Efficient simulated moving bed equipment and efficient simulated moving bed technology

A simulated moving bed, high-efficiency technology, applied in separation methods, chemical instruments and methods, solid adsorbent-liquid separation, etc., can solve problems such as large pressure fluctuations and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

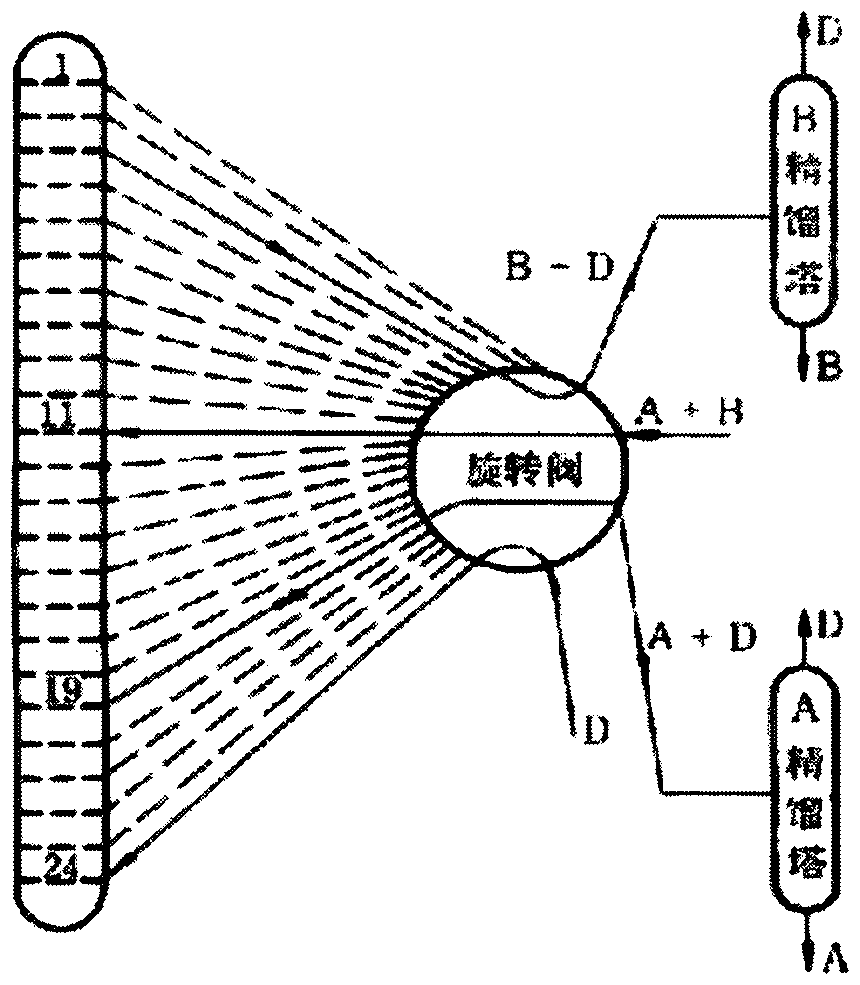

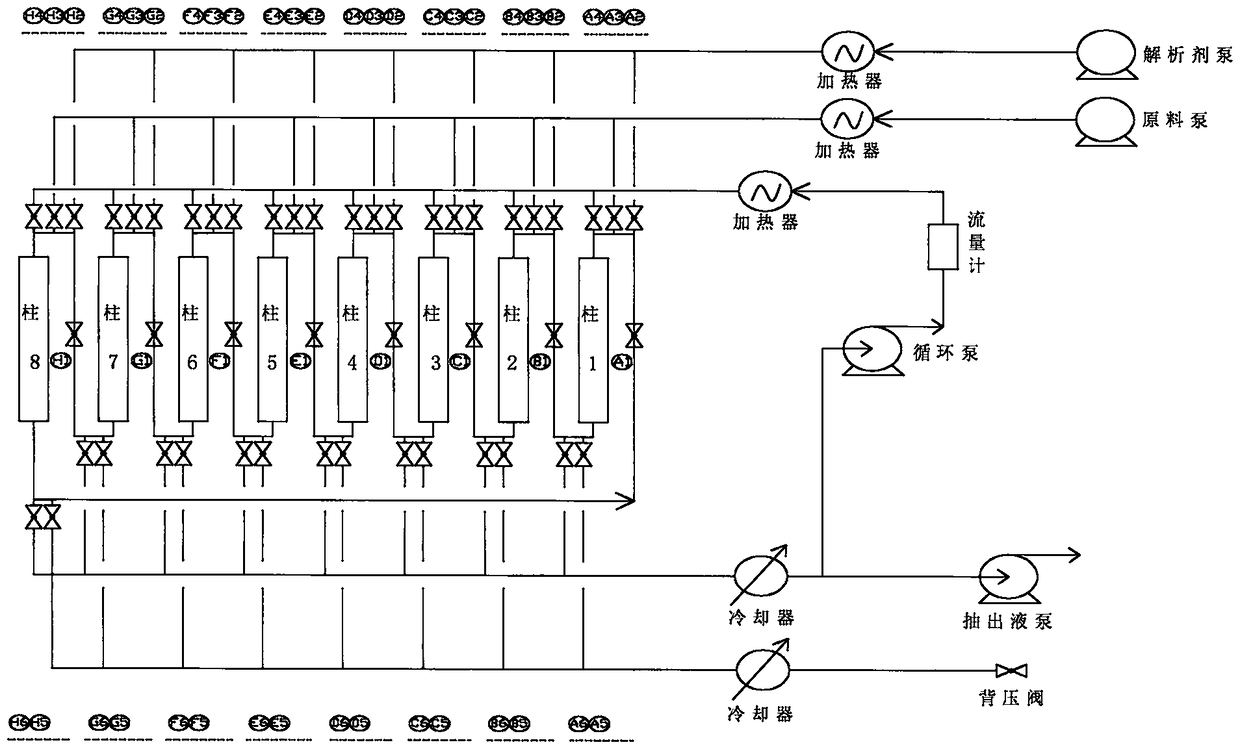

[0048] see figure 2 , taking the adsorption bed composed of 8 adsorption columns as an example.

