Metal lithium composite cathode as well as preparation method and application thereof

A metal lithium and metal lithium layer technology, which is applied in electrode manufacturing, electrode rolling/calendering, battery electrodes, etc., can solve the problems of easy flying of lithium powder, powder failure of negative electrode sheets, uneven thickness, etc., to improve charging and discharging. Efficiency, improving the density of the negative electrode, and the effect of uniform and flat lithium layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] As an aspect of the technical solution of the present invention, it relates to a method for preparing a metal lithium composite negative electrode, which includes:

[0023] At least using a vacuum physical deposition method to deposit a metal lithium layer on the surface of the polymer film to obtain a composite belt;

[0024] A composite tape is set on both sides of a negative electrode sheet, and the metallic lithium layer in each composite tape is in contact with the negative electrode sheet, and then pressure is applied to the composite structure composed of the negative electrode sheet and the composite tape to obtain both sides A negative electrode sheet combined with a lithium metal layer is the metal lithium composite negative electrode.

[0025] In some embodiments, the preparation method includes: at least using a magnetron sputtering method or an evaporation method to deposit a lithium metal layer on the surface of the polymer film.

[0026] Further, the material of ...

Embodiment 1

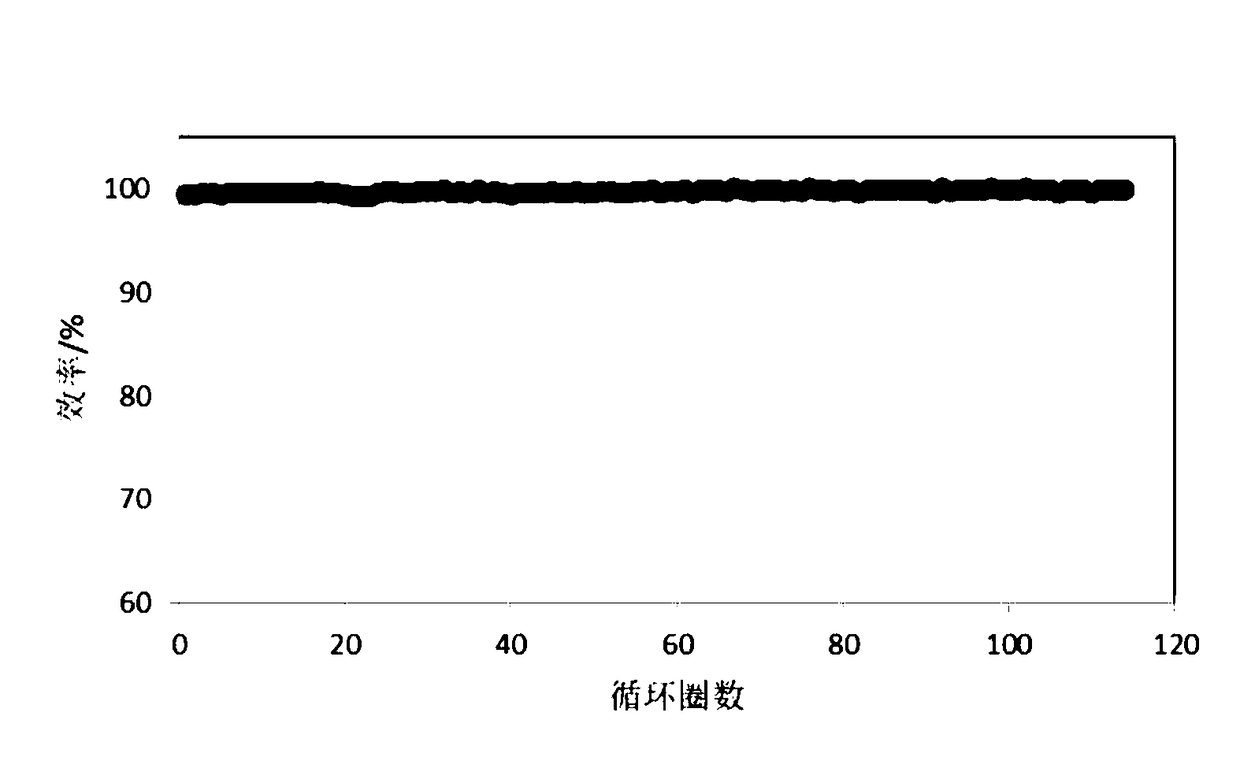

[0050] Apply white oil evenly on the PI (polyimide) film as a base material for vacuum evaporation of lithium. A vacuum evaporation equipment is used to deposit a 1 μm lithium metal layer on the PI film to obtain a lithium metal / PI film. Then like figure 1 As shown, the upper and lower two bands of metal lithium / PI film are rolled together with the graphite negative electrode, the rolling pressure is 0.1 MPa, and the rolling speed is 0.1 m / min. Lithium metal adheres to the negative electrode. Finally, the PI film was peeled off to obtain a graphite negative electrode coated with 1μm lithium metal on both sides. The compact density of the graphite negative electrode reached 1.4g / cm. -3 . The graphite metal lithium composite negative electrode and the lithium iron phosphate positive electrode form a single cell with an energy density of 130wh / kg. The first charge and discharge efficiency of the negative electrode is increased to 99.9%, such as figure 2 Shown.

Embodiment 2

[0052] A small amount of lithium fluoride powder is sprayed on the PET (polyethylene terephthalate) film as a substrate for vacuum evaporation of lithium. A vacuum evaporation equipment was used to deposit a 45 μm lithium metal layer on the PET film to obtain a lithium metal / PET film. Then like figure 1 As shown, the upper and lower two belts of metal lithium / PET film and the hard carbon negative electrode are rolled together, the rolling pressure is 400 MPa, and the rolling speed is 60 m / min. Lithium metal adheres to the negative electrode, and finally the PET film is peeled off to obtain a hard carbon negative electrode coated with lithium metal of 45 μm on both sides. The hard carbon metal lithium composite negative electrode and the sulfur positive electrode are assembled into a single battery, which can work normally with an initial energy density of 500wh / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com