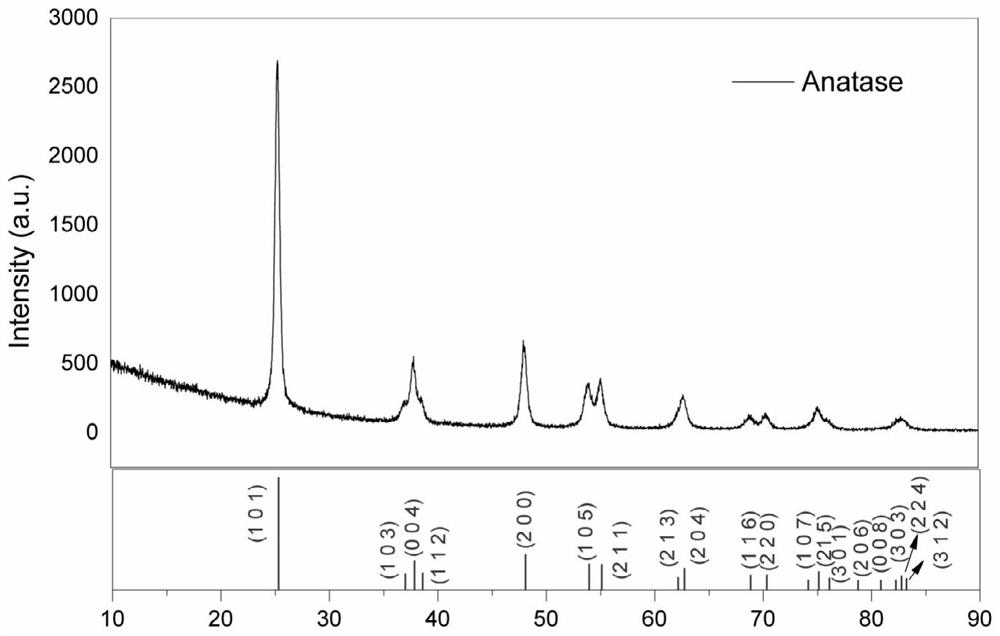

A silver-doped nanoanatase phase tio 2 Powder preparation method

A nano-anatase and silver doping technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of easy pollution of the environment, difficult control, high production cost, etc., and achieve simple and efficient process, high powder purity, The effect of increasing the doping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A silver-doped nano anatase phase TiO 2 The preparation method of powder, its implementation process is carried out according to the following steps successively:

[0029] (1) Prepare 10ml of sodium borohydride with a concentration of 1mol / L and 5ml of AgNO with a concentration of 2mol / L 3 solution, the AgNO 3 The solution was dropped into the sodium borohydride solution at a rate of 0.2ml / min to obtain a suspension;

[0030] (2) Weigh 2 g of titanium metal powder with a mass percentage of 99.9% and a particle size of 300 mesh, and mix it with 200 ml of deionized water to obtain a mixture of titanium powder and deionized water;

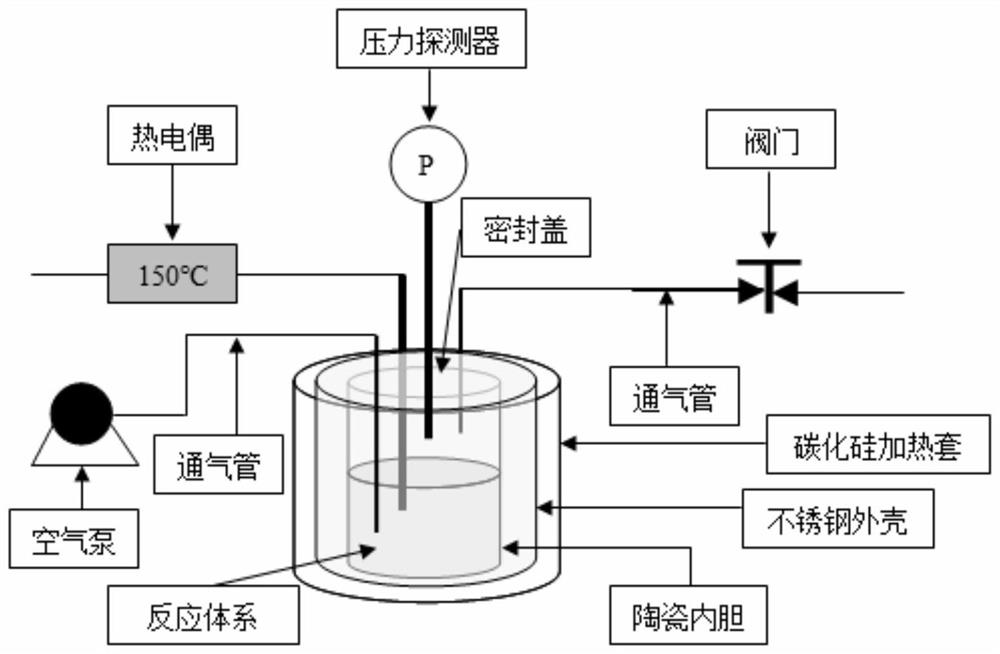

[0031] (3) Add the suspension to the mixture of titanium powder and deionized water, heat it from room temperature to 120°C in a temperature-controlled and pressure-controlled device, continuously feed air, keep the pressure at 8 MPa, and keep it warm for 5 hours to obtain a solid-liquid mixture;

[0032] (4) Centrifuge the obtained solid-li...

Embodiment 2

[0035] A silver-doped nano anatase phase TiO 2 The preparation method of powder, its implementation process is carried out according to the following steps successively:

[0036] (1) Prepare 10ml of sodium borohydride with a concentration of 1mol / L and 5ml of AgNO with a concentration of 2mol / L 3 solution, at 10 °C the AgNO 3 The solution was dropped into the sodium borohydride solution at a rate of 0.5ml / min to obtain a suspension;

[0037] (2) Weigh 2 g of titanium metal powder with a mass percentage of 99.93% and a particle size of 400 mesh, and mix it with 400 ml of deionized water to obtain a mixture of titanium powder and deionized water;

[0038] (3) Add the suspension to the mixture of titanium powder and deionized water, heat it from room temperature to 170°C in a temperature-controlled and pressure-controlled device, continuously feed air, keep the pressure at 10MPa, and keep it warm for 6 hours to obtain a solid-liquid mixture;

[0039] (4) Centrifuge the obtaine...

Embodiment 3

[0042] A silver-doped nano anatase phase TiO 2 The preparation method of powder, its implementation process is carried out according to the following steps successively:

[0043] (1) Prepare 10ml of sodium borohydride with a concentration of 2mol / L and 5ml of AgNO with a concentration of 2.5mol / L 3 solution, AgNO at 7 °C 3 The solution was dripped into the sodium borohydride solution at a rate of 0.3ml / min to obtain a suspension;

[0044] (2) Weigh 1 g of titanium metal powder with a mass percentage of 99.92% and a particle size of 400 mesh, and mix it with 150 ml of deionized water to obtain a mixture of titanium powder and deionized water;

[0045](3) Add the suspension to the mixture of titanium powder and deionized water, heat it from room temperature to 150°C in a temperature-controlled and pressure-controlled device, continuously feed air, keep the pressure at 9MPa, and keep it warm for 5.5h to obtain a solid-liquid mixture;

[0046] (4) Centrifuge the obtained solid-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com