Boron absorptive material and its preparing method

A technology of adsorption material and porous material, which is applied in the field of composite material preparation and adsorption separation, can solve the problem of limiting the application of adsorption method, reducing the surface utilization rate of high polymer carrier, thermal stability, mechanical stability and solvent resistance of high polymer carrier Poor performance and other problems, to achieve the effect of high yield, high surface modification ratio and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

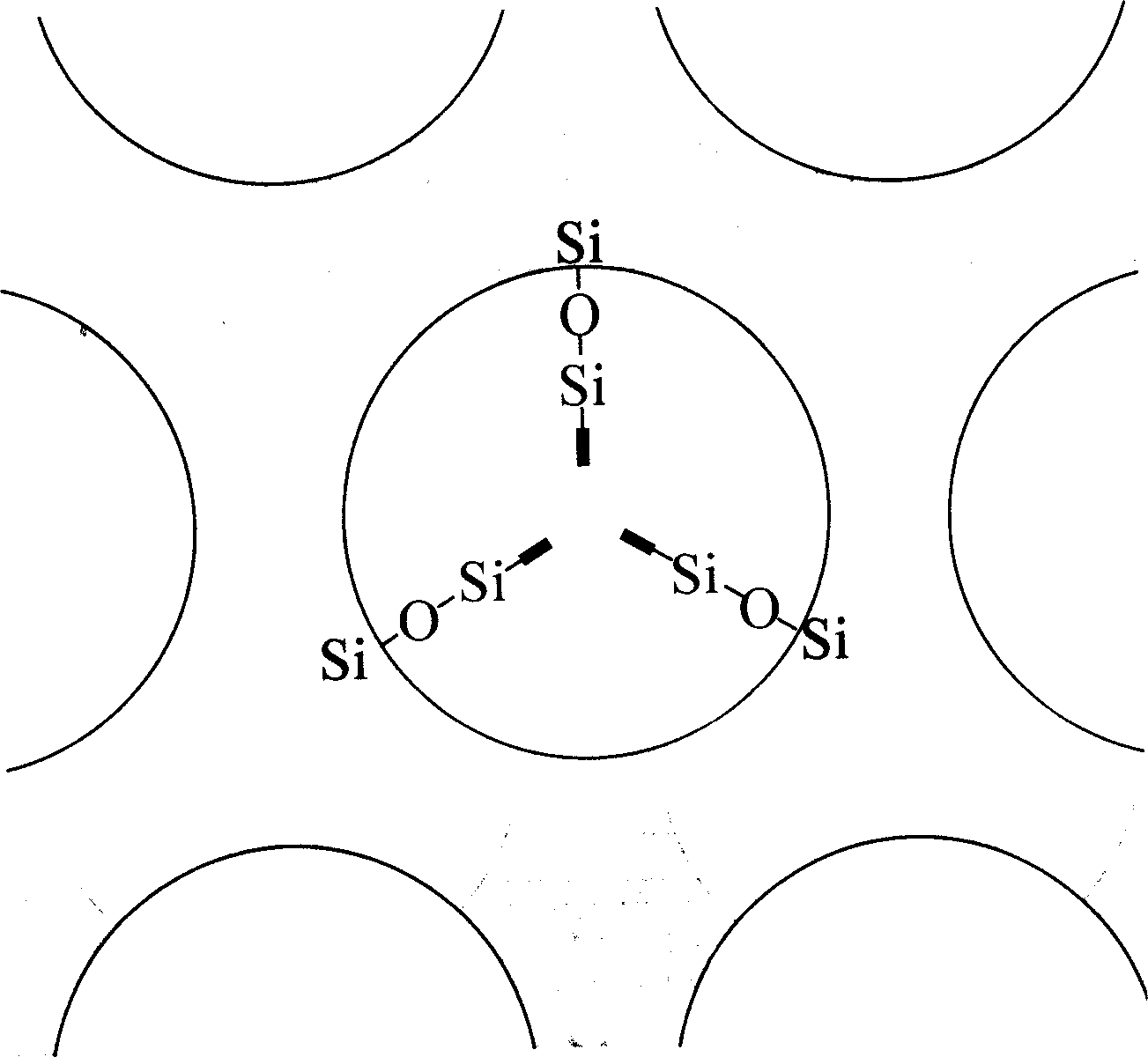

Method used

Image

Examples

Embodiment 1

[0048] Using silica gel as the adsorbent carrier, the carrier has micropores, mesopores and macropores, with an average pore diameter of 8.5nm and a specific surface area of 512m 2 / g, the pore volume is 1.1ml / g. 10g of silica gel and 10g of γ-aminopropyltriethoxysilane were refluxed in 200ml of toluene solvent for 6 hours to obtain an intermediate product, and then 10g of the intermediate product was reacted with 20g of glucose in 200ml of methanol for 10 hours. The reaction process was performed with N 2 protection, the light yellow boron adsorption material was prepared, with an average pore size of 4.5nm and a specific surface area of 334m 2 / g, pore volume 0.67ml / g.

[0049] Take 0.1g of this adsorption material, add 10ml of Qinghai Chaerhan Salt Lake brine with a pH value of 5.05 and boron content of 267ppm, and after equilibrating for 24 hours, use the ICP-AES method to detect the concentration of boron in the brine before and after adsorption. The boron adsorption...

Embodiment 2

[0051] Using cetyltrimethylammonium bromide (CTAB) as template, tetraethyl orthosilicate (TEOS) as organosilicon source, ethanol (EtOH) and water as solvent, and ammonia water to adjust the pH value of the system, synthesized Ordered silicon-based mesoporous material MCM-41. Under mechanical stirring, the silicon source was added into the template agent aqueous solution, stirred at room temperature for 1 hour, and then statically crystallized at 80° C. for 24 hours. Filter and wash with deionized water until neutral. Calcined at 540° C. for 4 hours to obtain a mesoporous silica carrier. The carrier has a most probable pore diameter of 2.5nm and a specific surface area of 1260m 2 / g. 2g of the carrier was first reacted with 5g of γ-aminopropyltriethoxysilane in 50ml of dichloromethane solvent under reflux for 6 hours to obtain an intermediate product, and then 2g of the intermediate product was reacted with 7g of glucose in 80ml of ethanol for 10 hours, and the reaction pr...

Embodiment 3

[0054] Using Pluronic P123 as the template, cetyltrimethylammonium bromide (CTAB) as the co-template, tetraethyl orthosilicate (TEOS) as the organic silicon source, water as the solvent, and hydrochloric acid to adjust the pH value of the system , Synthesis of ordered silicon-based mesoporous material SBA-15. Under mechanical stirring, the silicon source was added into the aqueous template solution, stirred at room temperature for 20 hours, and then crystallized at rest for 24 hours. Filter, wash with deionized water until neutral, dry at room temperature, and bake at 550°C for 4 hours to obtain the SBA-15 carrier. The carrier has a most probable pore diameter of 6.5nm and a specific surface area of 1007m 2 / g. React 2g of the carrier with 10g of γ-chloropropyldimethylmethoxysilane in 100ml of n-hexane at room temperature for 48 hours to obtain a chloropropyl-containing intermediate, then mix 2g of the intermediate with 5g of N-methylglucamine in 50ml Reflux reaction in d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com