Preparation method of micrometer grade spherical cobaltosic oxide material

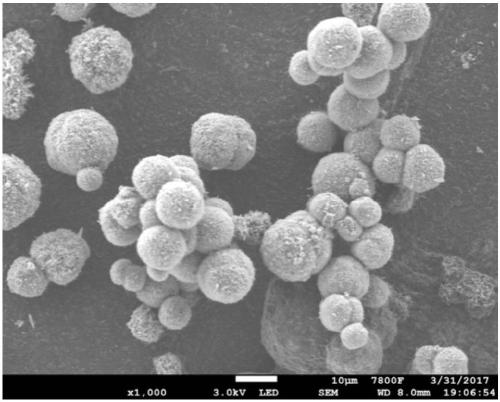

A micron-level technology of cobalt tetroxide, applied in the field of micro-nano materials, can solve the problems of cumbersome pollen pretreatment process and low product sphericity, and achieve the effect of high sphericity, high purity and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dissolve 25mmol cobalt sulfate heptahydrate, 5g PEG-200 and 20ml n-propanol in 100ml deionized water to form solution A; pour solution A into a 100ml agglomerated tetrafluoroethylene-lined reactor with a filling degree of 70%, Place it in an oven at 180°C for 10 hours. After the reaction, the product obtained is washed, filtered, dried overnight at 70°C in a vacuum, and then calcined at 500°C for 2 hours to obtain micron-sized spherical cobalt tetroxide, denoted as S-1.

Embodiment 2

[0033]Dissolve 400mmol cobalt nitrate hexahydrate, 35g PEG-200 and 80ml n-dodecanol in 100ml deionized water to form solution A; pour solution A into a 100ml agglomerated tetrafluoroethylene-lined reactor, fill temperature of 70%, placed in an oven at 220°C to react for 20h, the product obtained after the reaction was washed, filtered, dried overnight at 50°C in vacuum, and then calcined at 400°C for 3h to obtain micron-sized spherical cobalt tetroxide, denoted as S-2 .

Embodiment 3

[0035] Dissolve 5mmol cobalt acetate tetrahydrate, 0.5g PEG-10000 and 5ml decanol in 100ml deionized water to form solution A; pour solution A into a 100ml agglomerated polytetrafluoroethylene-lined reactor with a filling degree of 70% , placed in an oven at 150°C for 12 hours, the product obtained after the reaction was washed, filtered, dried overnight at 90°C in vacuum, and then calcined at 300°C for 5 hours to obtain micron-sized spherical cobalt tetroxide, denoted as S-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com