Preparation method of wig fiber being suitable for wearing for long time

A fiber and wig technology, applied in the field of wig fiber preparation, can solve the problems of high price, difficult to obtain raw materials, slow growth of real hair, etc., and achieve the effect of improving flame retardant properties and excellent overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

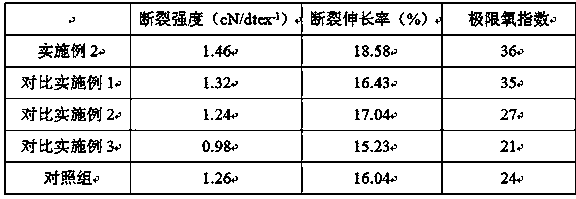

Examples

Embodiment 1

[0026] A method for preparing wig fibers suitable for long-term wear, comprising the steps of:

[0027] (1) Treatment of plant fibers:

[0028] a. Put loofah vines, pumpkin vines and red bean stalks into the pulverizer at a weight ratio of 3:4:1 for pulverization. The speed of the pulverizer is 800rpm, and the pulverization time is 30min. After pulverization, pass through an 80-mesh sieve spare;

[0029] b. Put the powder sieved in operation a into the numerical control continuous steam explosion machine for processing, the pressure in the steam explosion machine is controlled to 2.4MPa, after 5 minutes of steam explosion treatment, take out the powder for later use;

[0030] c. Put the powder and ionic liquid after the steam explosion treatment in operation b into the round bottom flask according to the mass volume ratio of 1g:40mL, and then place the round bottom flask in the water bath for heating to keep the temperature in the water bath At 83°C, continue heating until t...

Embodiment 2

[0044]A method for preparing wig fibers suitable for long-term wear, comprising the steps of:

[0045] (1) Treatment of plant fibers:

[0046] a. Put loofah vines, pumpkin vines and red bean stalks together into the pulverizer according to the weight ratio of 3.5:5:1.5 for pulverization. The speed of the pulverizer is 850rpm, and the pulverization time is 35min. After pulverization, pass through an 80-mesh sieve spare;

[0047] b. Put the powder sieved in operation a into the numerical control continuous steam explosion machine for processing, the pressure in the steam explosion machine is controlled to 2.5MPa, after steam explosion treatment for 5.5min, take out the powder for later use;

[0048] c. Put the powder and the ionic liquid after the steam explosion treatment in operation b into a round bottom flask according to the mass volume ratio of 1g:45mL, and then place the round bottom flask in a water bath for heating to maintain the temperature in the water bath At 85°C...

Embodiment 3

[0062] A method for preparing wig fibers suitable for long-term wear, comprising the steps of:

[0063] (1) Treatment of plant fibers:

[0064] a. Put loofah vines, pumpkin vines and red bean stalks into the pulverizer at a weight ratio of 5:6:2 for pulverization. The speed of the pulverizer is 900rpm, and the pulverization time is 40min. After pulverization, pass through an 80-mesh sieve spare;

[0065] b. Put the powder sieved in operation a into the numerical control continuous steam explosion machine for processing, the pressure in the steam explosion machine is controlled to 2.6MPa, after steam explosion treatment for 6 minutes, take out the powder for later use;

[0066] c. Put the powder and the ionic liquid after the steam explosion treatment in operation b into a round bottom flask according to the mass volume ratio of 1g:50mL, and then place the round bottom flask in a water bath for heating to maintain the temperature in the water bath At 87°C, continue heating un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com