Preparation method of carbon-coated gold-doped tin dioxide composite material

A technology of tin dioxide and composite materials, applied in the preparation/purification of carbon, tin oxide, metal material coating technology, etc., can solve the problems of low sensitivity of tin dioxide, high optimal response temperature, and small optimal response value To achieve the effect of improving the adsorption capacity and transmission capacity, increasing the maximum response value, and enhancing the gas-sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

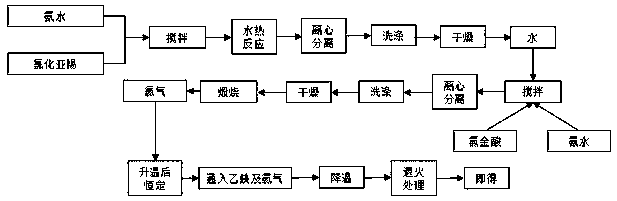

[0022] A method for preparing a carbon-wrapped gold-doped tin dioxide composite material, comprising the steps of:

[0023] S1. Preparation of tin dioxide: Add the ammonia solution into the tin protochloride aqueous solution, stir evenly, add it into the polytetrafluoroethylene reaction kettle, carry out the hydrothermal reaction, after the reaction is completed, obtain the solid through centrifugation , and then washed with deionized water until neutral, rinsed with ethanol, placed in an oven, and dried at a constant temperature to prepare tin dioxide;

[0024] S2. Preparation of gold-doped tin dioxide: add the tin dioxide prepared in step S1 into deionized water, and stir evenly. During the stirring process, add chloroauric acid solution and ammonia solution, chloroauric acid and ammonia water add The ratio of volume to deionized water is 1:3:6. After continuous stirring, the solid is obtained by centrifugation, and then washed with deionized water until neutral, then rinsed...

Embodiment 1

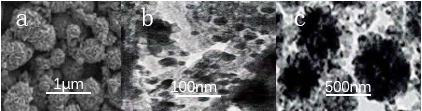

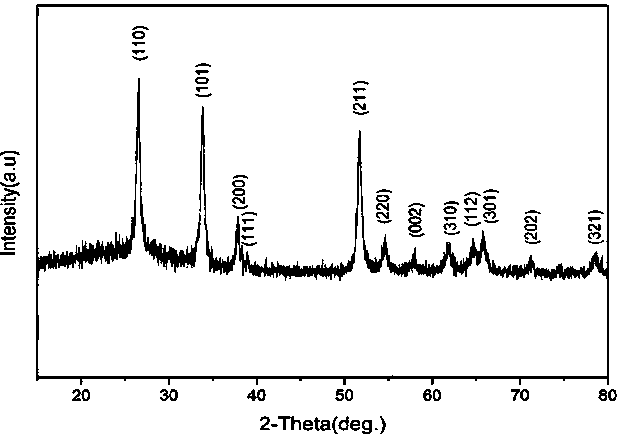

[0036] The tin dioxide SEM figure that step S1 prepares in embodiment 1 is as follows figure 2 Shown in middle a, as can be seen from the SEM figure, the prepared tin dioxide has a larger specific surface area, and the prepared tin dioxide has a uniform size; the prepared tin dioxide X-ray diffraction pattern is as follows image 3 As shown, it can be seen from the X-ray diffraction pattern that all the main diffraction peaks (110), (101), (200), (211), (220), (002), (310), (112), (301 ), (202), (321) are consistent with the standard spectrum, and no miscellaneous peaks appear, indicating that the prepared tin dioxide is pure phase tin dioxide without impurities.

[0037] The TEM figure of the gold-doped tin dioxide prepared in step S2 in Example 1 is as follows figure 2 As shown in middle b, it can be seen from the TEM image that the gold particles generated on the surface of tin dioxide are uniform in size and uniformly dispersed on the surface of tin dioxide without aggl...

Embodiment 5

[0040] The carbon-wrapped gold-doped tin dioxide composite materials prepared in Examples 1-4 were respectively placed in an agate mortar, and an appropriate amount of deionized water was added to grind them into a homogeneous and fine slurry, and then coated on trioxide On the aluminum-based gold finger electrode, the sensing layer of the gas sensor is prepared by coating about 100um. After coating, it is dried in the shade, and then placed in the gas sensitivity tester to assemble a complete circuit to form a complete The gas sensor device was subjected to current aging for 24 hours, and the gas sensor prepared by the carbon-wrapped gold-doped tin dioxide composite material prepared in Examples 1-4 was tested for its gas sensitivity response to 100 ppm formaldehyde from 50°C to 230°C.

[0041] Figure 4 The line graph of the gas sensitivity response to 100ppm formaldehyde of the gas sensor prepared for the carbon-wrapped gold-doped tin dioxide composite material prepared in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com