Light-weight aluminum alloy material and application thereof in preparation of bullet shells

An aluminum alloy material, lightweight technology, applied in the field of bullets, can solve problems such as the inability to meet combat requirements, and achieve the effects of improving room temperature and high temperature mechanical properties, reducing weight, and refining crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of the lightweight aluminum alloy material comprises the following steps:

[0058] S1. Add aluminum to the smelting device, heat until the aluminum melts, add copper, manganese, zinc, titanium, chromium, rare earth, lithium, smelt, pass in protective gas, and refine;

[0059] S2. Spraying the melted material, heat treatment, and cooling to obtain the aluminum alloy material.

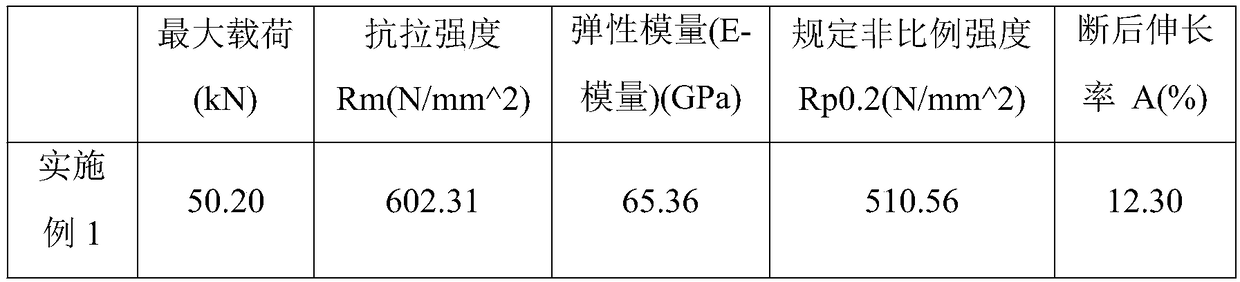

Embodiment 1

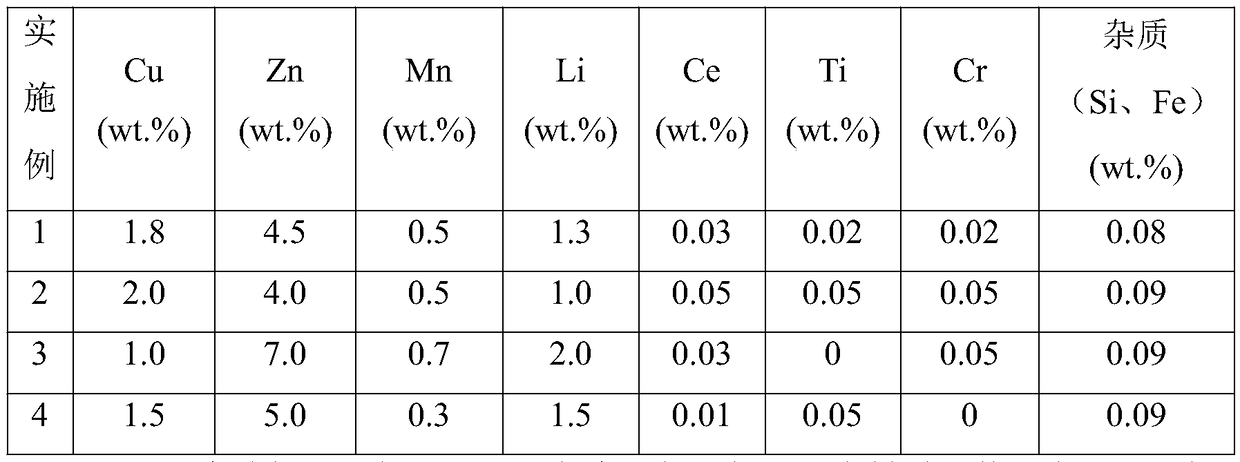

[0061] This example provides a method for preparing a high-strength and tough aluminum alloy material. The purity of all raw materials is above 99.9%. The composition content of the aluminum alloy material is shown in Table 1. The specific preparation steps are:

[0062] S1. Add aluminum with a purity of 99.99% to the smelting furnace, heat at 780°C until the aluminum is completely melted, then add copper, manganese, zinc, titanium, chromium, rare earth, and lithium in sequence, smelt for 45 minutes, introduce anhydrous nitrogen, and refine for 25 minutes;

[0063] S2. Spray molding the molten material, heat treatment at 460° C. for 1.5 h, and cool to obtain the aluminum alloy material.

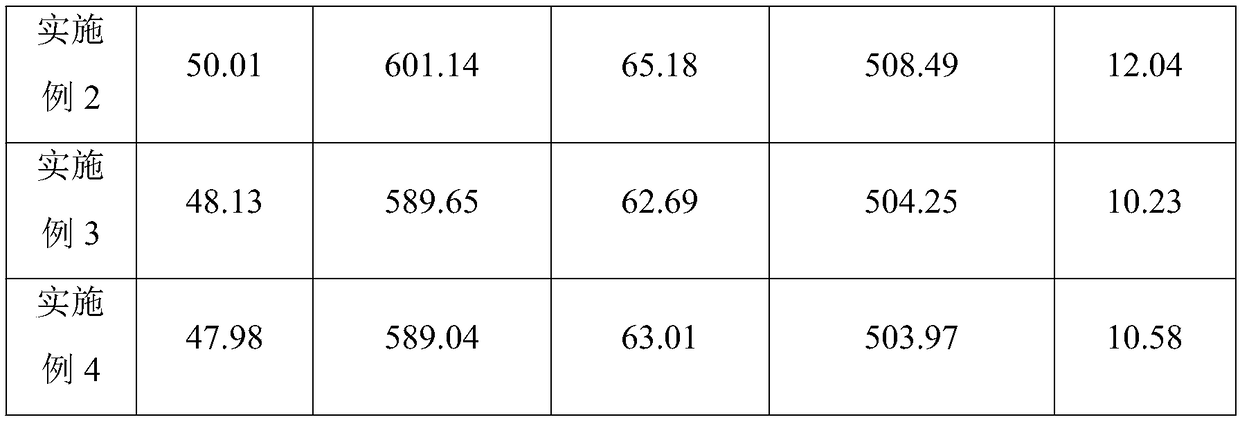

Embodiment 2

[0065] This example provides a method for preparing a high-strength and tough aluminum alloy material. The purity of all raw materials is above 99.9%. The composition content of the aluminum alloy material is shown in Table 1. The specific preparation steps are:

[0066] S1. Add aluminum with a purity of 99.99% to the smelting furnace, heat at 800°C until the aluminum is completely melted, then add copper, manganese, zinc, titanium, chromium, rare earth, and lithium in sequence, smelt for 60 minutes, and pass anhydrous nitrogen into it for 20 minutes of refining;

[0067] S2. Spray molding the molten material, heat treatment at 470° C. for 1.0 h, and cool to obtain the aluminum alloy material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com