Large pipeline structure

A pipeline and large-scale technology, applied in the direction of large containers, pipeline protection, superstructure sub-assembly, etc., can solve the problems of weak welding between the honeycomb core and the upper and lower panels, unstable overall structure, poor impact resistance, etc., and achieve the assembly cycle short, maintain structural integrity, and have a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

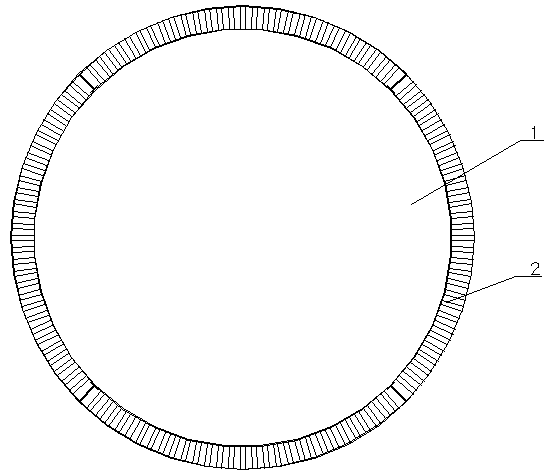

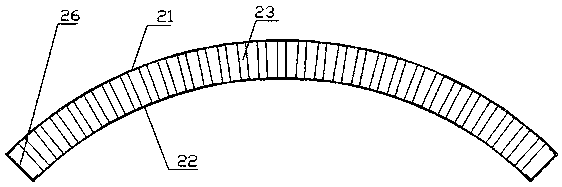

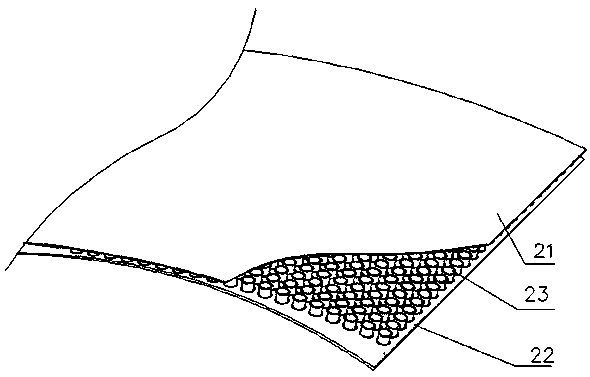

[0052] Such as Figure 1~Figure 5 As shown: a large-scale pipeline structure, including a pipeline body 1, which is composed of a plurality of metal plates 2 spliced together. The metal plate 2 comprises a first panel 21, a second panel 22 and a plurality of hollow tubes 23 arranged between the first panel 21 and the second panel 22, and a hollow tube 23 is arranged between the first panel 21 and the second panel 22. There is a brazing layer; the two ends of the hollow tube 23 are provided with flanging 25, which is turned out into a circular structure. The flanging 25 of the hollow tube is connected to the first panel 21 and the second panel 22 by soldering 24 .

[0053] Both the first panel 21 and the second panel 22 are curved panels. The two ends of the hollow tube 23 are vertically connected with the contact surface of the panel. The linetype of curved panels is arc. A plurality of hollow tubes 23 are arranged at intervals, and the axis of each hollow tube 23 is per...

Embodiment 2

[0060] Such as Figure 6 Shown: the difference with embodiment 1 is that the pipe body 1' is formed by splicing a plurality of metal plates 2'. Both the first panel 21' and the second panel 22' are plane plates, and the plane plates are cuboid plates. A plurality of metal plates 2' are spliced to form a rectangular parallelepiped pipeline.

[0061] Other structures are with embodiment 1.

Embodiment 3

[0063] The difference from Embodiment 1 is that the pipe body is composed of a plurality of metal plates spliced together. The first panel is an arc-shaped curved panel, the second panel is a flat panel, the flanging at one end of the hollow tube is parallel to the flat panel, and the flanging at the other end is an inclined surface, which is parallel to the contact surface of the curved panel, so that when When the hollow tube is connected to the two panels, there is no gap.

[0064] A plurality of metal plates are spliced to form a pipe with a circular cross-section of the outer ring and a square cross-section of the inner ring.

[0065] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com