A kind of fluorescent glass material and preparation method thereof, lampshade and lamp

A technology for fluorescent glass and lamps, which is applied in the field of optics, can solve problems such as reduction, LED color drift, and luminous efficiency, and achieve the effects of simplified manufacturing process, good luminous effect, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

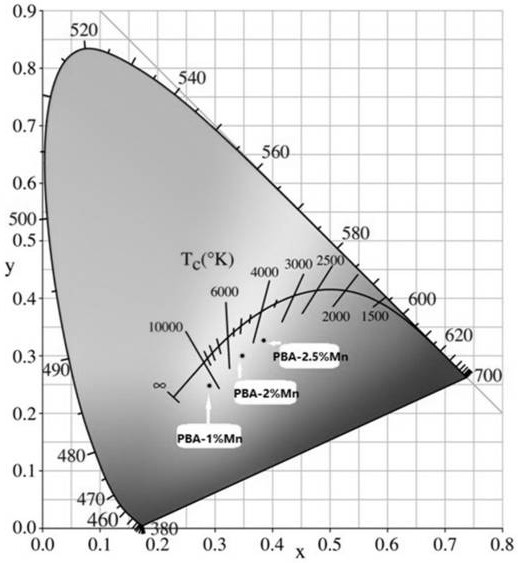

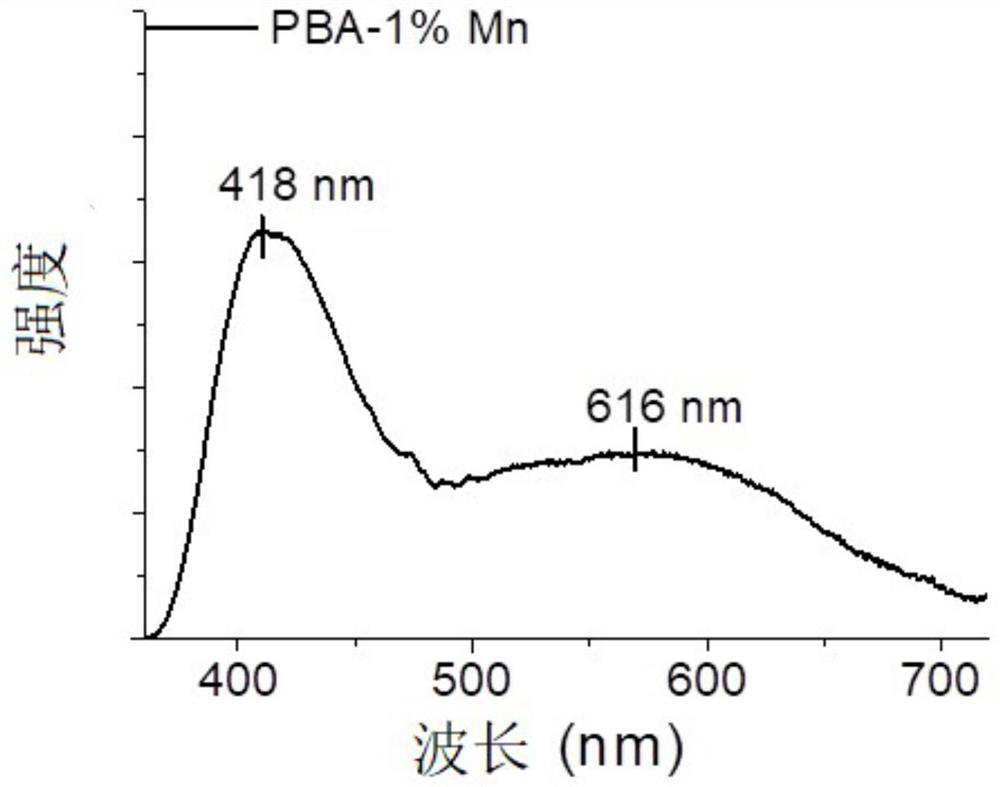

[0065] In this example, the preparation of PBA-1% Mn fluorescent glass material is carried out, and the molar ratio of NH is 56:15:20:10:1. 4 h 2 PO 4 、H 3 BO 3 、Al 2 o 3 , ZnF 2 and MnCO 3 After grinding and pre-mixing evenly, heat it from 25°C to 1450°C at 5°C / min in an air atmosphere in an electric furnace, take it out immediately, pour it on a copper plate at 290°C for quenching, and then anneal at 290°C for 3 hours to obtain the chemical composition (P 2 o 5 ) 0.56 (B 2 o 3 ) 0.15 (Al 2 o 3 ) 0.20 (ZnF 2 ) 0.10 (MnO) 0.01 PBA-1%Mn fluorescent glass material.

Embodiment 2

[0067] In this example, the preparation of PBA-2% Mn fluorescent glass material is carried out, and the molar ratio of NH is 56:15:20:10:2. 4 h 2 PO 4 、H 3 BO 3 、Al 2 o 3 , ZnF 2 and MnCO 3 After grinding and pre-mixing evenly, heat it from 25°C to 1450°C at 5°C / min in an air atmosphere in an electric furnace, take it out immediately, pour it on a copper plate at 290°C for quenching, and then anneal at 290°C for 3 hours to obtain the chemical composition (P 2 o 5 ) 0.56 (B 2 o 3 ) 0.15 (Al 2 o 3 ) 0.20 (ZnF 2 ) 0.10 (MnO) 0.02 PBA-2%Mn fluorescent glass material.

Embodiment 3

[0069] In this example, the preparation of PBA-2.5% Mn fluorescent glass material is carried out, using NH with a molar ratio of 56:15:20:10:2.5 4 h 2 PO 4 、H 3 BO 3 、Al 2 o 3 , ZnF 2 and MnCO 3 After grinding and pre-mixing evenly, heat it from 25°C to 1450°C at 5°C / min in an air atmosphere in an electric furnace, take it out immediately, pour it on a copper plate at 290°C for quenching, and then anneal at 290°C for 3 hours to obtain the chemical composition (P 2 o 5 ) 0.56 (B 2 o 3 ) 0.15 (Al 2 o 3 ) 0.20 (ZnF 2 ) 0.10 (MnO) 0.025 PBA-2.5%Mn fluorescent glass material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com