Methods used for producing glucuronic acid, and special-purpose engineering bacteria of method

A technology of glucuronic acid and engineering bacteria, applied in the field of glucuronic acid production, can solve the problems of poor selectivity, low product yield, high energy consumption, etc., and achieve the effect of significant promotion and application value and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

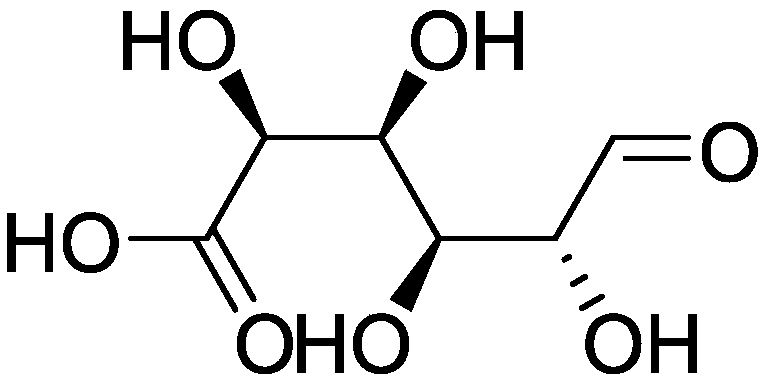

Image

Examples

Embodiment 1

[0046] Embodiment 1, the construction of recombinant bacteria

[0047] 1. Insert DNA molecule A (DNA molecule A is a double-stranded DNA molecule, composed of nucleotide C and sequence 2 in the sequence table from upstream to downstream) into the vector pBAD / HisB for XhoI and EcoRI digestion Between the sites, recombinant plasmid A was obtained. According to the sequencing results, the structure of the recombinant plasmid A is described as follows: DNA molecule A is inserted between the XhoI and EcoRI restriction sites of the vector pBAD / HisB. DNA molecule A and part of nucleotides on the carrier form fusion gene A to express fusion protein A.

[0048] 2. Insert DNA molecule B (DNA molecule B is a double-stranded DNA molecule, composed of nucleotide C and sequence 4 in the sequence table from upstream to downstream) into the vector pBAD / HisB for XhoI and EcoRI digestion Between the sites, the recombinant plasmid B was obtained. According to the sequencing results, the struc...

Embodiment 2

[0053] Embodiment 2, the preparation of albumen

[0054] The test strains were respectively: recombinant bacteria I, recombinant bacteria II or recombinant bacteria III prepared in Example 1.

[0055] 1. Take a single clone of the test strain, inoculate it into liquid LB medium containing 50 μg / mL streptomycin, and culture it with shaking at 37°C and 220 rpm until OD 600nm =0.6~0.8.

[0056] 2. After completing step 1, add L-arabinose to the culture system to make the concentration 0.2g / 100mL, shake and culture at 30°C and 200rpm for 12 hours.

[0057] 3. After completing step 2, take the entire culture system, centrifuge at 4°C and 6000rpm for 15min, and collect the bacterial precipitate.

[0058] 4. Take the bacterial pellet obtained in step 3, resuspend in buffer A and perform ultrasonic disruption, then centrifuge at 10,000rpm for 30min, and collect the supernatant.

[0059] Buffer A (pH8.0): contains 50mmol / L Tris-HCl and 100mmol / LNaCl, and the balance is water.

[00...

Embodiment 3

[0068] Embodiment 3, the enzyme activity assay of protein

[0069] The protein solution to be tested is the protein solution I, protein solution II or protein solution III prepared in Example 2.

[0070] 1. Detect the protein concentration of the protein solution to be tested.

[0071] 2. Detect the enzyme activity of the protein solution to be tested

[0072] The reaction system consists of the protein solution to be tested, L-cysteine, inositol, ferrous sulfate (providing Fe 2+ ) and buffer composition. The buffer was Tris-HCl buffer, pH 8.0, 50 mM. In the reaction system, the protein concentration is 100μg / mL (the only source of protein is the protein solution to be tested), the concentration of L-cysteine is 2mmol / L, Fe 2+ The concentration of inositol is 1mmol / L, and the concentration of inositol is 20mmol / L.

[0073] Reaction conditions: stand at 37°C for 30 minutes.

[0074] After the reaction was finished, a sample was taken, diluted to 10 times the volume with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com