Coriolis mass flowmeter and sensor assembly thereof

A sensor assembly, Coriolis technology, applied in the field of Coriolis mass flowmeters, can solve problems such as poor stability of Coriolis flowmeters, and achieve the effects of enhancing linearity, improving stability, and increasing signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

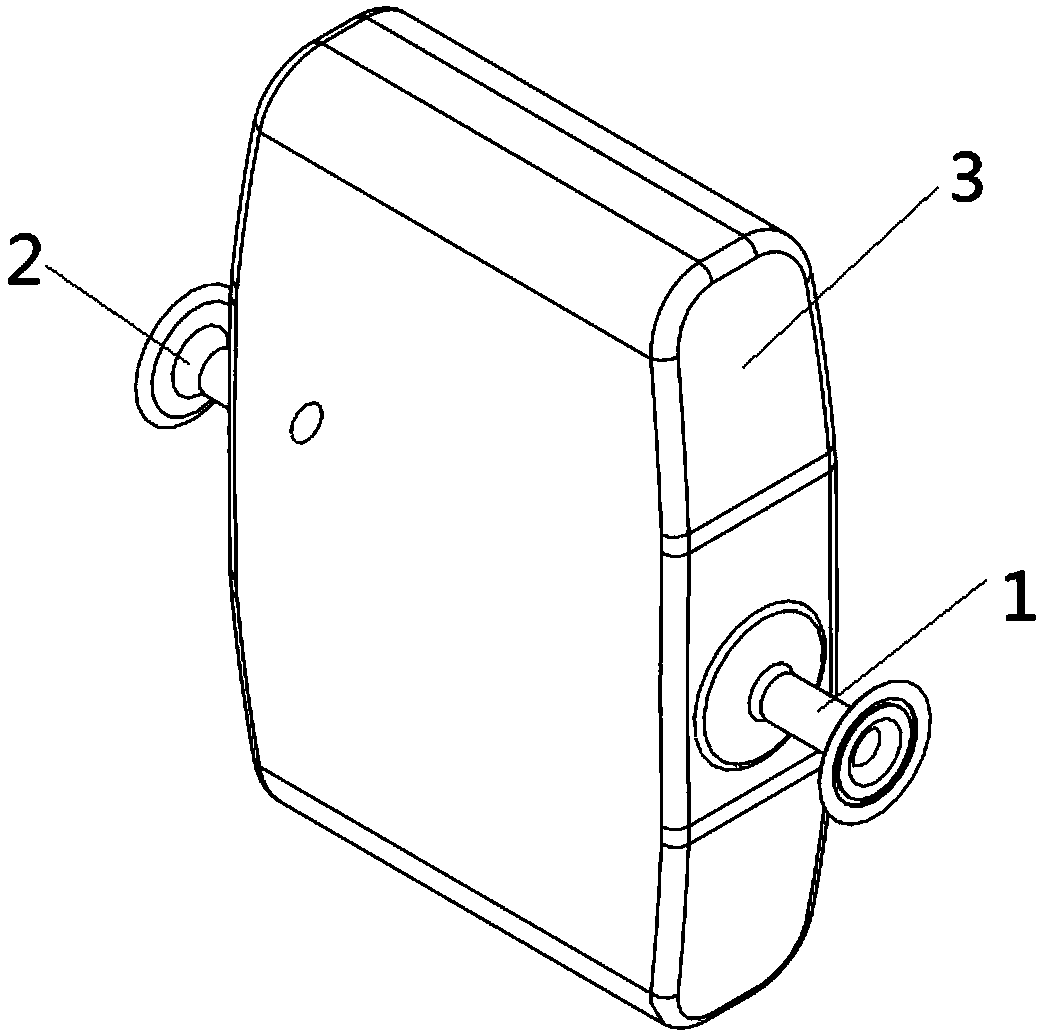

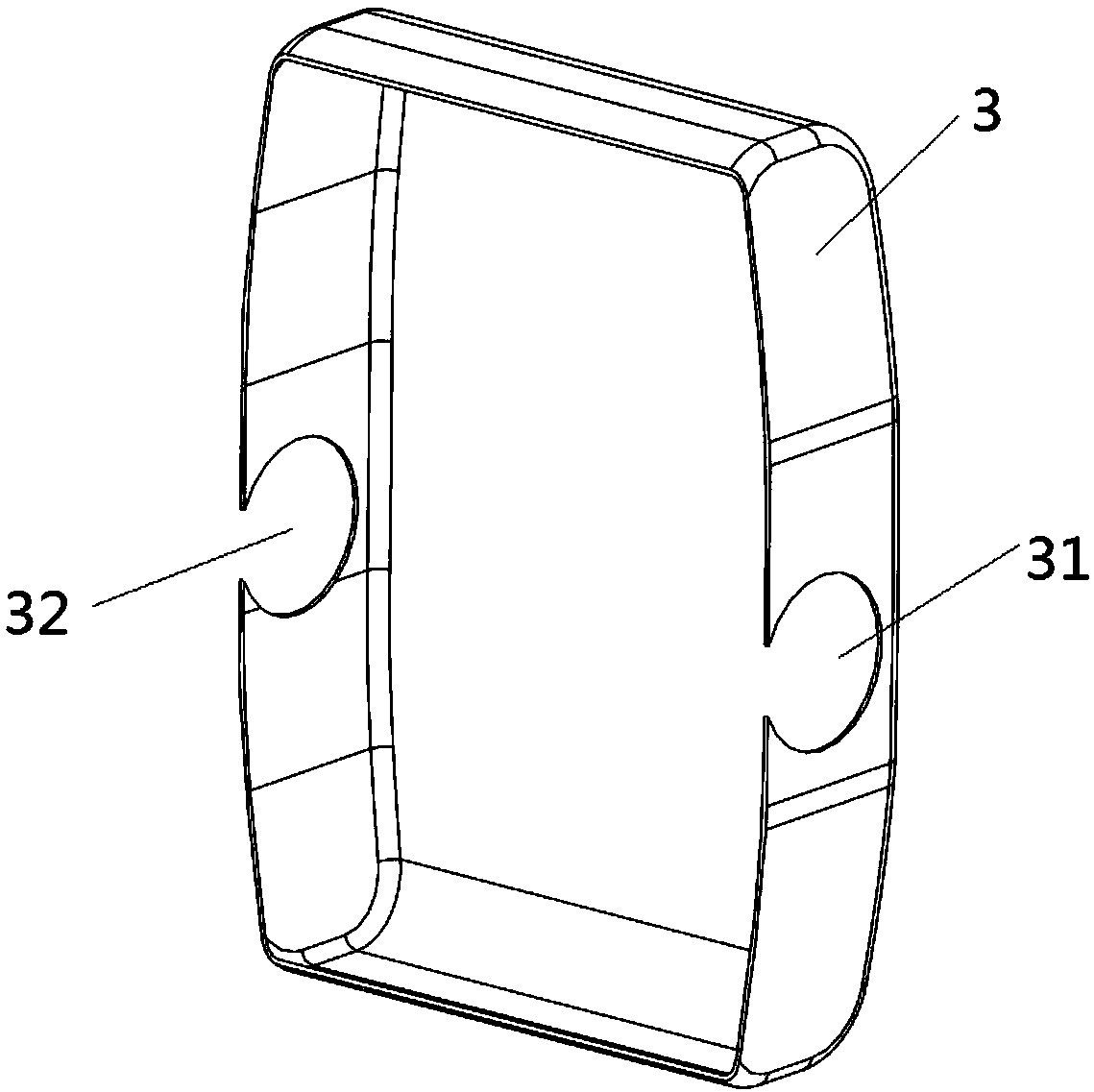

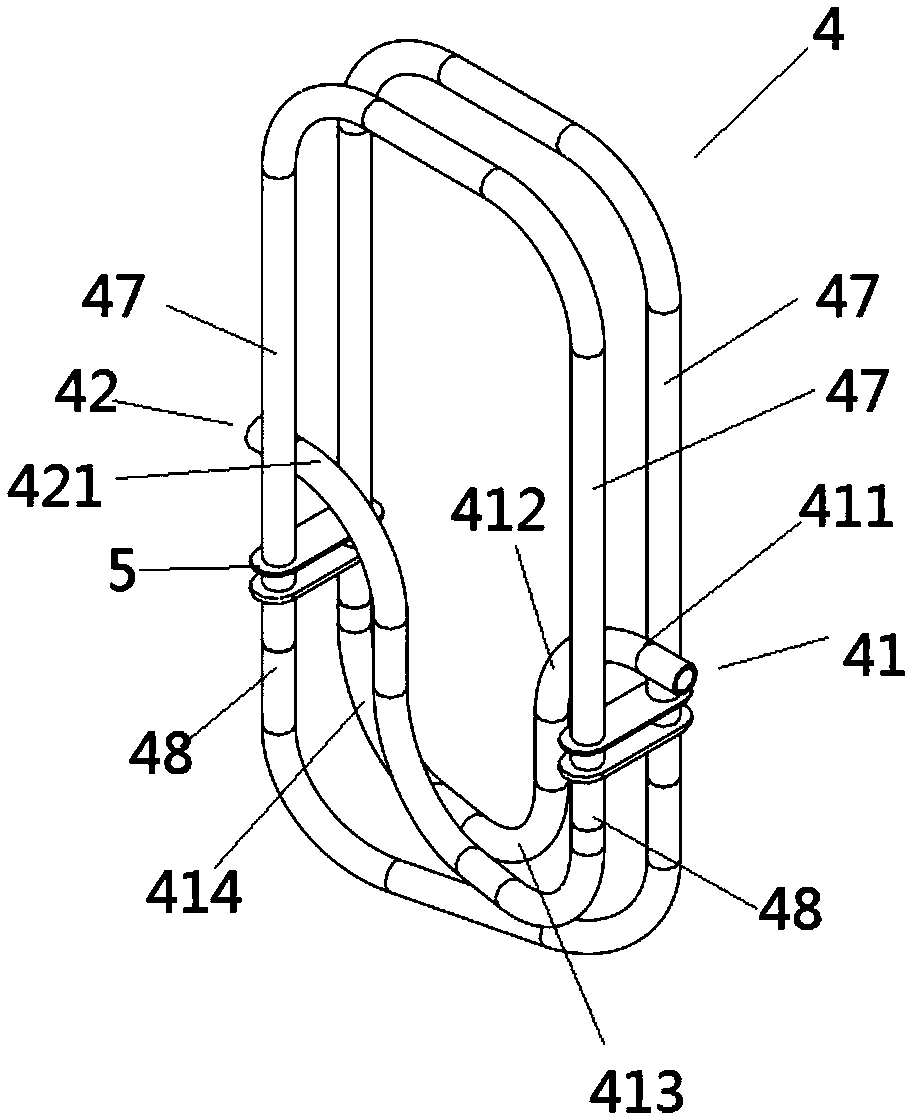

[0069] Such as Figure 1-4 As shown, this embodiment provides a Coriolis mass flowmeter, which includes an upstream pipe joint 1, a downstream pipe joint 2, a housing 3, a fluid flow pipe 4, an excitation device, a detection device, a vibration isolation structure and an increaser. Heavy structure7. Wherein, the fluid flow tube 4 is installed in the housing 3, and the vibration isolation device is installed on the fluid flow tube 4 to separate the fluid flow tube 4 into a vibrating pipeline 47 and a non-vibrating pipeline 48. The fluid flow tube 4 An excitation device and a detection device are also installed on it. The excitation device is used to drive the vibrating pipeline 47 to vibrate. When the fluid material is introduced into the tube to make it flow forward along the tube, the vibrating tube will force the fluid to vibrate together. In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com