Purification method of industrial grade ammonium metavanadate

An ammonium metavanadate, industrial-grade technology, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problems of difficult control of K, Na and S content, increase production costs, and affect product quality, etc. The effect of understanding, easy operation, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

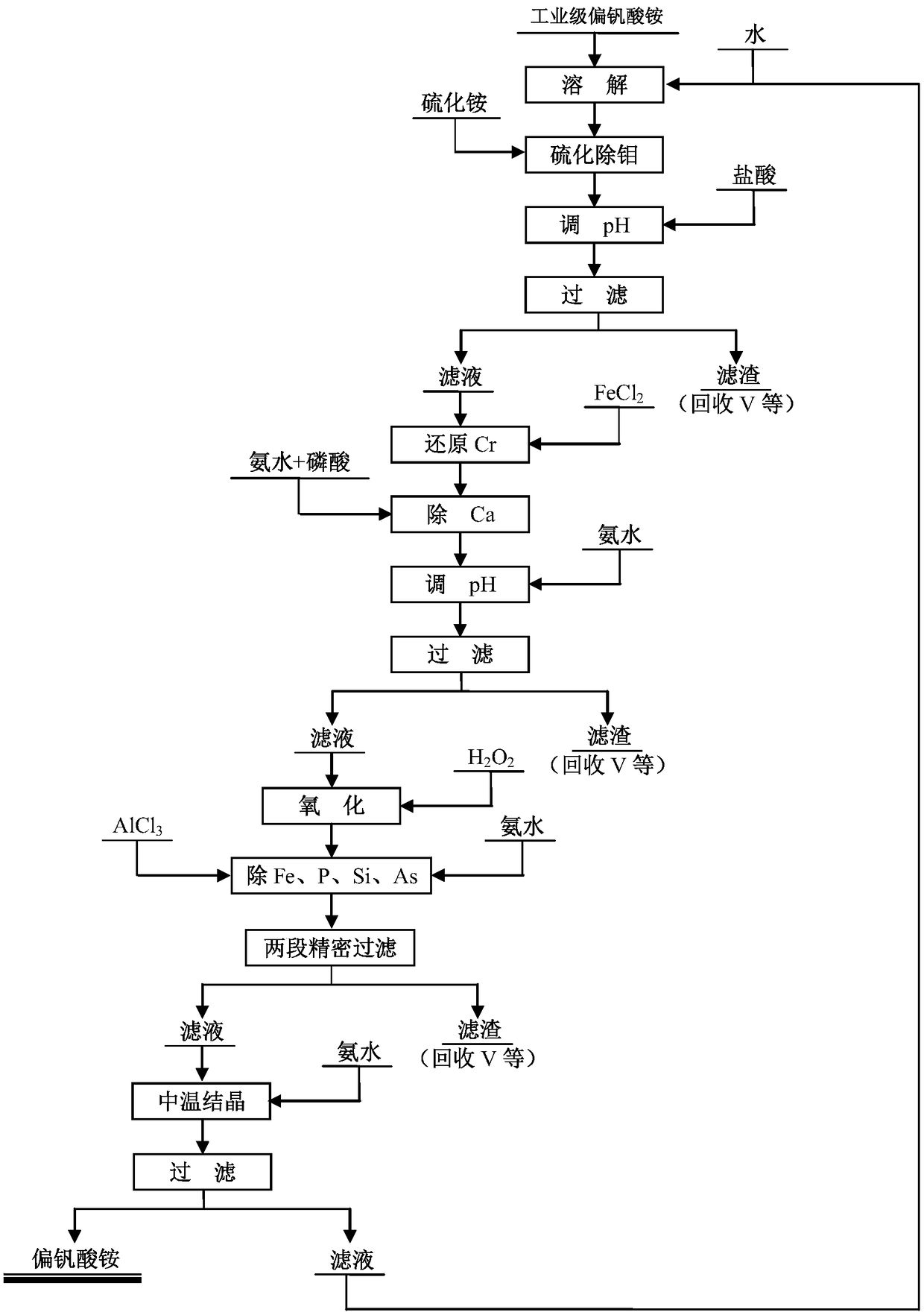

[0030] Embodiment 1: as figure 1 Shown, the industrial grade ammonium metavanadate of the present embodiment, its main component is (%): NH 4 VO 389.26, Al 0.037, Cr 0.053, Fe 0.24, Ca 0.26, P 0.18, As 0.14, Si 0.066, Mo 0.48, Cl 0.081, K 0.068, Na 0.36, S 0.002, Pb2 ·6H 2 0.6g, reacted for 30min, then added the mixed solution of 10ml ammonia water and 1.2ml phosphoric acid, added ammonia water to adjust the pH to 7.5-8.0, reacted for 30min, filtered, the filter residue recovered vanadium, and the filtrate entered the next process; Next, add 2mlH 2 o 2 React for 30min, add 12.15gAlCl 3 ·6H 2 O, add ammonia water to adjust the pH to 7.5-8.0, react for 120 minutes, filter, and recover vanadium from the filter residue, and the filtrate enters the crystallization link. After removing impurities, add ammonia water to adjust the pH to 8.5-9.0, stir and crystallize at 50°C for 12 hours, wash the crystallized product with deionized water at the same temperature for 3-4 times, an...

Embodiment 2

[0031] Embodiment 2: the technical grade ammonium metavanadate of the present embodiment, its main component is (%): NH 4 VO 3 89.26, Al0.037, Cr0.053, Fe0.24, Ca0.26, P0.18, As0.14, Si0.066, Mo0.48, Cl0.081, K0.068, Na0.36, S0.002, Pb2 ·6H 2 0.6g, reacted for 30min, then added the mixed solution of 10ml ammonia water and 1.2ml phosphoric acid, added ammonia water to adjust the pH to 7.5-8.0, reacted for 30min, filtered, the filter residue recovered vanadium, and the filtrate entered the next process; Next, add 2mlH 2 o 2 React for 30min, add 12.15gAlCl 3 ·6H 2 O, add ammonia water to adjust the pH to 7.5-8.0, react for 120 minutes, filter, and recover vanadium from the filter residue, and the filtrate enters the crystallization link. After removing impurities, add ammonia water to adjust the pH to 8.5-9.0, stir and crystallize at 50°C for 12 hours, wash the crystallized product with deionized water at the same temperature for 3-4 times, and dry the filter cake at 30-35°...

Embodiment 3

[0032] Embodiment 3: the industrial grade ammonium metavanadate of the present embodiment, its main component is (%): NH 4 VO 3 89.26, Al0.037, Cr0.053, Fe0.24, Ca0.26, P0.18, As0.14, Si0.066, Mo0.48, Cl0.081, K0.068, Na0.36, S0.002, Pb2 ·6H 2 0.6g, reacted for 30min, then added the mixed solution of 10ml ammonia water and 1.2ml phosphoric acid, added ammonia water to adjust the pH to 7.5-8.0, reacted for 30min, filtered, the filter residue recovered vanadium, and the filtrate entered the next process; Next, add 2mlH 2 o 2 React for 30min, add 12.15gAlCl 3 ·6H 2 O, add ammonia water to adjust the pH to 7.5-8.0, react for 120 minutes, filter, and recover vanadium from the filter residue, and the filtrate enters the crystallization link. After removing impurities, add ammonia water to adjust the pH to 8.5-9.0, stir and crystallize at room temperature (20°C) for 12 hours, wash the crystallized product with deionized water at the same temperature for 3-4 times, and dry the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com