[0049] A high-efficiency simulated moving bed equipment, including an adsorption bed, a raw material feeding system, a desorbing agent feeding system, a circulation system, an extraction liquid system, a raffinate system, a program-controlled valve group, and an automatic control system; wherein, the adsorption bed Several adsorption columns are divided into adsorption zone, purification zone, desorption zone and buffer zone (it should be pointed out that the present embodiment adopts the adsorption bed comprising adsorption zone, purification zone, desorption zone and buffer zone, but buffer zone is for In the present invention, it is not necessary to choose, but is optional);

[0050] The upper ends of the adsorption columns 1-8 are respectively provided with raw material feed valves A3, B3, C3, D3, E3, F3, G3, H3, and analytical agent feed valves A2, B2, C2, D2, E2, F2, G2, H...

Embodiment 2

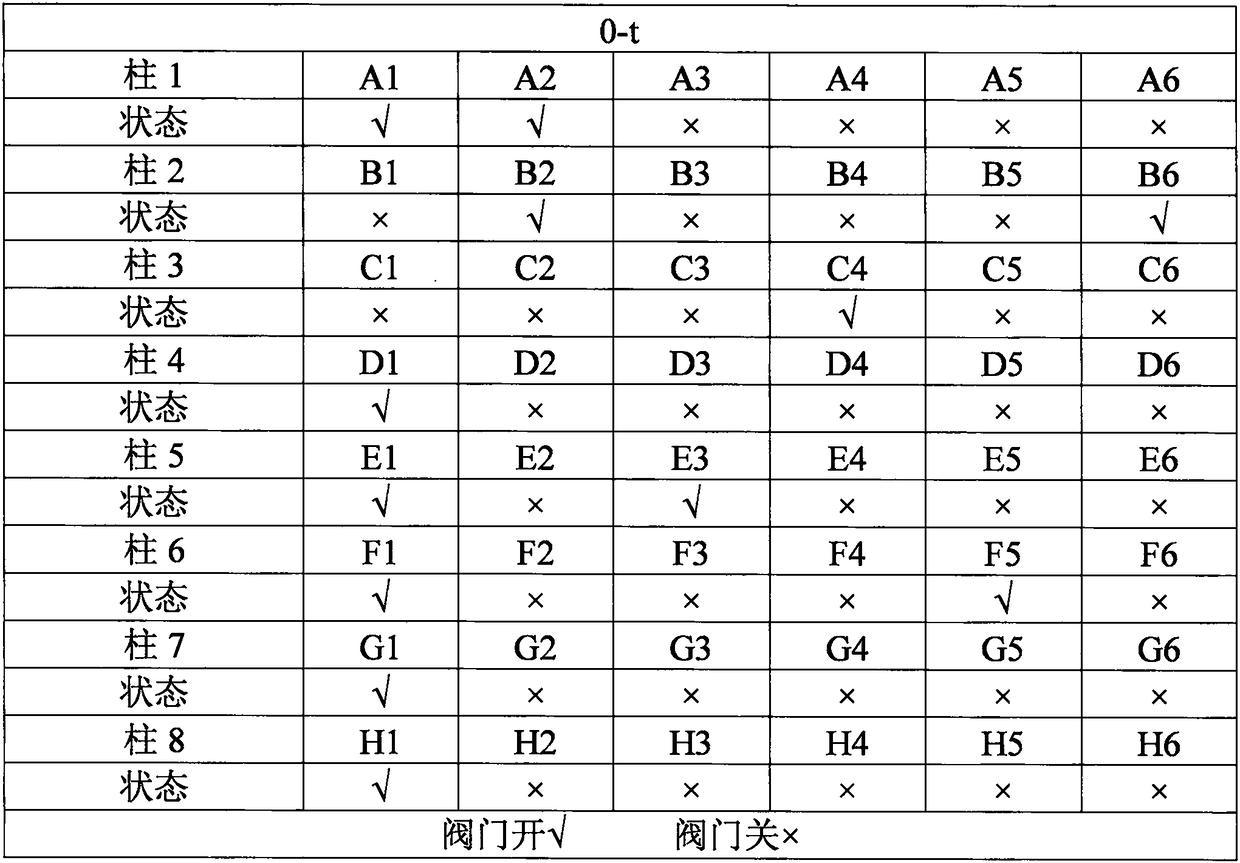

[0069] Adopt the simulated moving bed process of the simulated moving bed equipment of 8 adsorption columns of embodiment 1, control valve switching to change the position of feeding and discharging each time, realize the simulated movement of adsorption zone, purification zone, desorption zone, buffer zone. The specific program control steps are:

[0070] 0-t sequence, open the one-way valve A1 of the adsorption column 1, the desorbent feed valve A2, the desorbent feed valve B2 of the adsorption column 2, the extraction liquid discharge valve B6, and the circulating liquid feed valve C4 of the adsorption column 3 , one-way valve D1 of adsorption column 4, one-way valve E1 of adsorption column 5, raw material feed valve E3, one-way valve F1 of adsorption column 6, raffinate discharge valve F5, one-way valve G1 of adsorption column 7 1. The one-way valve H1 of the adsorption column 8 is opened, and the other valves are closed;

[0071] At this time, the adsorption area is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com