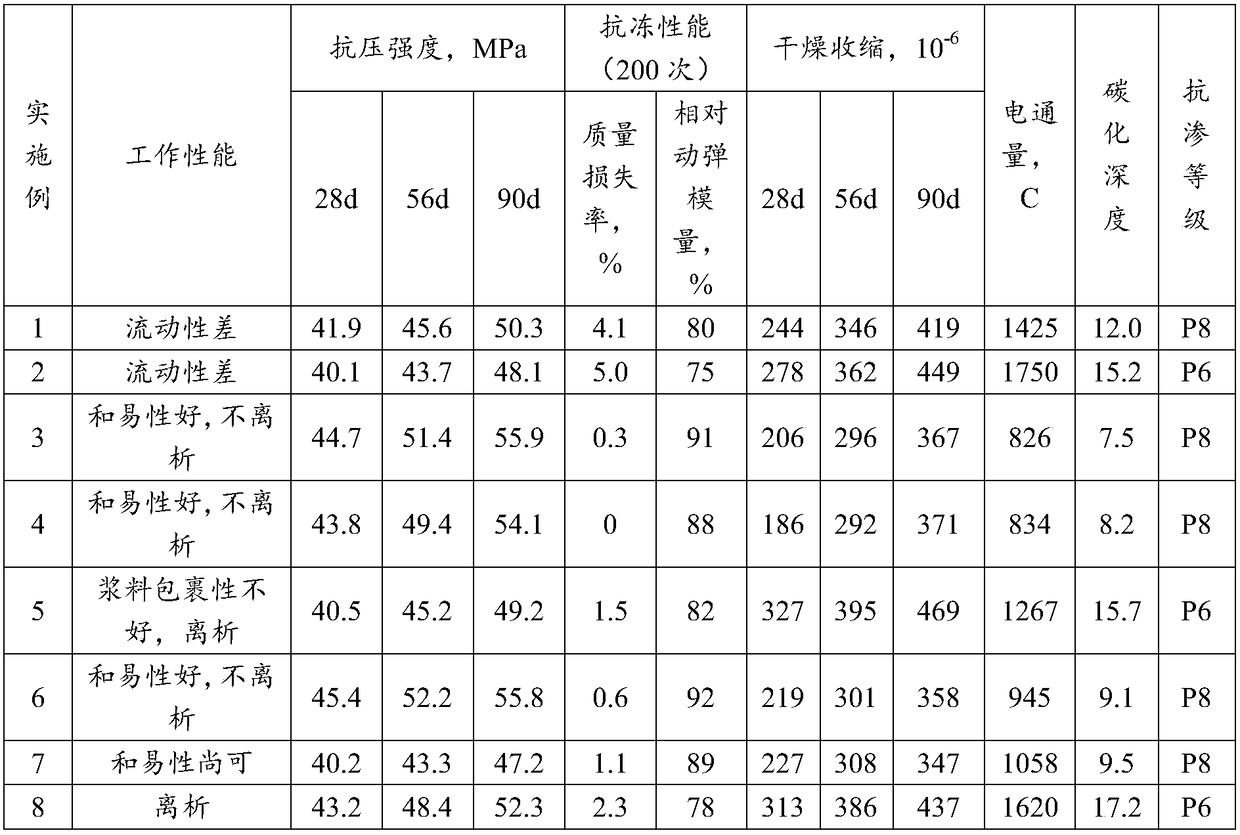

Examples

Embodiment 1~7

[0042] The raw materials for preparing C40 grade large-volume solid waste concrete in Examples 1 to 7 below include: cement, composite admixture, 341 to 367 parts of natural sand, reinforced recycled coarse aggregate, water, polycarboxylate water reducer or composite water reducer. Water agent, one or two mixtures of tailings machine-made sand and recycled fine aggregate; where:

[0043] The cement is P·O42.5 ordinary Portland cement.

[0044] The composite admixture is composed of steel slag, fly ash and mineral powder. According to the total weight of the composite admixture is 100 parts, the steel slag is 8-20 parts, the fly ash is 50-60 parts, and the mineral powder is 30 to 40 copies; of which:

[0045] Steel slag specific surface area > 500cm 2 / g, 28d strength activity index is not less than 85%, via specific surface area 2 / g of steel slag powder mixed with 10% desulfurized gypsum or semi-hydrated desulfurized gypsum for 30 minutes; the desulfurized gypsum is a desul...

Embodiment 1

[0056] per m 3 Concrete contains the following substances in parts by weight:

[0057] P·O4 2.5 cement 213kg, composite admixture (steel slag: fly ash: mineral powder = 1:5:4) 213kg, tailings machine-made sand 313kg, natural sand 364kg, reinforced recycled coarse aggregate (regenerated coarse aggregate After soaking in water glass with a mass concentration of 3% and a modulus of 3.2 for 10 minutes), 1105kg, 4.46kg of polycarboxylate superplasticizer, and 189kg of water.

Embodiment 2

[0059] per m 3 Concrete contains the following substances in parts by weight:

[0060] P·O4 2.5 cement 213kg, composite admixture (steel slag: fly ash: mineral powder = 1:5:4) 213kg, natural sand 364kg, recycled aggregate 313kg, reinforced recycled coarse aggregate (regenerated coarse aggregate Water glass with a mass concentration of 3% and a modulus of 3.2 (soaked for 10 minutes) 1105kg, composite water reducing agent 8.95kg, and water 195kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com